Multi-unit turbine steam flow real-time distributing method based on main pipe scheme

A steam flow and steam turbine technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of not being able to obtain the steam flow of the steam turbine, not being able to reflect the performance difference of the steam turbine, and being unfavorable for energy-saving operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] 1) Collect the historical steady-state data of the operating conditions of a single steam turbine in the parent control unit

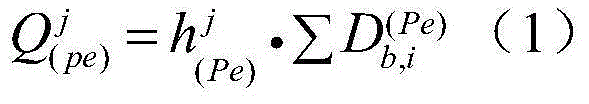

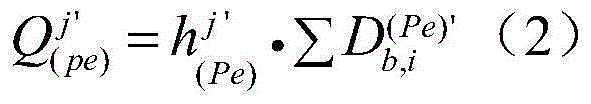

[0033] Suppose there are a total of n steam turbines in the power plant, inquire the working conditions of the jth steam turbine (assuming that there are n steam turbines in total in the power plant, 1≤j≤n) in the information system of the power plant, and calculate its historical steady state (i.e. excluding start-up and shutdown loads, etc. The working condition with a large change rate) the operating data is exported, and the load P in the historical steady-state operating data is extracted e j And the corresponding steam pressure of the main pipe under this load steam temperature steam flow data. This is the basis for establishing the calculation model of the relationship between the power of the steam turbine and the heat flow of the inlet steam;

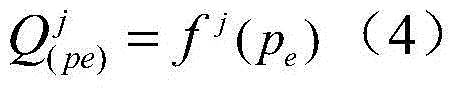

[0034] 2) Establish the calculation model of the relationship between the power of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com