A kind of outer layer etching method of thick copper plate

A thick copper plate and etching technology, which is applied to the removal of conductive materials by chemical/electrolytic methods, electrical components, and printed circuit manufacturing. It can solve problems such as unclean etching, achieve good etching effect, good uniformity, and reduce production scrap. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] This embodiment provides a method for etching the outer layer of a thick copper plate, the thickness of the bottom copper of the outer layer of the thick copper plate is 3OZ, and the thick copper plate includes a first surface (ie, a TOP surface) and a second surface.

[0017] According to the existing positive film process, the outer layer circuit is made on the thick copper plate, which includes the following processes in turn: grinding plate → film attachment → exposure → development → electroplating copper → electrotin plating → film stripping → outer layer etching → tin stripping.

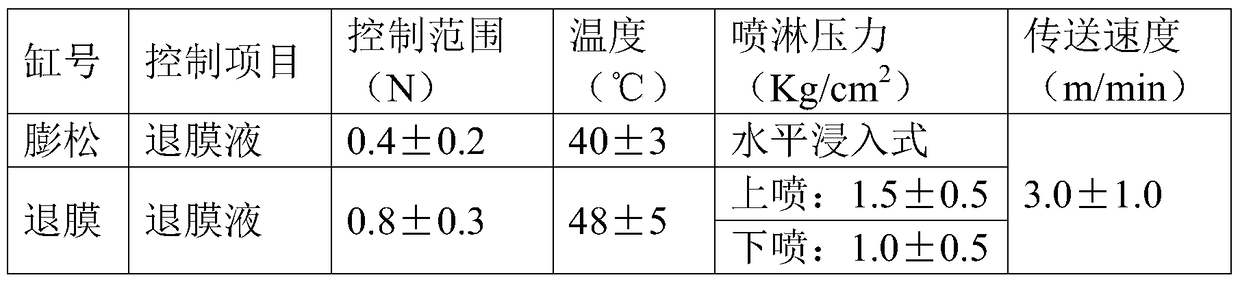

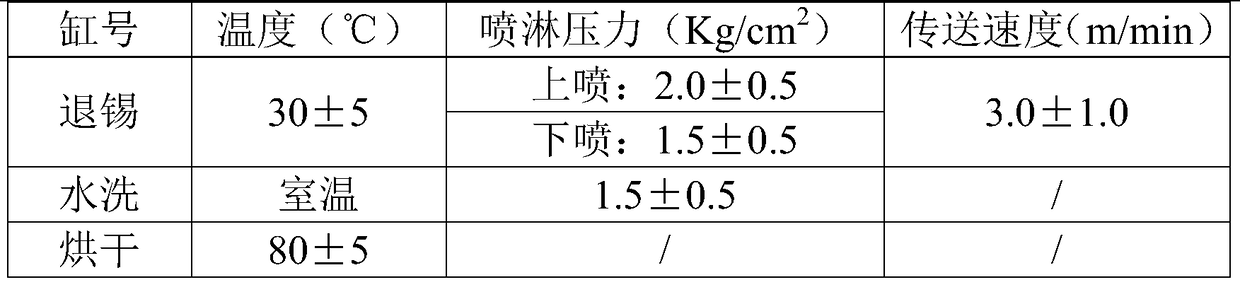

[0018] 1. Before the outer layer is etched, the pre-process is carried out according to the existing technology, as follows: board entry → bulking → film removal → washing → inspection. The process parameters are as shown in the table below (use the film stripping solution commonly used in this field, such as industrial grade sulfuric acid, industrial grade sodium hydroxide).

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com