Color filament yarn spinning device of wool-like fabric and filament yarn processing method of fabric

A processing method and technology of filament yarn, applied in the direction of yarn, textile and papermaking, can solve the problems of damage to wool, reduced spinning efficiency, etc., and achieve the effect of reducing production cost, shortening production process and cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

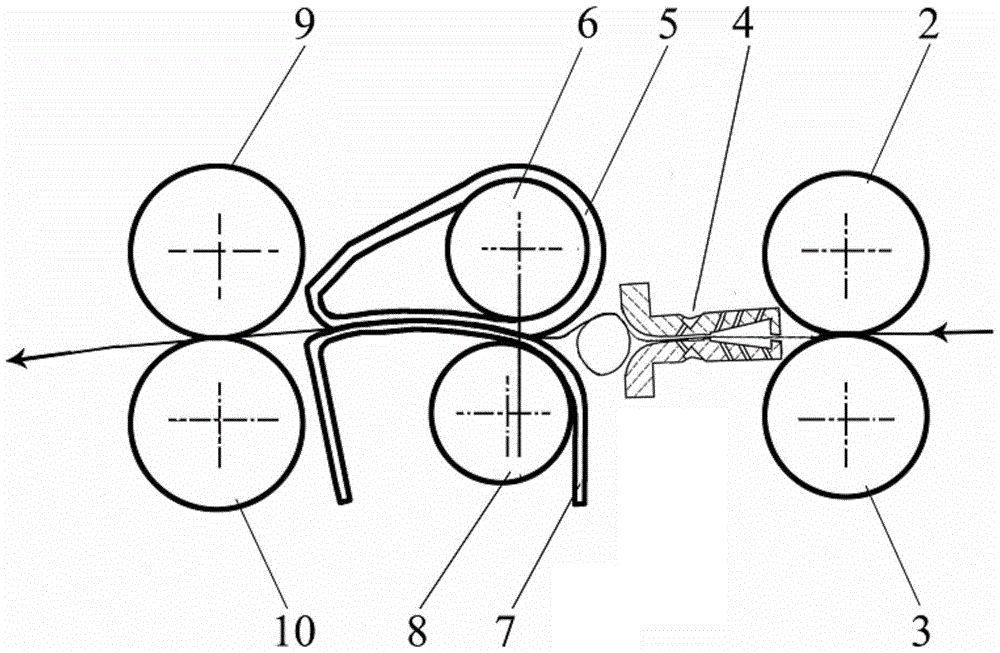

Embodiment 1

[0040] The ratio of red and black filaments that make up the multifilament is 1:4. The target yarn is reddish fine black wool yarn, which is used on thin wool fabrics.

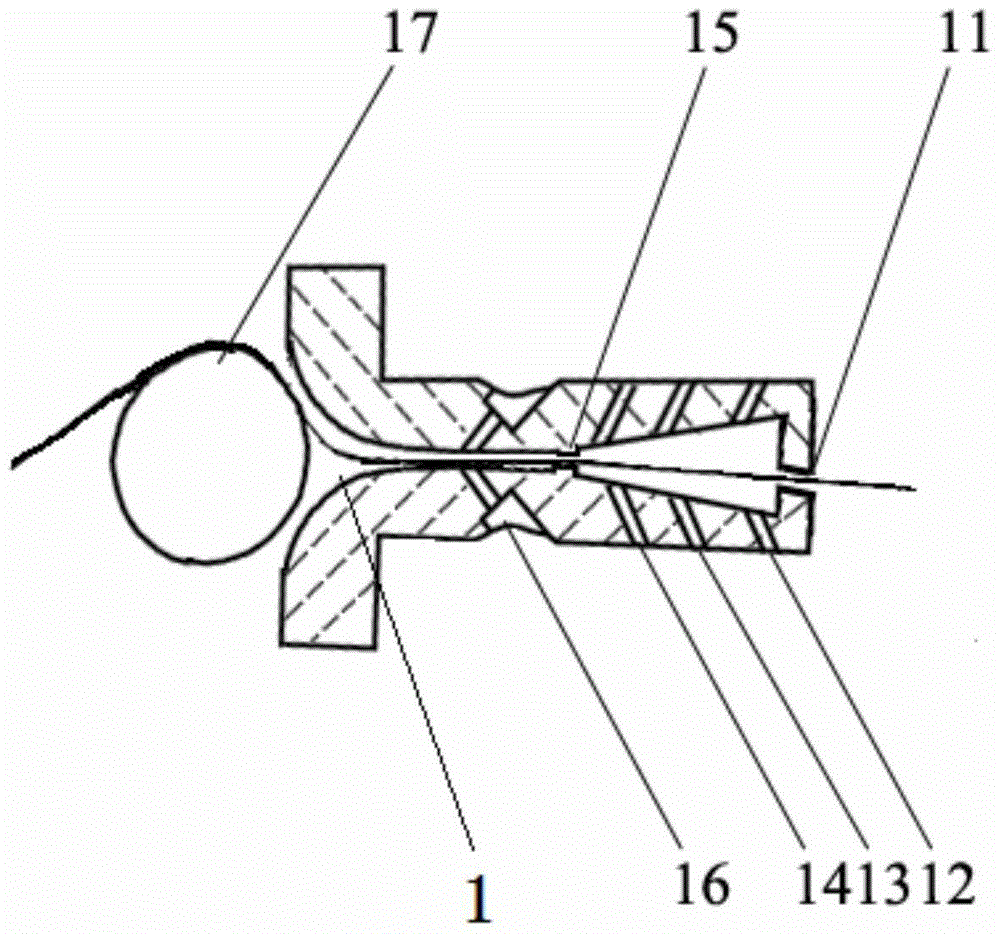

[0041] The middle and rear rollers are overfeed at an overfeed ratio of 1.20%. After the yarn body enters the fiber texturizing device, three sets of high-temperature water vapor input ports are symmetrically distributed up and down the cavity, and the output air containing water vapor gradually rises, and the moisture supply is 0.8, 0.9, 1.0L / h respectively; the yarn body is separated by a partition Finally, it is blown away by the high-pressure air of 0.64Mpa from the high-pressure air inlet, and the filament is deformed after colliding with the ball, and the length of the ball extending into the outlet is controlled at 3.5mm.

[0042] In the rear drafting area: the diameter of the two rollers is 25mm, and the horizontal center distance is 170mm. The pressure of the rear roller is 16daN / double spindle, and...

Embodiment 2

[0046] The ratio of red, blue and black filaments that make up the multifilament is 4:4:1. The target yarn is purple fine black wool yarn, which is applied on wool fabric.

[0047] The middle and rear rollers are overfeed with an overfeed ratio of 1.35%. After the yarn body enters the fiber texturizing device, three sets of high-temperature water vapor input ports are symmetrically distributed up and down the cavity, and the output air containing water vapor gradually rises, and the moisture supply is respectively 0.9, 1.0, and 1.1L / h; the yarn body is separated by a partition Finally, it is blown away by the 0.66Mpa high-pressure air from the high-pressure air inlet, and the filament is deformed after colliding with the ball, and the length of the ball extending into the outlet is controlled at 4.0mm.

[0048] The front drafting area is composed of the middle roller and its attached rubber ring, and the front roller. The diameter of the front roller is 25mm, the pressurizat...

Embodiment 3

[0052] The ratio of red, silver and black filaments that make up the multifilament is 4:1:15. The target yarn is thick extra-black fancy wool yarn with a reddish surface and a metallic silver luster, which is used on thicker wool fabrics.

[0053] The middle and rear rollers are overfeed at an overfeed ratio of 1.50%. After the yarn body enters the fiber texturizing device, three sets of high-temperature water vapor input ports are symmetrically distributed up and down the cavity, and the output air containing water vapor gradually rises, and the moisture supply is 1.0, 1.1, and 1.2L / h respectively; the yarn body is separated by a partition Finally, it is blown away by the 0.68Mpa high-pressure air from the high-pressure air inlet, and the filament is deformed after colliding with the ball, and the length of the ball extending into the outlet is controlled at 4.5mm.

[0054] In the rear drafting area: the diameter of the two rollers is 25mm, and the horizontal center distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap