Efficient and powerful wire drawing reducer

A wire-drawing reducer, a strong type of technology, applied in transmission parts, components with teeth, belts/chains/gears, etc., can solve the problem that the input part cannot bear large radial loads, the poor working environment of the reducer, and the prevention of The oil leakage design is not ideal enough to achieve the effect of ensuring long-term safe operation, good oil leakage prevention effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be introduced and illustrated in detail below by specific embodiments:

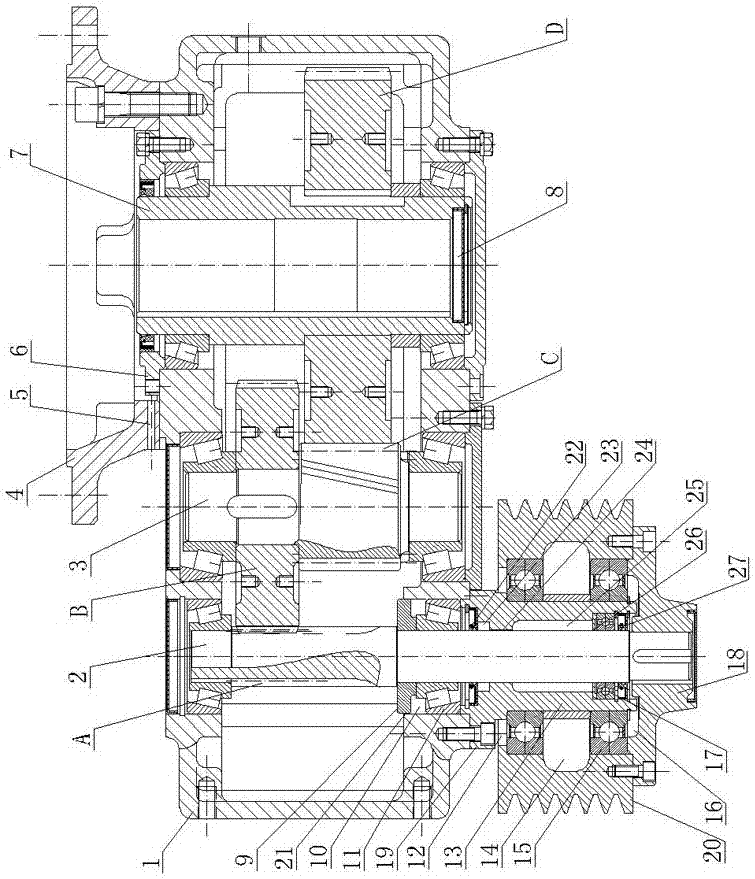

[0013] As shown in the figure, the strong wire drawing reducer of the present invention includes a reduction box 1, an input shaft 2, an intermediate shaft 3 and an output shaft 7, the input shaft 2, the intermediate shaft 3 and the output shaft 7 are vertically arranged in parallel, and the input shaft The gear A provided on 2 meshes with the gear B provided on the intermediate shaft 3, the gear C provided on the intermediate shaft 3 meshes with the gear D provided on the output shaft 7, and the lower shaft end of the input shaft 2 passes through the reduction box 1 and The pulley 20 is connected, and the middle section of the input shaft 2 is slewing supported by the tapered roller bearing 11 installed in the bearing installation hole 10 of the reduction box body. The bearing end cover 19 of the tapered roller bearing 11 is fixedly installed at the bottom of the reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com