Through type cophase traction power supply system traction network fault interval traveling wave positioning method

A technology of traction power supply system and fault interval, applied in the direction of fault location, etc., can solve problems such as inaccurate positioning and influence of traveling waves, achieve the effects of reducing power outage time, strong ability to withstand transition resistance, and improving power supply reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

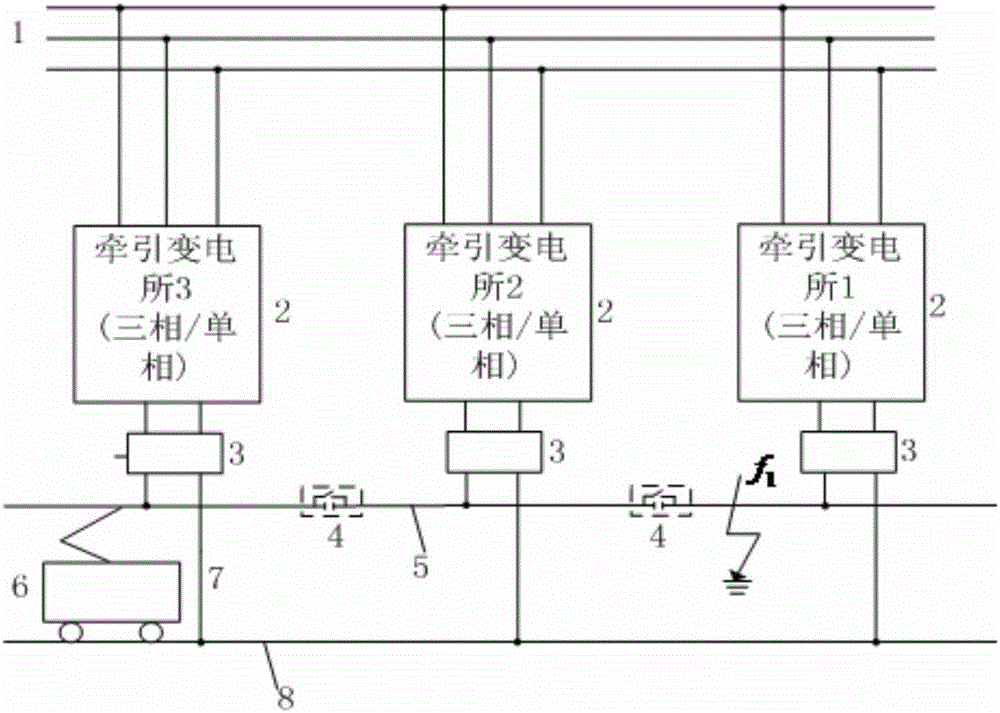

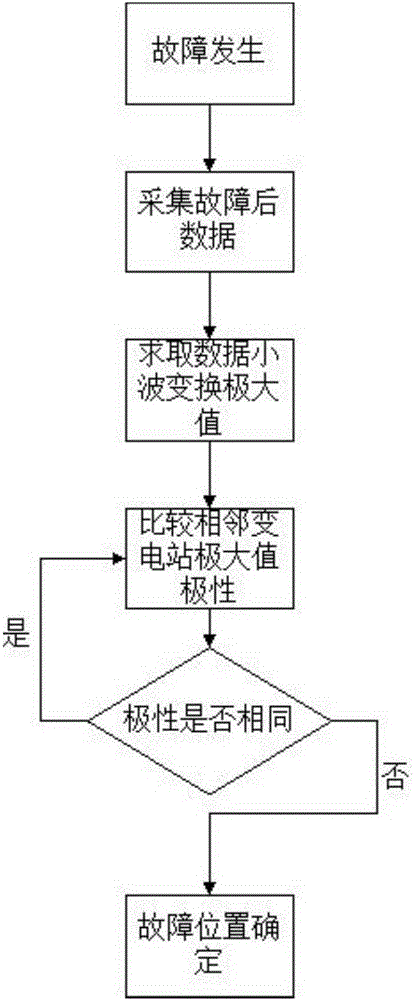

[0034] Embodiment 1: as Figure 1-6 As shown, a traveling wave location method for the fault zone of the traction network of a through-type in-phase traction power supply system, the specific steps of the method are:

[0035] A. After a fault occurs on the traction network of the through-type same-phase traction power supply system, the data acquisition devices of each traction substation collect the current within the 10ms time window after the fault occurs;

[0036] B. Obtain the maximum value of the wavelet transform modulus of the fault current signal at the exit of each traction substation;

[0037] C. Compare the modulus maximum polarity of the current traveling wave signal at each outlet;

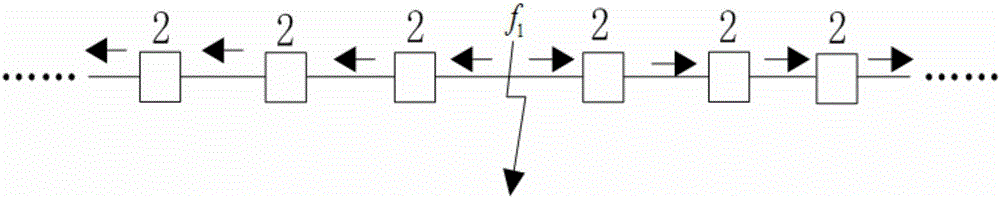

[0038] If the polarity of the fault current traveling wave modulus maxima at the exits of two adjacent traction substations is opposite, the fault occurs between these two traction substations;

[0039] If the maximum polarity of fault current traveling wave modulus at the exits of...

Embodiment 2

[0040] Embodiment 2: as Figure 1-6 As shown, a traveling wave location method for the fault zone of the traction network of a through-type in-phase traction power supply system, the specific steps of the method are:

[0041] A. After a fault occurs on the traction network of the through-type same-phase traction power supply system, the data acquisition devices of each traction substation collect the current within the 10ms time window after the fault occurs;

[0042] B. Obtain the maximum value of the wavelet transform modulus of the fault current signal at the exit of each traction substation;

[0043] C. Compare the modulus maximum polarity of the current traveling wave signal at each outlet;

[0044] If the polarity of the fault current traveling wave modulus maxima at the exits of two adjacent traction substations is opposite, the fault occurs between these two traction substations;

[0045] If the maximum polarity of fault current traveling wave modulus at the exits of...

Embodiment 3

[0048] Embodiment 3: as Figure 1-6 As shown, a traveling wave location method for the fault zone of the traction network of a through-type in-phase traction power supply system, the specific steps of the method are:

[0049] A. After a fault occurs on the traction network of the through-type same-phase traction power supply system, the data acquisition devices of each traction substation collect the current within the 10ms time window after the fault occurs;

[0050] B. Obtain the maximum value of the wavelet transform modulus of the fault current signal at the exit of each traction substation;

[0051] C. Compare the modulus maximum polarity of the current traveling wave signal at each outlet;

[0052] If the polarity of the fault current traveling wave modulus maxima at the exits of two adjacent traction substations is opposite, the fault occurs between these two traction substations;

[0053] If the maximum polarity of fault current traveling wave modulus at the exits of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com