Electric sliding discal valve type gas flow regulating device for solid rocket propellant ramjet

A gas flow regulation and ramjet technology, which is applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of difficult to achieve precise control, inability to achieve precise control, and large experimental system volume. The effect of channel deposition blockage, low cost and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

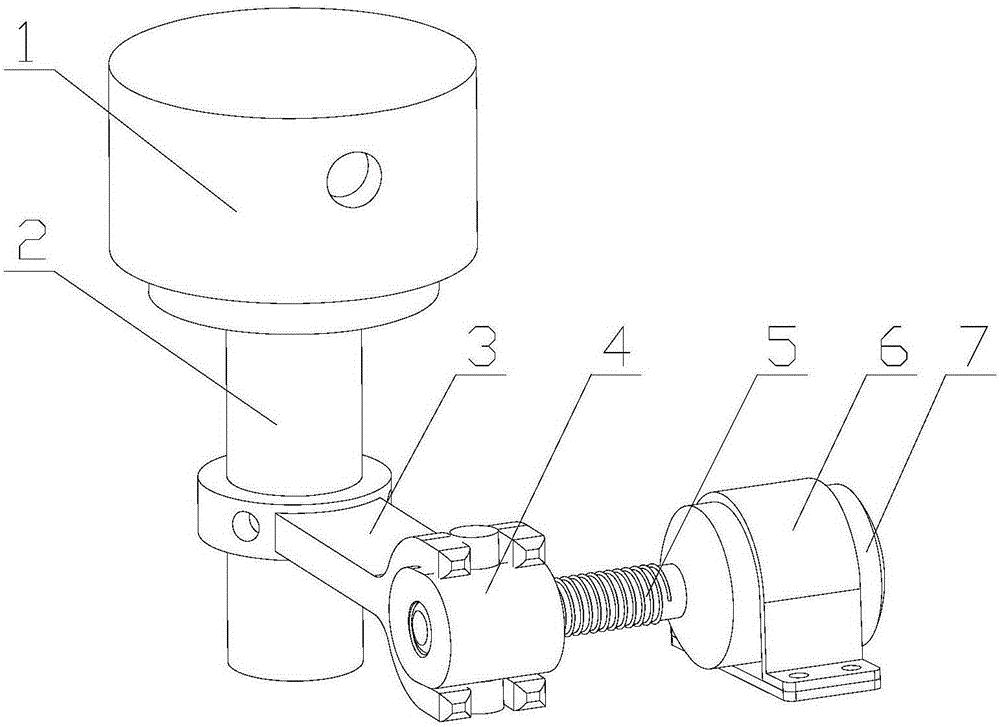

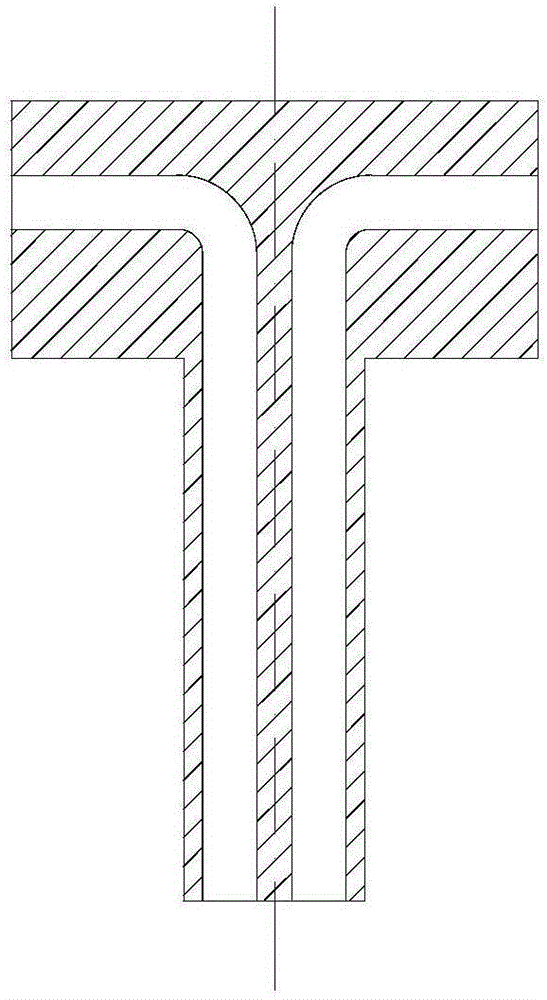

[0034] An electric sliding disc valve type solid rocket ramjet gas flow regulating device, comprising: a sleeve 1 with a cylindrical inner cavity, a valve core 2 that extends into the inner cavity of the sleeve 1 and rotates with the sleeve 1 to provide a rotational output The drive motor 7, the drive screw 5 connected to the output end of the drive motor 7, the drive nut 4 that forms a lead screw structure with the drive screw 5, and the drive lever 3 that converts the linear motion of the drive nut 4 into the rotary motion of the spool 2 Wherein, one end of the transmission lever 3 has a spool fixing hole, and the spool 2 is fixed in the spool fixing hole, and the other end of the transmission lever 3 and the transmission nut 4 rotate in the axial direction of the transmission nut 4 and the transmission nut 4 can Move along the axial direction of the transmission lever 3; there are two symmetrical and disconnected gas passages inside the valve core 2, and the gas passage exte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap