Knitting method for doping fabric with strip-shaped metal fiber wrap set

A technology of metal fibers and mixed strips, applied in the fields of textile machinery and weaving, can solve the problems of inability to implement the whole-width warping process, inability to use, and large tension changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

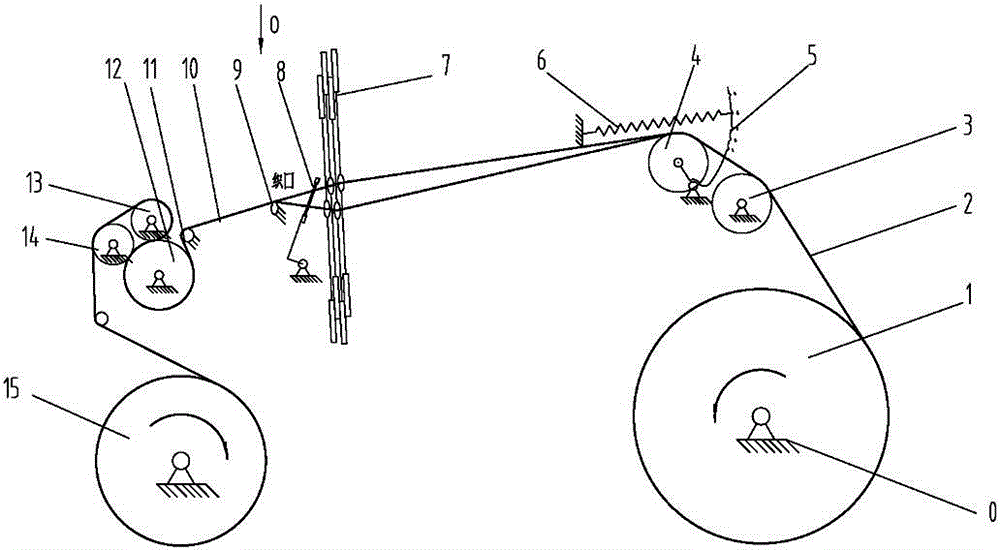

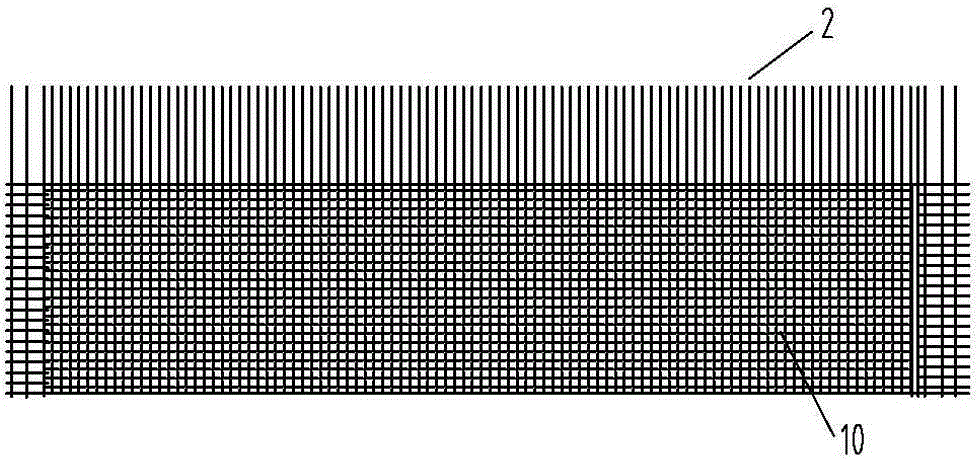

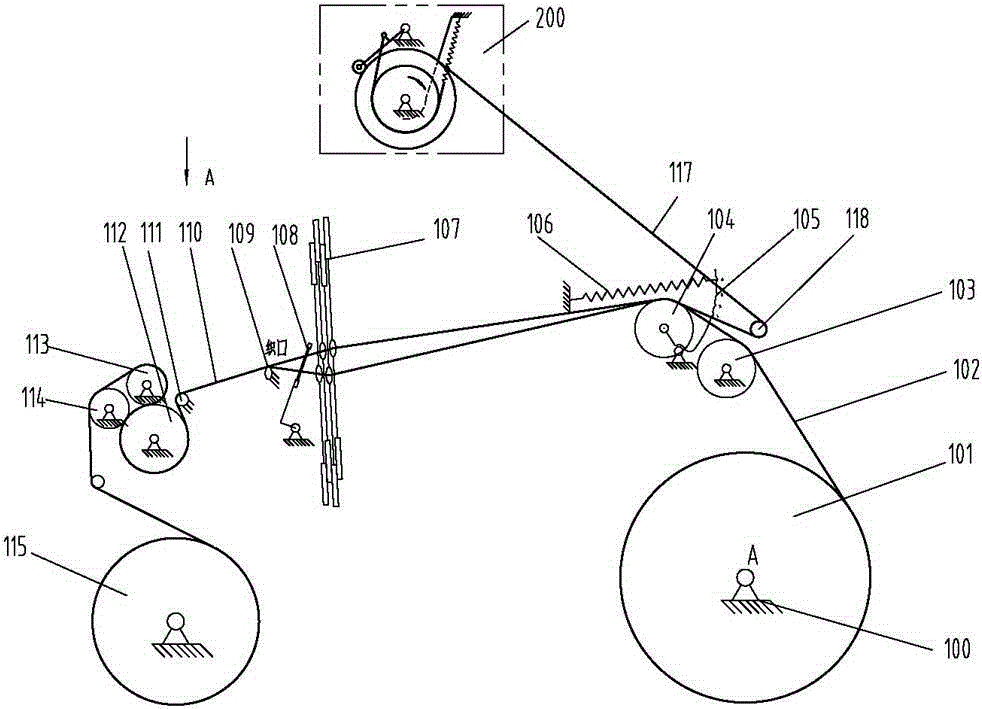

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings: Warp yarn trend when warp yarn storage and weaving described in the present invention image 3 , 4 As shown, the trend and tension control of one group of warp yarns 102 are consistent with the prior art.

[0028] The warp beam 101 is connected with the frame 100 through a bearing, and is driven by the warp let-off drive system of the loom; the fixed back rest 103 is connected with the frame 100 through a bearing; The other end of 106 is fixedly connected with frame 100. The warp yarn 102 is stored on the warp beam 101. When weaving, it is withdrawn from the warp beam 101, and reaches the movable back beam 104 through the fixed back rest 103. Another group of warp yarns 117 is withdrawn from the independent bobbin system 200, and then reaches the movable back beam 104 of the loom through the steering eyelet 118, mixes with the first group of warp yarns 102, interweav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com