Method for servo drive to control motor with one-way bearing function

A technology of servo drive and function, which is applied in the direction of motor generator/starter, single multi-phase induction motor starter, etc., can solve the problems of increasing motor cost and maintenance cost, and affecting the operation accuracy of equipment, so as to reduce manufacturing cost and Maintenance cost and the effect of ensuring operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

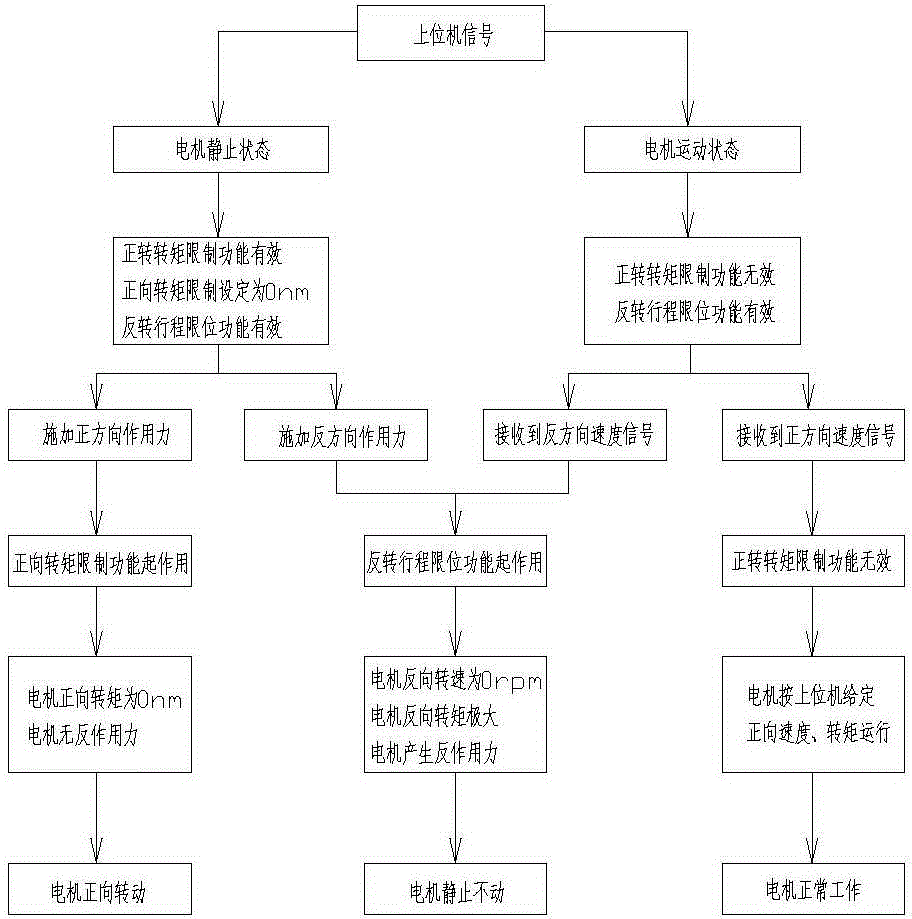

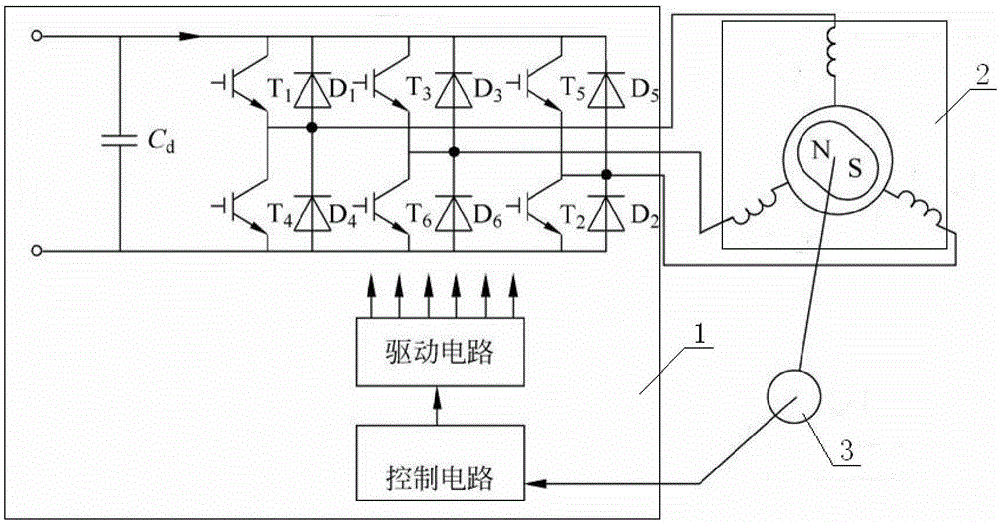

[0015] Such as figure 1 and figure 2 As shown, the method for the servo drive of the present invention to control the motor to have a one-way bearing function includes the following steps:

[0016] Step 1. Using the original external torque limit function and reverse stroke limit function of the servo drive, set the external forward torque limit parameter of the motor to 0nm (N*m) through the servo drive 1 parameter setting; the reverse stroke The limit signal input is always valid, so that the control mode of the servo driver 1 is that the motor 2 rotates in the positive direction and the reverse direction is locked, and the motor 2 rotates in the positive direction as a clockwise or counterclockwise signal;

[0017] Step 2. The upper computer outputs the command signal of the rotation state of the motor 2 to the servo driver 1, and the servo driver 1 controls the switching between the static state and the moving state of the motor 2; the external torque limiting function i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com