Application of shrimp meat offal Zn-chelated peptide

A technology of leftovers and chelated peptides, applied in application, food preparation, food science, etc., can solve the problem of high cost of protein and astaxanthin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] 1) Preparation of protein hydrolyzate from shrimp processing waste: Grind the leftovers (shrimp head and shell) of frozen shrimp processing with a tissue grinder, add phosphate buffer (0.2mol / L, pH7.0) according to the ratio of solid to liquid 1g: 5mL, and put them under ultrasonic power at 47°C. Sonicate at 500W for 90min, then add neutral protease (enzyme activity ≥ 5.0×10 4 U / g), after incubating at 47°C for 2h, the temperature was raised to 95°C and maintained for 10min; the temperature of the solution was lowered to 37°C, the pH was adjusted to 7.8, and trypsin (enzyme activity ≥ 2.5×10 4 U / g) after 3 hours of heat preservation, the temperature rose to 95 ° C and kept for 10 minutes, at 10000 g Centrifuge for 15 minutes to obtain the supernatant, that is, the proteolyzate of shrimp processing leftovers.

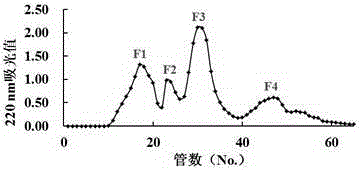

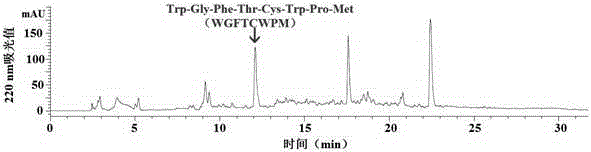

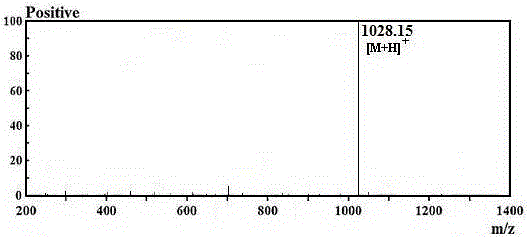

[0024] 2) Preparation of zinc chelating peptide from shrimp processing waste: The prepared enzymatic hydrolyzate is subjected to ultrafiltration treatment wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com