Machining die for steel strip open-type lock catch for package

A technology for processing molds and packaging, which is applied in the field of cold-rolled steel strip packaging lock processing, can solve the problems of wasting manpower and material resources, long production cycle, and large floor space, etc., achieves convenient loading and unloading, reduces equipment investment, and improves productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

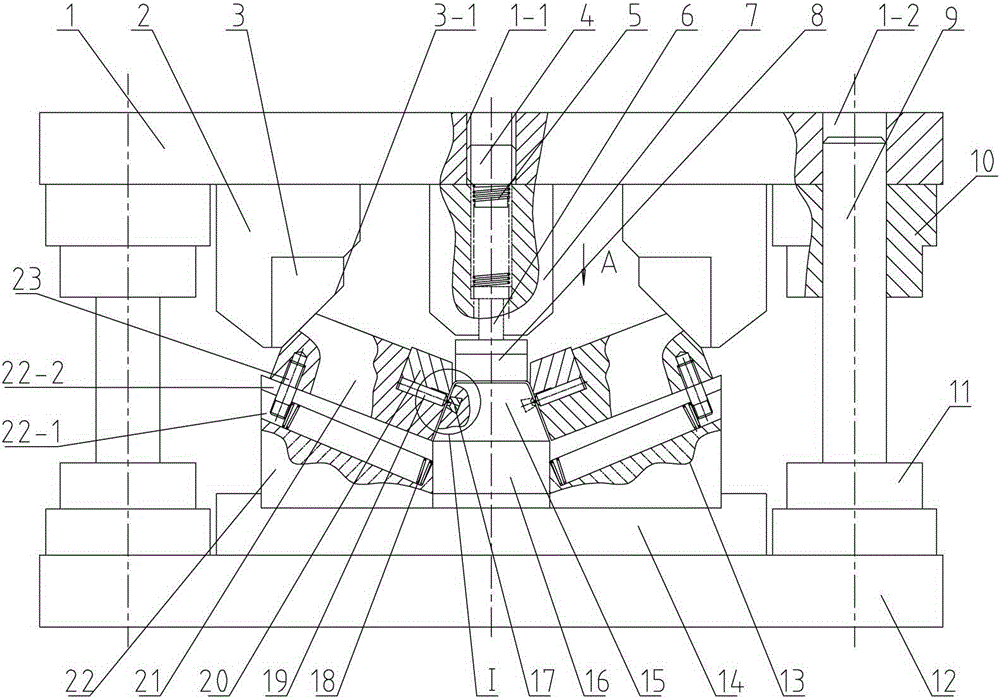

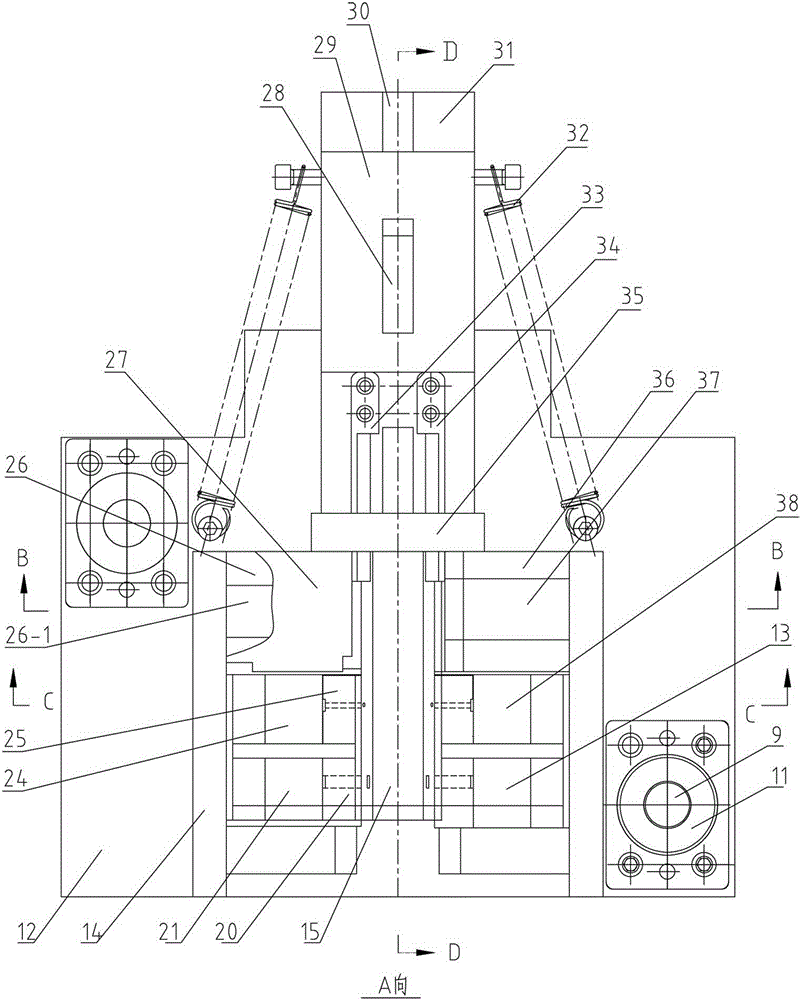

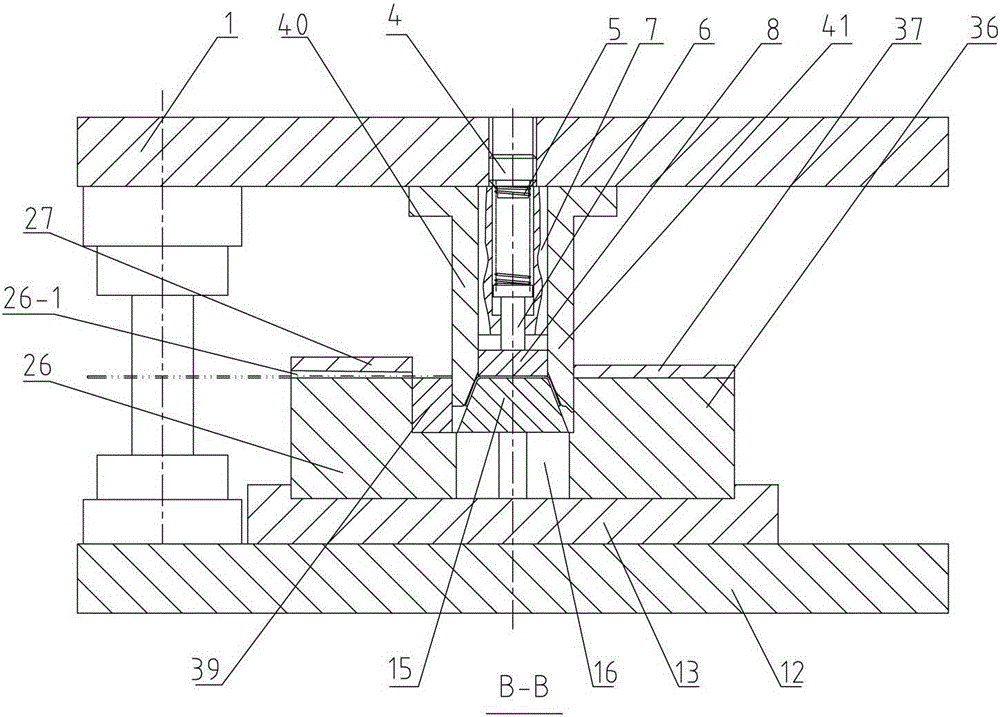

[0028] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 , 2 , Shown in 3, a kind of processing mold of steel band open type lock buckle for packaging of the present invention comprises upper mold assembly, lower mold assembly, the pushing material that is connected with this upper mold assembly, lower mold assembly respectively device and two upper mold lifting guide column devices, the processing mold of this open lock should be used in conjunction with the punching machine, the upper mold assembly is fixed on the lifting platform on the punching machine, and the lower mold assembly is fixed on the fixing plate on the punching machine get off the deck,

[0030] The upper mold assembly consists of an upper template 1, a lower die base 7 fixedly connected to the upper template 1, a punching and shearing die 40 fixedly connected to the left side of the lower die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com