Coring device for oil sandy core

A technology for coring device and oil sandstone, which is applied in the direction of extracting undisturbed cores, earthwork drilling, etc., can solve the problems of inability to meet the requirements of batch coring, shortening the coring time, and high labor costs, and achieves high coring efficiency and low cost. , the effect of improving the efficiency of coring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

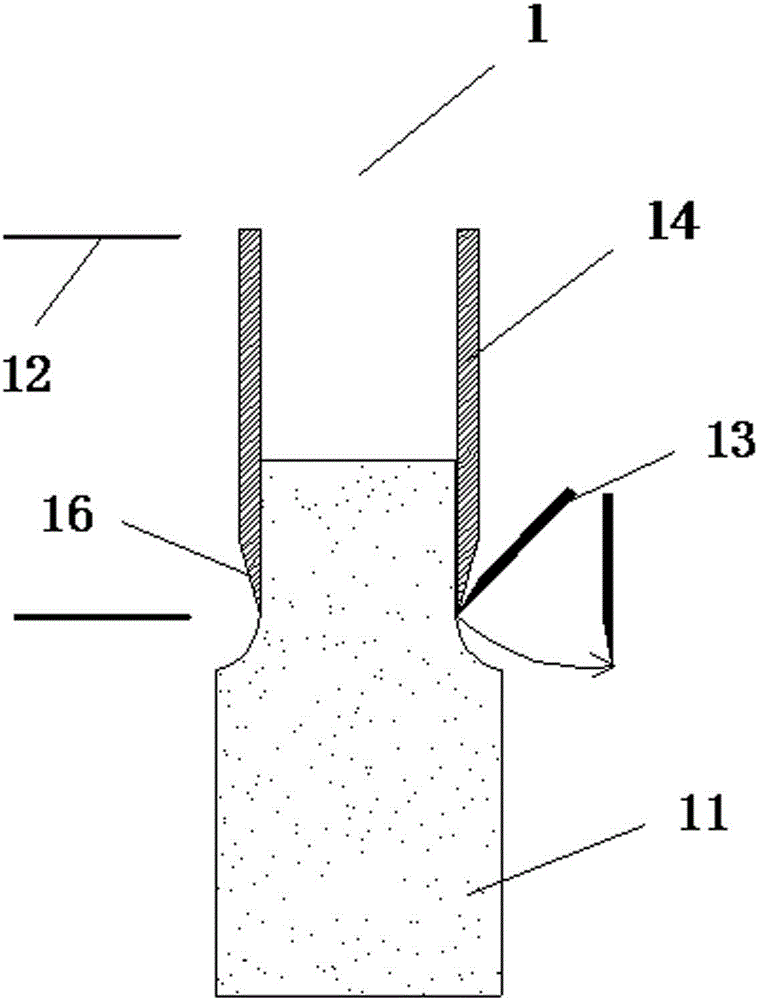

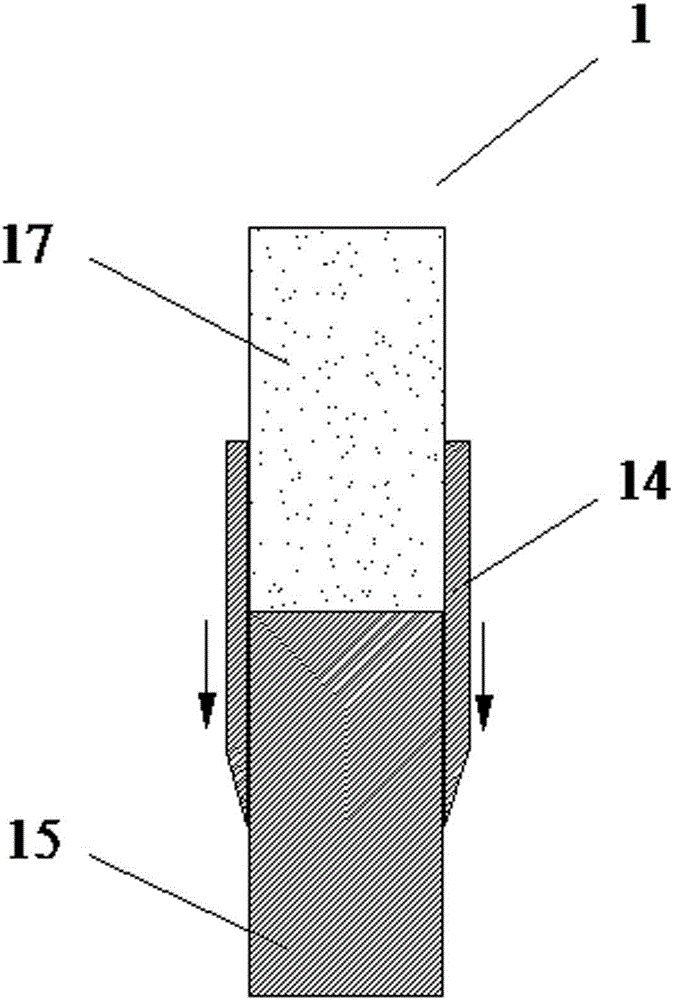

[0069] Such as figure 1 and figure 2 As shown, according to an embodiment of the coring device 1 of the oil sand core of the present invention, it includes an in-situ rock core 11, a horizontal cutter 12 and a vertical cutter 13, and also includes a coring barrel 14 and a coring column 15 , one end of the core cylinder is in the shape of a blade 16, the core cylinder 14 and the vertical cutter 13 work together to cut the in-situ rock core 11, the diameter of the core cylinder 15 is the same as that of the oil The sandstone cores 17 are of equal diameter.

[0070] The core barrel is made of stainless steel. The overall height of the core barrel is 76mm, the outer diameter is 43.5mm, the inner diameter is 38.5mm, and the wall thickness is 2.5mm. One end of the core barrel is blade-shaped and the height is 15mm. The core column is made of aluminum alloy, the height of the core column is 76mm, and the diameter is 38mm.

[0071] Such as Figure 10 As shown, the coring method o...

Embodiment 2

[0079] According to another embodiment of the coring device for oil sand cores of the present invention, its structure, coring principle and coring method are all the same as in Embodiment 1, the difference is: the core cylinder is made of aluminum alloy material, The overall height of the core barrel is 50mm, the outer diameter is 30.5mm, the inner diameter is 25.5mm, and the wall thickness is 2.5mm. One end of the core barrel is blade-shaped and the height is 10mm. The core column is made of aluminum alloy material, the height of the core column is 50mm, and the diameter is 25mm.

Embodiment 3

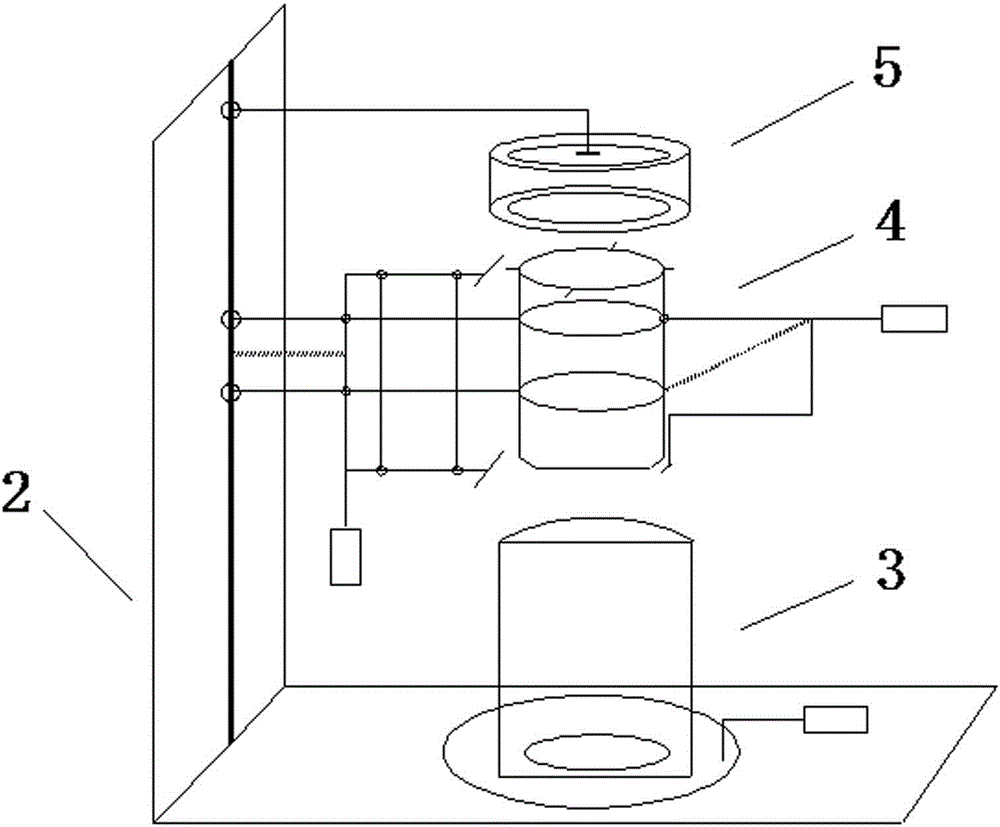

[0081] Such as image 3 As shown, according to another embodiment of the coring device for oil sand cores of the present invention, its structure and coring principle are the same as those in Embodiment 1, except that it also includes a support assembly 2, an in-situ core assembly 3, a The core barrel assembly 4 and the weight assembly 5.

[0082] Such as Figure 4 As shown, the support assembly 2 includes a workbench 21 , a support plate 22 , a guide rail 23 and a slip ring 24 , and the support plate 22 is vertically connected to the workbench 21 . In the process of making oil sand core, the workbench can be used to support the in-situ core assembly, core barrel assembly and weight assembly; the slip ring has a certain length, and the slip ring can move freely on the vertical guide rail during normal operation; The guide rail 23 is arranged on the support plate 22, and is vertically connected between the guide rail 23 and the workbench 21; the slip ring 24 is arranged on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com