Impurity removal equipment for wearable steel balls

A wear-resistant steel and equipment technology, applied in the field of wear-resistant steel ball impurity removal equipment, can solve problems such as mixing and difficult removal, and achieve the effect of cleaning impurities cleanly, with high degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

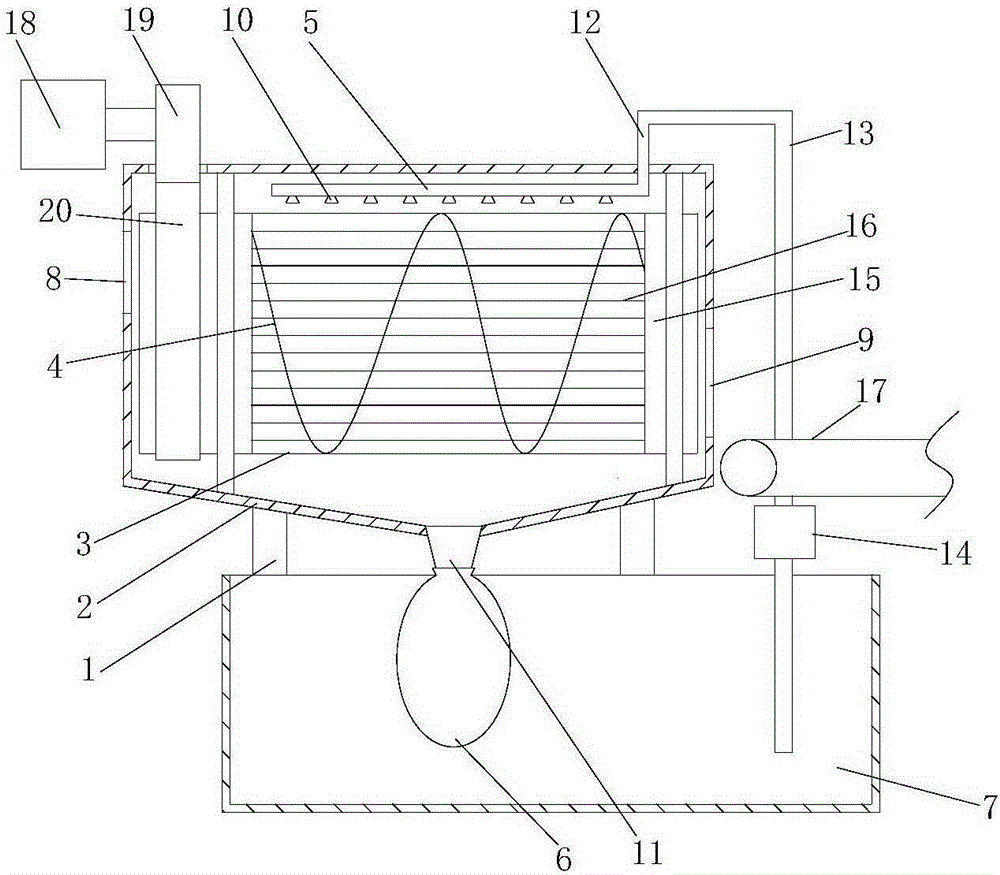

[0019] refer to figure 1 , a wear-resistant steel ball impurity removal equipment proposed by the present invention, including a frame 1, an outer box 2, an inner drum 3, a screw pusher 4, a spray pipe 5, an impurity collection bag 6 and a spray liquid pool 7.

[0020] The outer box body 2 is fixed on the frame 1.

[0021] The inner drum 3 is rollingly supported in the outer box body 2, and is driven to rotate by the inner drum 3. The inner drum 3 has a hollow structure and is provided with a screw propeller 4 inside. The two ends of the inner drum 3 are open. Specifically, the inner drum 3 includes two Two end cylinders 16, and a circular tube 16 welded between the two cylinders 16 and forming a cylindrical structure, the structure is simple, the hollow area is effectively increased, impurities are more easily discharged from the inner drum 3, and the spraying is more comprehensive , Increase the effective spray area, speed up the speed of impurity removal, and improve the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com