Full-automatic resin diamond dispenser and resin diamond dispensing method

A resin drilling and fully automatic technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of high labor intensity, low efficiency, and large damage to silicone molds, so as to reduce labor intensity and utilize glue. High efficiency and improved dispensing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

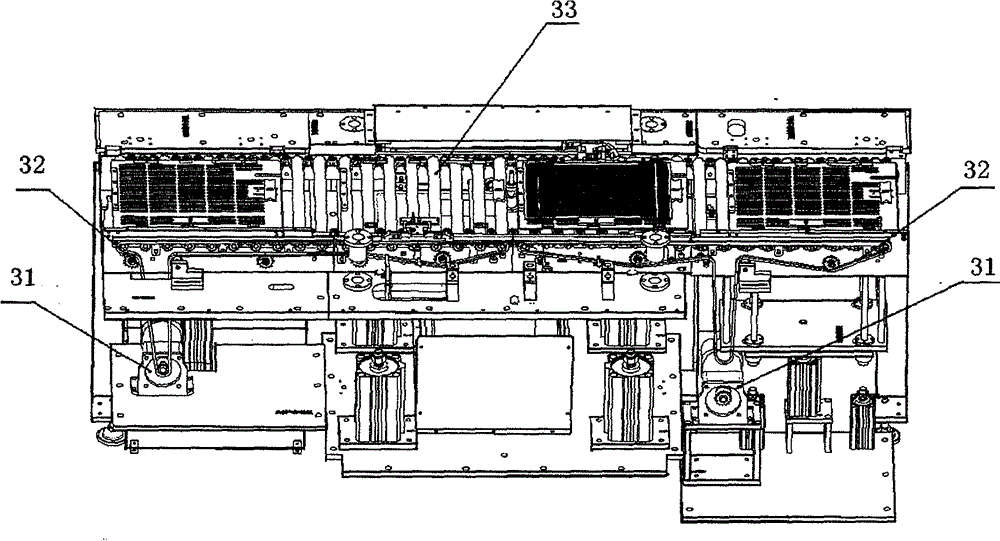

[0031] figure 1 It is a schematic diagram of the structure of the automatic resin drilling and dispensing machine of the present invention, including a machine base 1, a feeding mechanism 2, a transmission mechanism 3, a dispensing mechanism 4 and a discharging mechanism 5, and the feeding mechanism 2, the transmitting mechanism 3 and the discharging mechanism The mechanism 5 is sequentially connected and fixedly installed on the base 1, and the dispensing mechanism 4 is placed above the middle of the transmission mechanism 3;

[0032] like figure 2 , 3 , 4, the dispensing mechanism 4 includes an upper mold 401, a middle mold 402, a lower mold 403, a glue barrel 404, a dispensing mechanism base 405, a dispensing servo motor 406, a guide post 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com