An embedded magnetic lead screw with reduced output thrust pulsation

A magnetic lead screw, embedded technology, applied in the direction of electric components, electromechanical transmission devices, electrical components, etc., can solve the problems of large thrust pulsation of the magnetic lead screw, difficult processing of the permanent magnet of the magnetic lead screw, etc. Reduce process complexity and ensure the effect of thrust output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

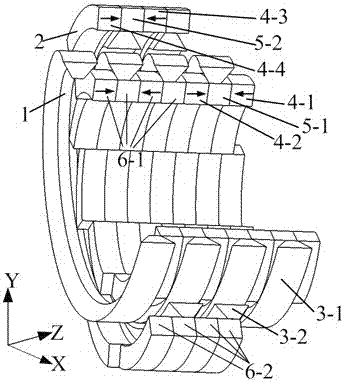

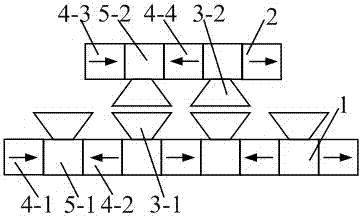

[0020] Such as figure 1 with figure 2 As shown, the present invention is made up of magnetic screw rod 1 and magnetic nut 2, and magnetic screw rod 2 is sleeved outside magnetic screw rod 1, and magnetic screw rod 1, magnetic nut 2 both are coaxial and have air gap between them, and magnetic wire Rod 1 moves linearly along the axis, that is, figure 1 The direction of the Z-axis in the linear motion, the magnetic nut 2 rotates with the Z-axis as the rotation center, and the two move at the same time.

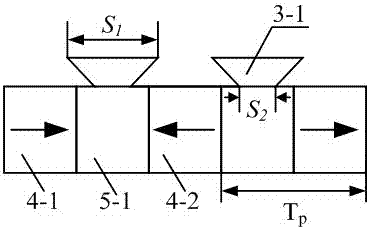

[0021] Magnetic screw mandrel 1 is made of a screw mandrel spiral electrical iron ring 3-1 and several first arc permanent magnets 4-1, the second arc permanent magnet 4-2, screw mandrel arc electrical iron 5-1. The arc angle of each first arc permanent magnet 4-1, second arc permanent magnet 4-2 and arc electrician iron 5-1 is 45 degrees, i.e. 1 / 8 arc, each first circle The inner and outer diameters of arc permanent magnet 4-1, the second arc permanent magnet 4-2 and the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com