Two-stage non-isolated full-bridge grid-connected inverter

A non-isolated, inverter technology, applied in the direction of converting AC power input to DC power output, output power conversion devices, electrical components, etc., can solve problems such as leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

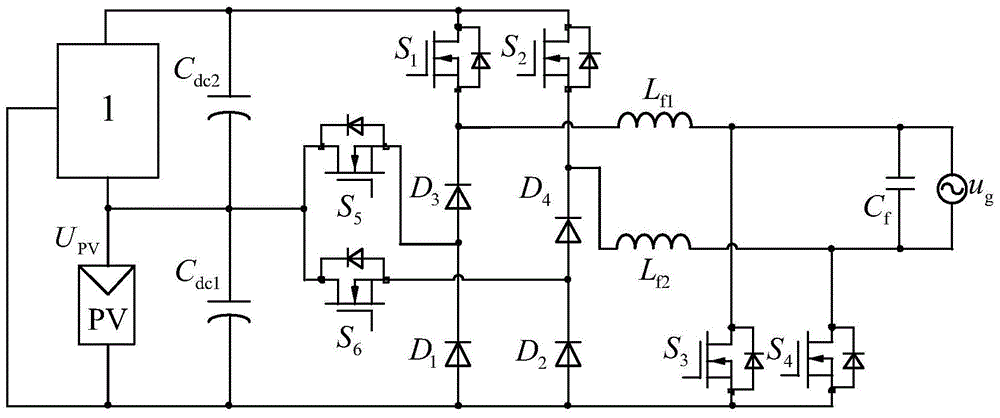

Embodiment 1

[0082] The two-stage non-isolated full-bridge grid-connected inverter described in Embodiment 1 includes six working modes:

[0083] Mode 1: The first power switch tube S 1 , the fourth power switch tube S 4 and the fifth power switch tube S 5 turn on, the other power switch tubes are off, and the incoming current flows through the first power switch tube in turn S 1 , the first filter inductor L f1 , power grid u g , the fourth power switch tube S 4 . third power diode D 3 The voltage stress for the second DC link capacitor C dc2 voltage value.

[0084] Mode 2: The fourth power switch tube S 4 and the fifth power switch tube S 5 turn on, the other power switch tubes are off, and the grid current flows through the fifth power switch tube in turn S 5 , the third power diode D 3 , the first filter inductor L f1 , power grid u g , the fourth power switch tube S 4 . first power diode D 1 The voltage stress for the first DC link capacitor C dc1 v...

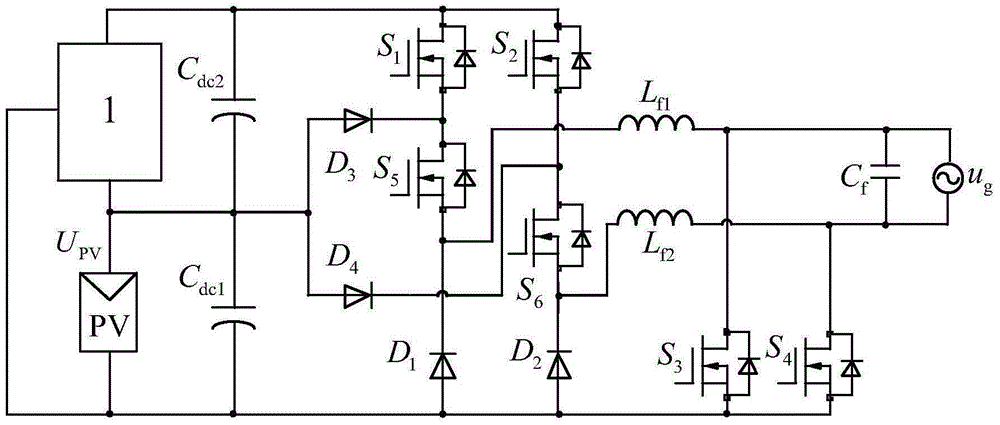

Embodiment 2

[0098] The two-stage non-isolated full-bridge grid-connected inverter described in Embodiment 2 includes six working modes:

[0099] Mode 1: The first power switch tube S 1 , the fourth power switch tube S 4 and the fifth power switch tube S 5 turn on, the other power switch tubes are off, and the incoming current flows through the first power switch tube in turn S 1 , the fifth power switch tube S 5 , the first filter inductor L f1 , power grid u g , the fourth power switch tube S 4 .

[0100] Mode 2: The fourth power switch tube S 4 and the fifth power switch tube S 5 is turned on, the other power switches are turned off, and the incoming current flows through the third power diode in turn D 3 , the fifth power switch tube S 5 , the first filter inductor L f1 , power grid u g , the fourth power switch tube S 4 ; The first power switch tube S 1 The voltage stress for the second DC link capacitor C dc2 voltage value.

[0101] Mode 3: The fourth...

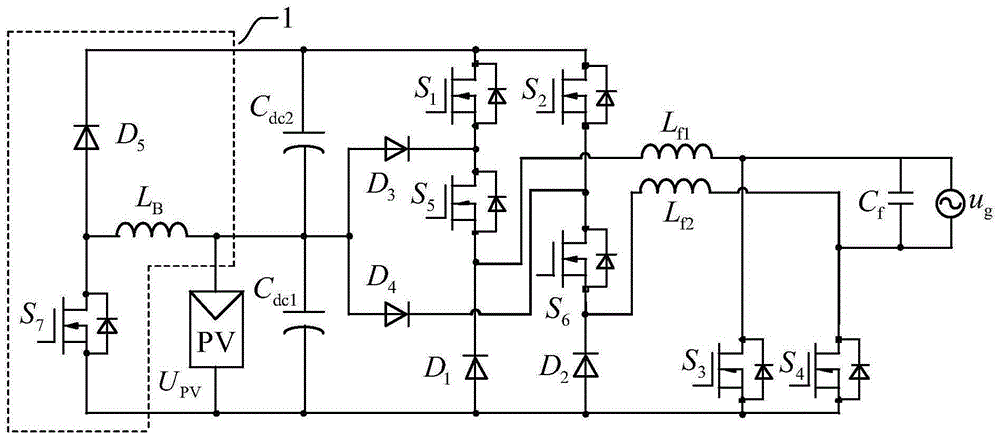

Embodiment 3

[0124] The two-stage non-isolated full-bridge grid-connected inverter described in Embodiment 3 includes six working modes:

[0125] Mode 1: The first power switch tube S 1 , the fourth power switch tube S 4 and the fifth power switch tube S 5 turn on, the other power switch tubes are off, and the grid current flows through the fourth power switch tube in turn S 4 , power grid u g , the first filter inductor L f1 , the first power switch tube S 1 .

[0126] Mode 2: The fourth power switch tube S 4 and the fifth power switch tube S 5 turn on, the other power switch tubes are off, and the grid current flows through the fourth power switch tube in turn S 4 , power grid u g , the first filter inductor L f1 , the third power diode D 3 , the fifth power switch tube S 5 .

[0127] Mode 3: The fourth power switch tube S 4 turn on, the other power switch tubes are off, and the grid current flows through the fourth power switch tube in turn S 4 , power gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com