A kind of elastic thick imitation marble coating and its brushing process

A technology of imitating marble and marble, which is applied in the field of elastic thick imitation marble coating and its brushing process, can solve the problems of poor crack resistance, low simulation degree, easy cracking, etc., so as to avoid coating cracking, improve simulation degree, The effect of long-lasting coating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

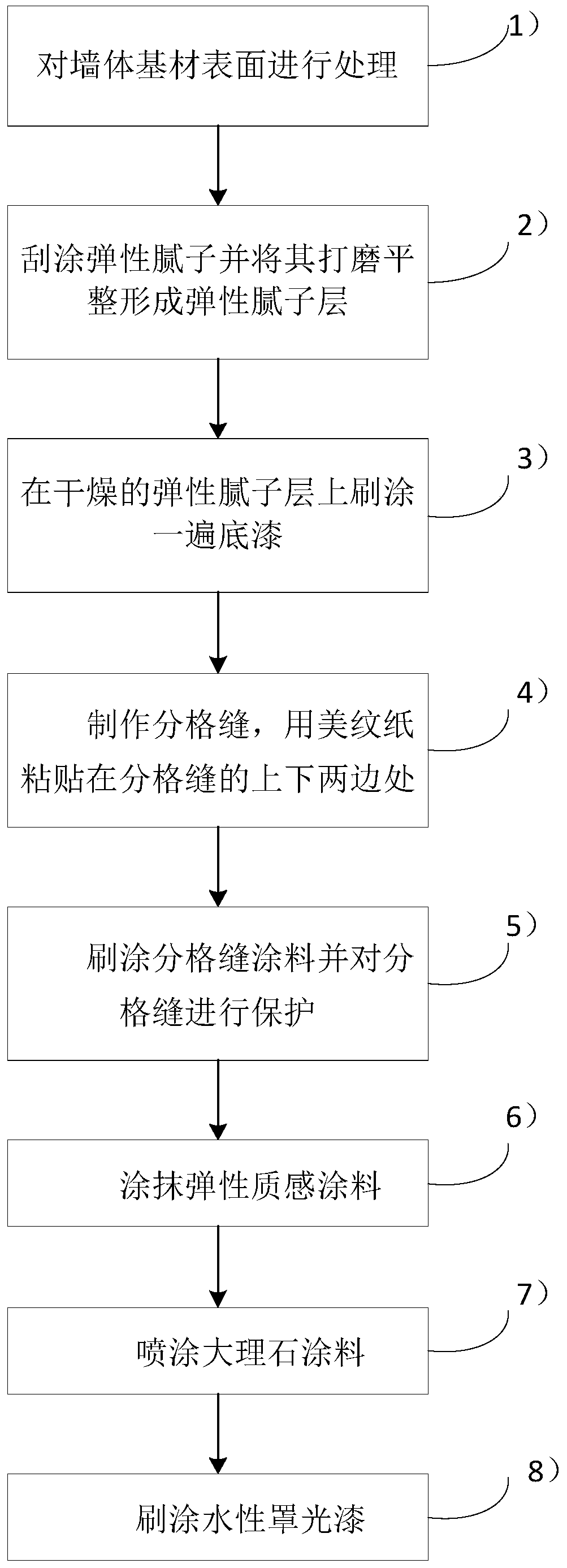

[0031] In order to facilitate those skilled in the art to understand the technical solutions and beneficial effects of the present invention, specific implementation methods are described below in conjunction with the accompanying drawings.

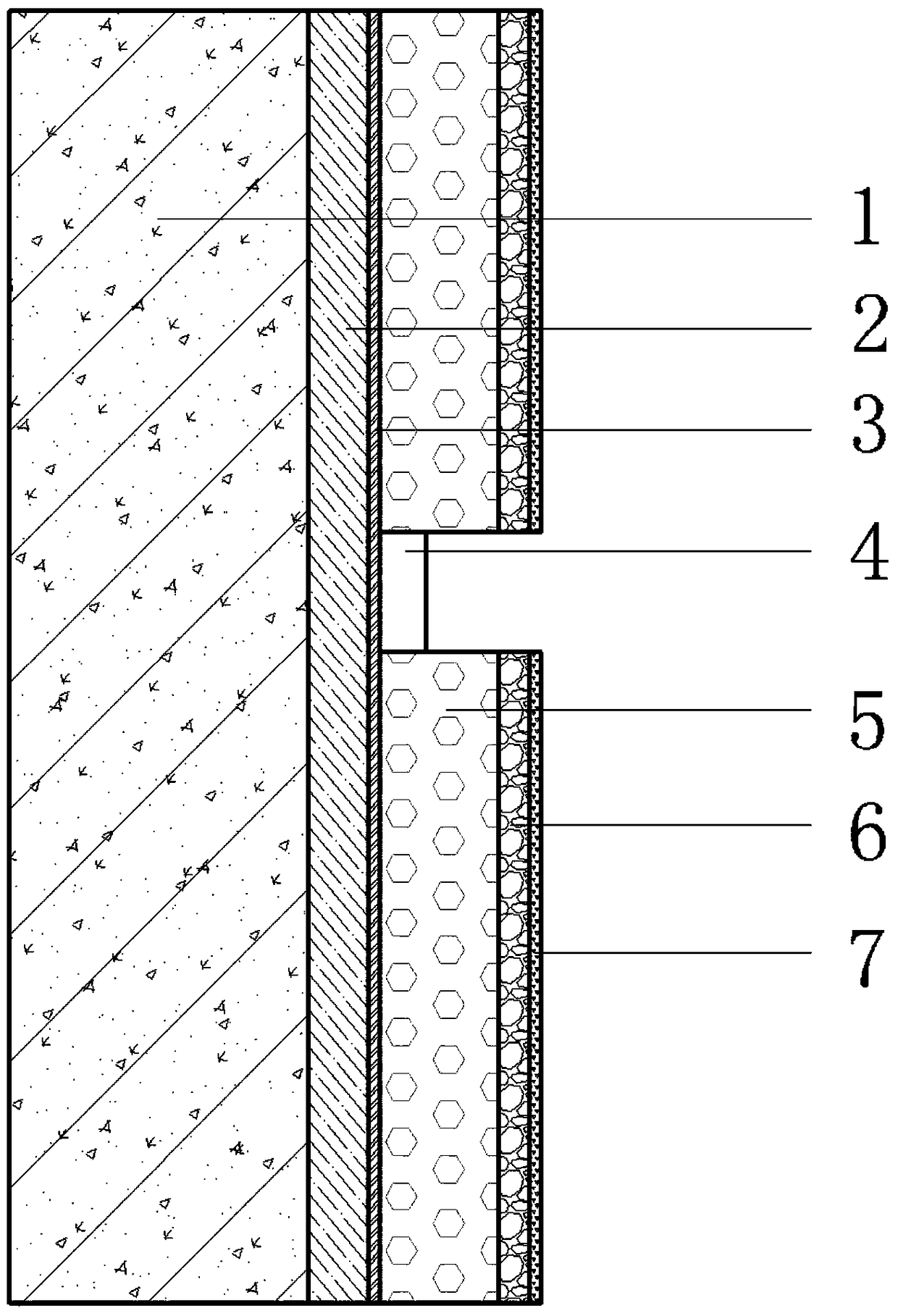

[0032] Such as figure 1 Shown, it is the structure schematic diagram of the elastic thick imitation marble coating in the present invention, as can be seen from the figure, this marble coating is attached on the wall body substrate 1, comprises the grid seam area, and the grid seam area divides all The elastic thick imitation marble coating is divided into multiple coating areas;

[0033] From the wall substrate 1 outwards, the grid joint area includes: elastic putty layer 2, primer layer 3 and grid joint paint layer 4;

[0034] The separated coating area includes: elastic putty layer 2, primer layer 3, elastic texture paint layer 5, liquid marble layer 6 and water-based finish paint layer 7 from the wall substrate 1 in order;

[0035] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com