Shock absorption rubber air spring used for vehicle

A technology for damping rubber and air springs, applied in the direction of springs, shock absorbers, springs/shock absorbers, etc., can solve the problems of short service life, heat, excessive deformation and strain of rubber airbags, and improve service life and improve the Inflatable effect, the effect of reducing the local heating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

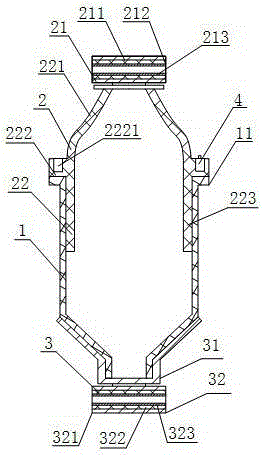

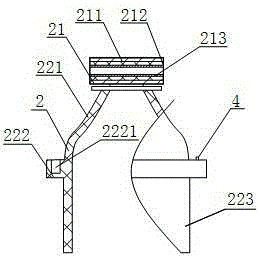

[0017] Such as figure 1 As shown, the shock-absorbing rubber air spring for vehicles includes a capsule-type main body 1, an upper shock-absorbing part 2 and a lower shock-absorbing part 3, and the upper shock-absorbing part 2 and the lower shock-absorbing part 3 are respectively connected to two ends of the bladder-type main body 1 and the upper shock-absorbing portion 2 includes an upper shock-absorbing column 21 and a buffer portion 22, the shock-absorbing column 21 is fixedly connected to the top position of the buffer portion 22, and the buffer portion 22 is a bottomless bottle shape at both ends, and its upper end is connected to the shock-absorbing portion. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com