Double-throttling-nozzle downhole throttling device

A double throttle and throttle technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

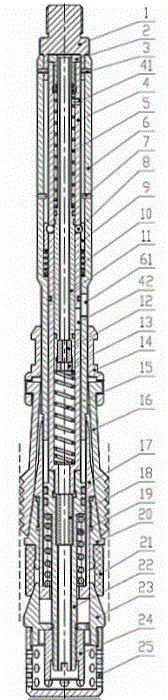

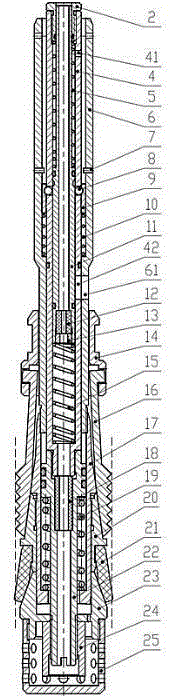

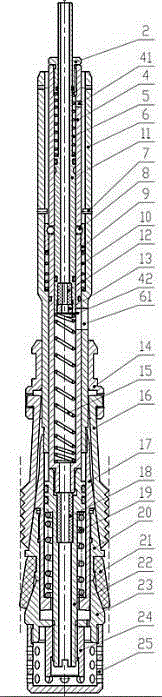

[0013] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a downhole choke with double choke nozzles of the present invention is composed of a delivery head 1, an end cover 2, a delivery shear pin 3, an upper central tube 4, a spring a5, an outer cylinder 6, a limit pin 7, a steel ball 8. Collar 9, spring b10, mandrel 11, upper throttle nozzle 12, pressure cap 13, fishing head 14, spring c15, slips 16, lower cylinder 17, lower throttle nozzle 18, spring d19, upper cone Tube 20, sealing rubber ring 21, lower center tube 22, lower cone tube 23, fastening nut 24 and sand control cover 25 constitute; Its structural feature is: delivery head 1 is connected with the threaded connection of upper delivery pipeline, delivery head 1 bottom and The upper part of the outer cylinder 6 is connected with the shear pin 3; the upper part of the mandrel 11 is set as a screw, the middle part of the outer circle of the mandrel 11 is provided with a step, the bottom of the step is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com