An industrial color camera color response testing and calibration device and method

A color camera and color response technology, applied in TV, electrical components, image communication, etc., can solve problems such as deviation, and achieve the effect of accurate calibration, high efficiency, and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

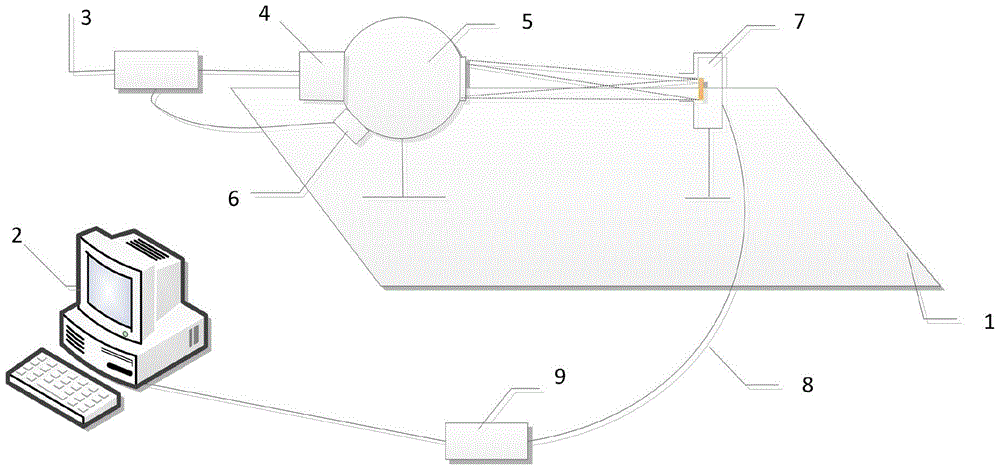

[0017] Such as figure 1 As shown, an industrial color camera color response test and correction device of the present invention, the whole device is placed in a dark room, including a computer 2, an LED drive controller 3, an RGB three-color LED array light source 4, an integrating sphere 5, and a colorimeter 6, the camera to be tested 7, the data transmission cable 8, the data acquisition card 9; the camera to be tested 7 and the integrating sphere 5 are all placed on the optical platform 1, the camera to be tested 7 is connected to the data acquisition card 9 through the data transmission cable 8, and the computer 2. Obtain image data through the data acquisition card 9. The light outlet of the integrating sphere 5 is vertically aligned with the camera 7 to be tested, so that the light is evenly irradiated on the sensor of the camera 7 to be tested; the distance from the light outlet of the integrating sphere 5 to the sensor of the camera 7 to be tested is not less than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com