Method for measuring viscoelasticity of gel particles

A gel particle and viscoelasticity technology, applied in the field of gel particle viscoelasticity evaluation, can solve the problems of long test time, decreased elasticity and strength, unable to truly reflect the gel particle viscoelasticity, etc., and achieve rich evaluation methods and test time. Short, the effect of improving test accuracy and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Gel particle 1# is produced by Daqing New Wantong Chemical Co., Ltd., and the particle size is 100-200 mesh; Magnetic stirrer (Changzhou Guohua Electric Co., Ltd.); Rheometer (MCR301 rheometer of AntonPaar, Austria), measuring The system is PP43 / GL-SN11457. Gel particle 1# is anionic gel particle, and the concentration of cross-linking agent is 0.21%.

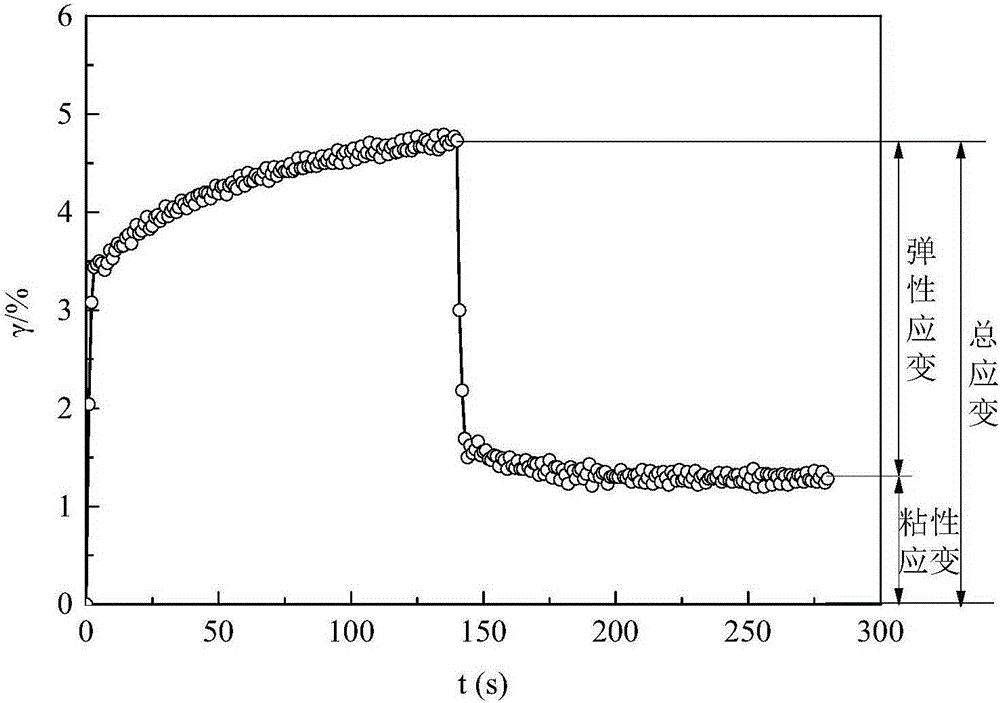

[0020] The method for measuring the viscoelasticity of gel particles includes the following steps. The first step is to prepare a dispersion system of gel particles to make them fully swell. In a beaker with a volume of 250mL, add 100mL of simulated formation water, put a magnetic rotor, put the beaker on the workbench of the magnetic stirrer, turn on the switch of the magnetic stirrer to make the magnetic rotor start to rotate, adjust the magnetic stirrer Turn the knob into the beaker to form a swirl of simulated formation water. Weigh gel particles 1# with a mass of 1 g, slowly add the gel particles to the vortex wal...

Embodiment 2

[0024] Gel particle 2# is produced by Daqing New Wantong Chemical Co., Ltd., and the particle size is 100-200 mesh; Magnetic stirrer (Changzhou Guohua Electric Co., Ltd.); Rheometer (MCR301 rheometer of AntonPaar, Austria), measuring The system is PP43 / GL-SN11457. Gel particle 2# is anionic gel particle, and the cross-linking agent concentration is 0.03%.

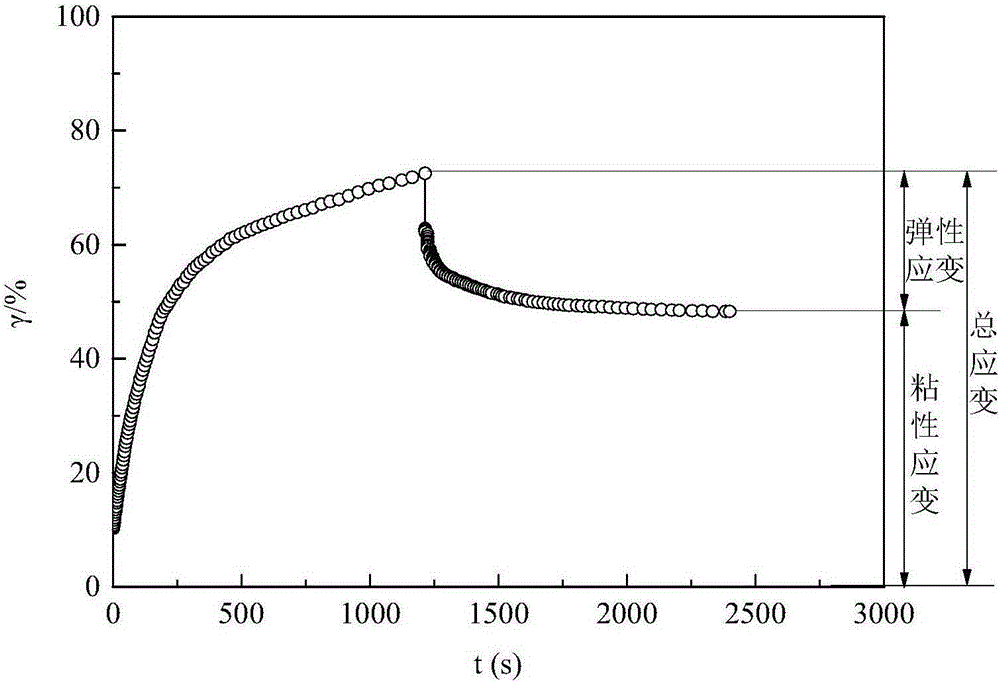

[0025] The method for measuring the viscoelasticity of gel particles includes the following steps. The first step is to prepare a dispersion system of gel particles to make them fully swell. In a beaker with a volume of 250mL, add 100mL of simulated formation water, put a magnetic rotor, put the beaker on the workbench of the magnetic stirrer, turn on the switch of the magnetic stirrer to make the magnetic rotor start to rotate, adjust the magnetic stirrer Turn the knob into the beaker to form a swirl of simulated formation water. Weigh gel particles 2# with a mass of 1 g, slowly add the gel particles to the vortex wall f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com