Grayscale sensor calibration device

A grayscale sensor and calibration device technology, applied in the field of robotics, can solve the problems of low identity of grayscale sensor detection characteristics, huge differences in robot color recognition capabilities, and differences in the same color recognition, so as to improve color recognition accuracy, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

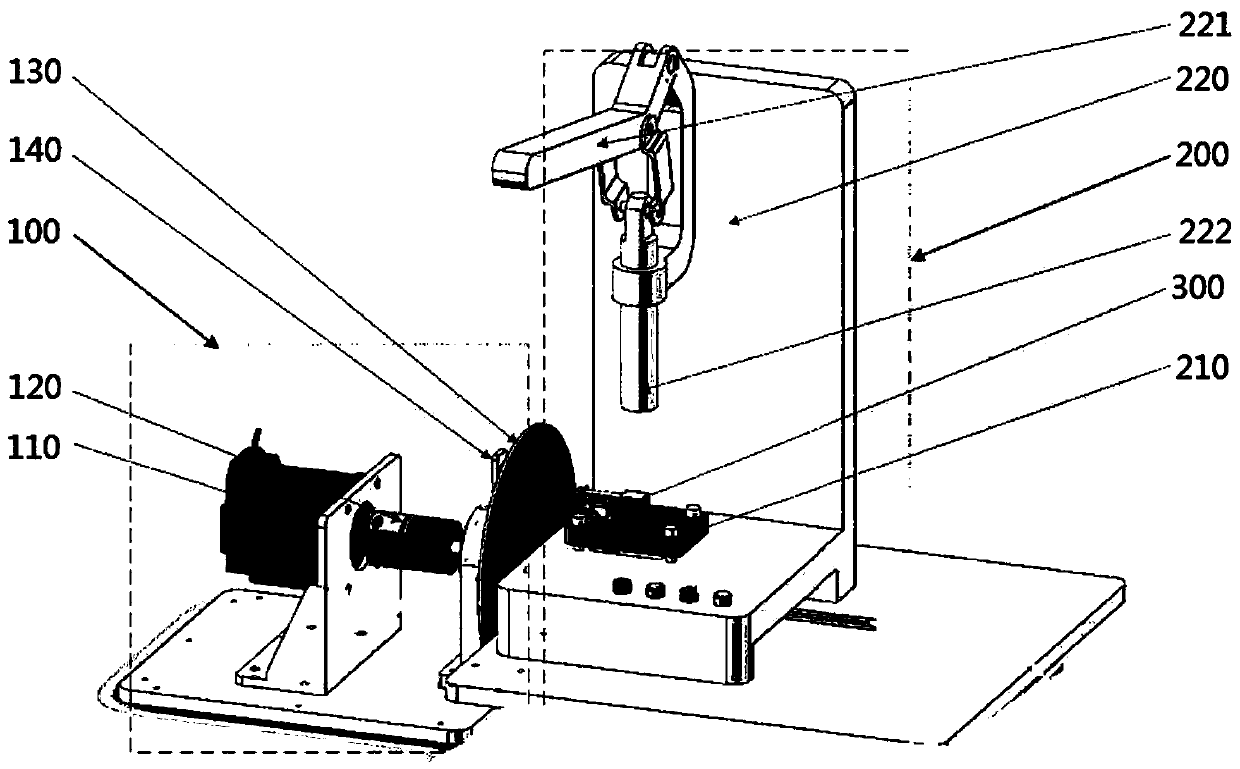

[0015] see figure 1 , a grayscale sensor calibration device, including a color graduation mechanism 100 and a test fixture 200 arranged on one side of the color graduation mechanism 100, the test fixture 200 includes a lifting table for placing a grayscale sensor 300 under test 210, the top of the lifting table 210 is provided with a pressing assembly 220 for pressing down the lifting table 210, and the bottom of the lifting table 210 is provided with a probe that is in contact with the measured grayscale sensor 300, and the lifting table 210 The lower parts around are also connected with springs, and also include a computer for recording test data, and the computer is connected to the probes through wires. In the actual test process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com