Maskless direct-writing photolithography machine suction cup structure with back surface alignment function

A backside alignment and maskless technology, which is applied in microlithography exposure equipment, photolithography exposure equipment, etc., can solve the problems of complex structure and high operation complexity, achieve ingenious layout, clear and accurate acquisition, and reduce operation complexity sex and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

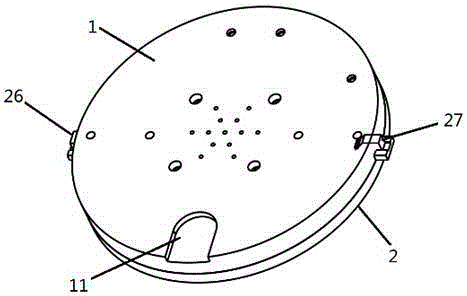

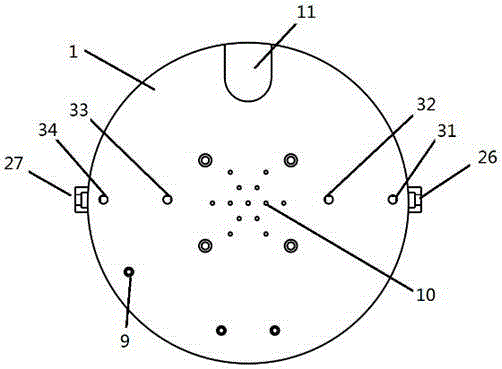

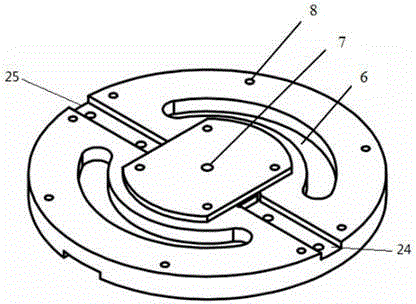

[0022] Such as figure 1 As shown, the suction cup structure of a maskless direct writing lithography machine with back alignment function described in the present invention includes an upper suction cup 1 and a lower suction cup 2, and the structure of the upper suction cup 1 is as follows image 3 Shown, the structure of lower sucker 2 is as follows Figure 4 As shown, both the upper suction cup 1 and the lower suction cup 2 are fixedly installed and formed together to form a suction cup body 5 . Such as figure 2 and image 3 As shown, the suction cup body 5 is provided with the required air passage 6, air extraction hole 7, Unicom hole 8, positioning hole 9 required for the positioning of the substrate 22, the suction hole 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com