Road material washing test device adopting electromagnetic driving

A technology of scour test and road material, which is applied in the direction of testing wear resistance, etc., can solve problems that affect the life and use of the road surface, subsidence, road area mud, etc., and achieve the effect of being suitable for popularization, improving scour efficiency, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The water damage faced by road materials in the actual application process is mainly reflected in the erosion of the surface of the material by the water flow and the peeling off of the surface of the material due to the pumping action generated during the movement of the water flow. However, none of the existing test equipment can simulate the above process objectively and effectively. The idea of the present invention is to provide a test device for simulating the effects of scouring, pumping and the like by controlling the movement of water flow.

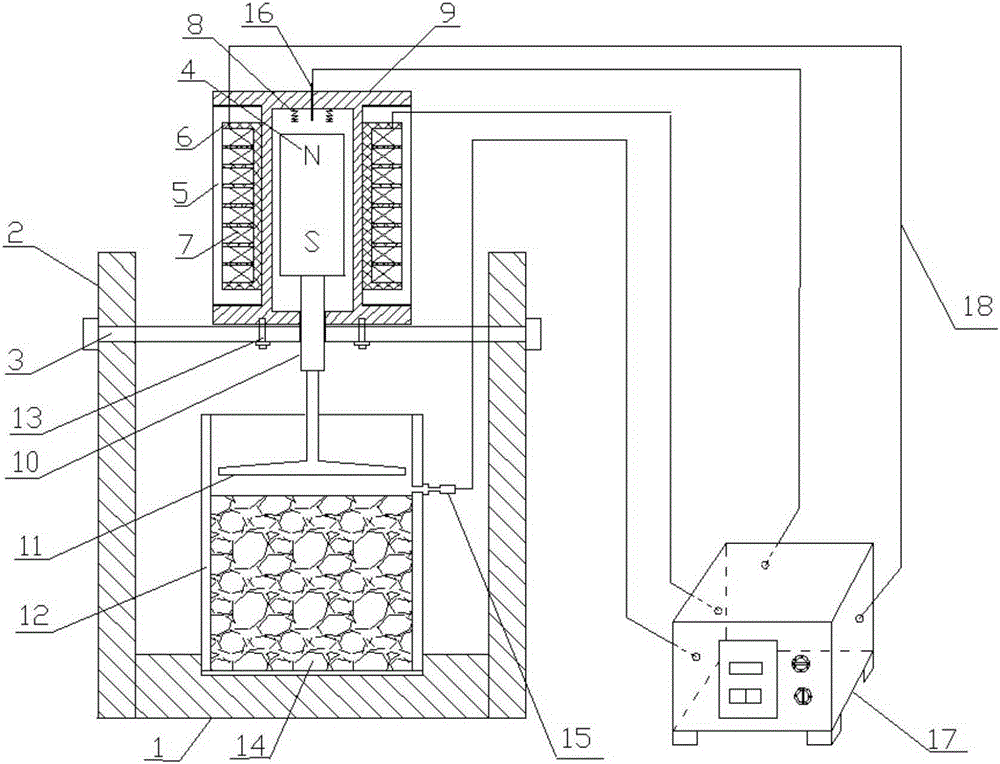

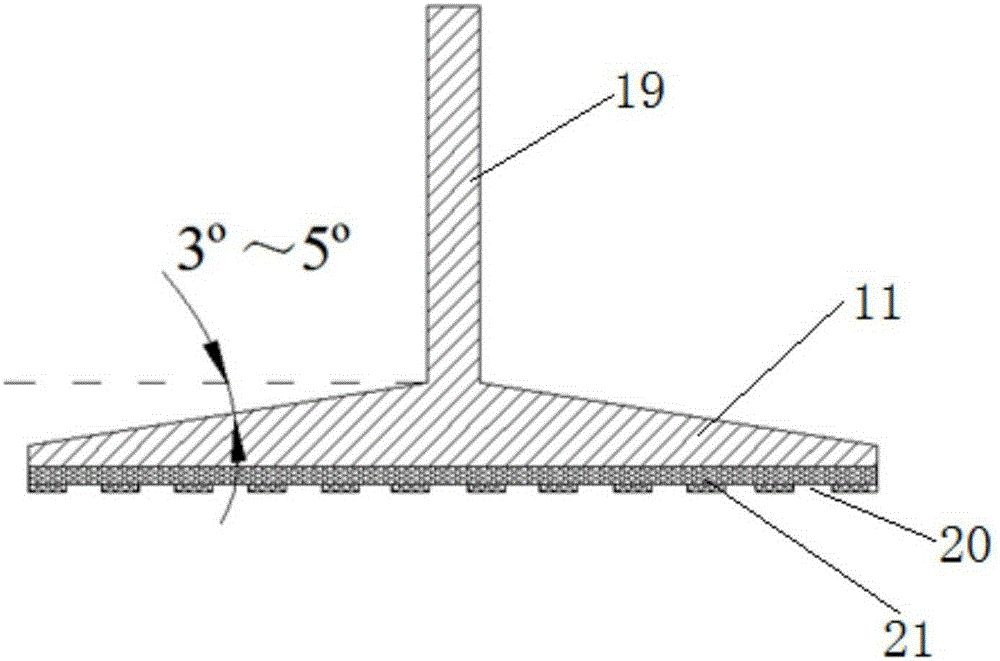

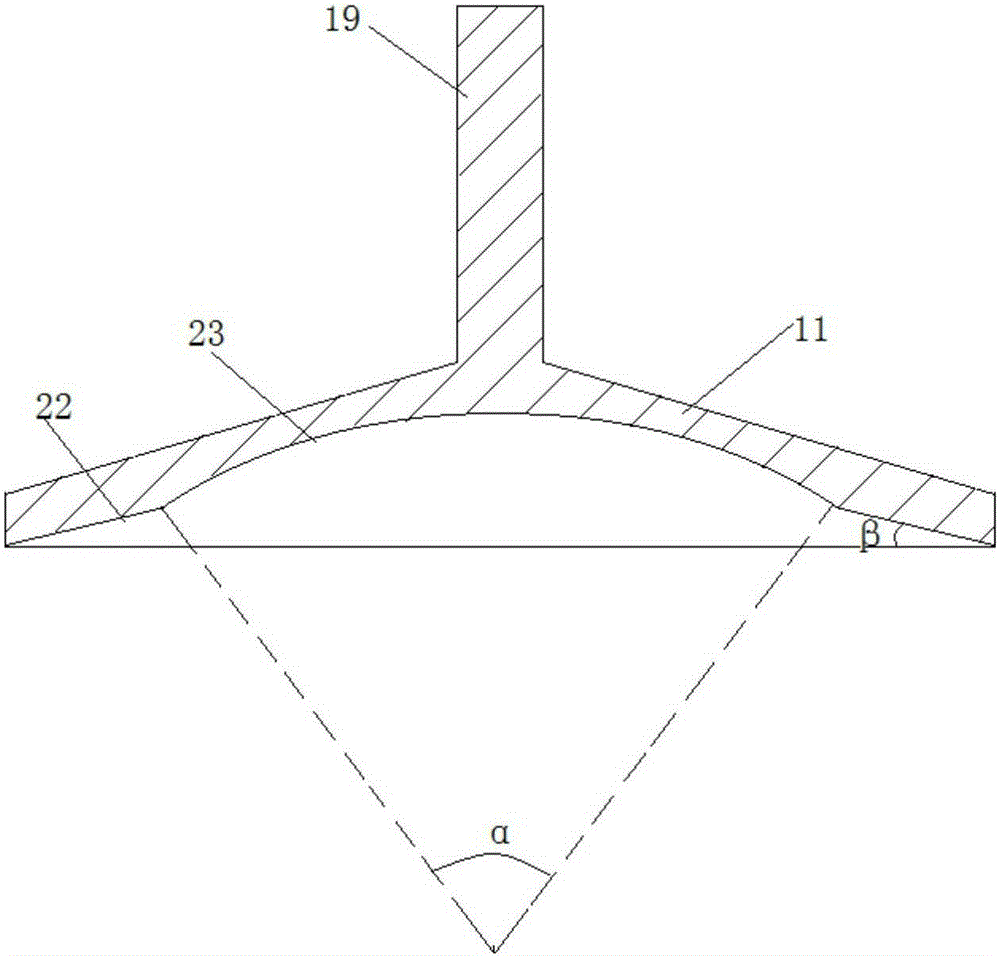

[0026] like figure 1 As shown, an electromagnetically driven road material scouring test device includes a scouring bucket 12, a test piece 14 is placed in the scouring bucket 12, and water is filled in the scouring bucket 12, and the water surface exceeds the top surface of the test piece 14; A scour plate 11 that can move close to or away from the top surface of the test piece 14 is arranged above the top of the test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com