Stabilized polymer compositions and methods of making same

A polymer and composition technology, applied in the field of stable polymer composition and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0066] According to one embodiment of the invention the stabilized polypropylene composition has a YI after 5 passes of less than -1.

[0067] According to one embodiment of the invention, the YI of the stable LLDPE composition after one pass is less than -4.

[0068] According to one embodiment of the invention, the stable LLDPE composition has a YI of less than 5 after 3 passages.

[0069] According to one embodiment of the invention, the stable LLDPE composition has a YI of less than 6 after 5 passages.

[0070] According to one embodiment of the invention, the stable LLDPE composition has a YI after the gasfade test (fume chamber, 55°C, 4 days) of less than 1.6.

[0071] According to one embodiment of the present invention, the whiteness index of the stable LLDPE composition is at least 27 and meets at least one of the following conditions: YI is less than -4 after one pass, YI is less than 5 after 3 passes, YI is less than 5 after 5 passes Less than 6 after passage, YI ...

Embodiment 1

[0149] Production of premixes of (a) antacids and (b) organic acid metal salts for the Examples provided in Tables 1 and 2 is described as follows. The components to produce a premix according to an embodiment of the invention are presented in the order in which they are added.

[0150] Premix 1 was prepared by dispersing 135.4g of zinc oxide (French Process, >99.7% purity) in 892.1g of fatty acid (acid number 209) in a Parr reactor, adding 0.3g of adipic acid catalyst and dissolving in the reaction In the mixture, heat the reaction mixture to the induction temperature of the reaction and mix and react the mixture at a pressure of 35 psig for 20 min. The reaction vessel is vented to atmospheric pressure while maintaining the temperature above the melting point of the resulting organic acid metal salt reaction product and finally at 130° C. 250 g of zinc oxide (French method, >99.7% purity) were intimately mixed at -150°C to produce a premix stabilizing component. The melt dis...

Embodiment 2

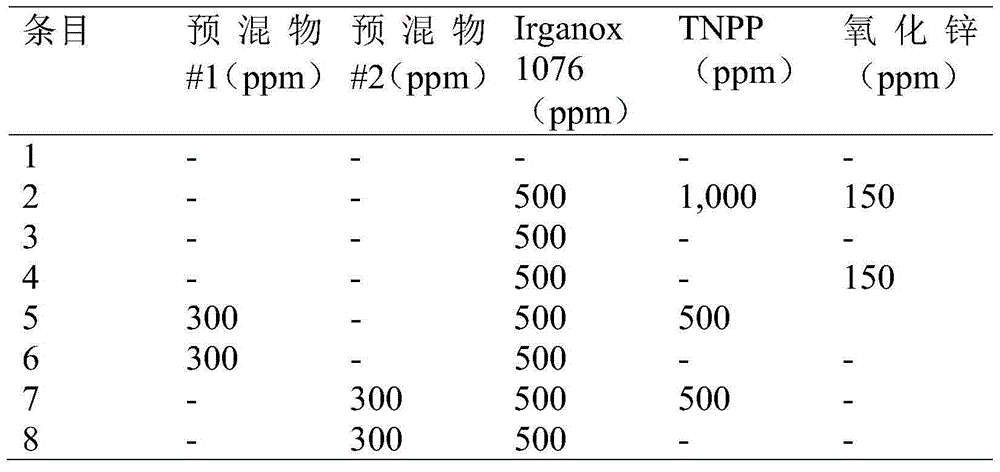

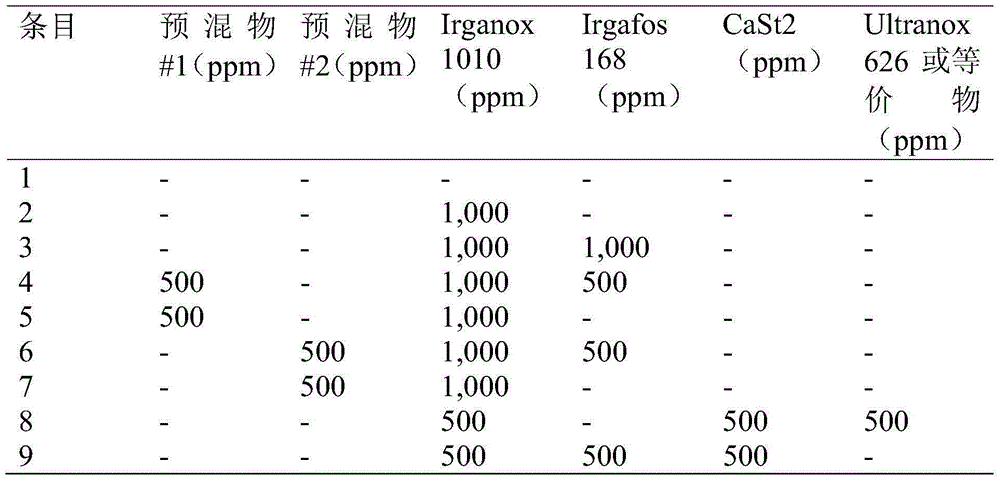

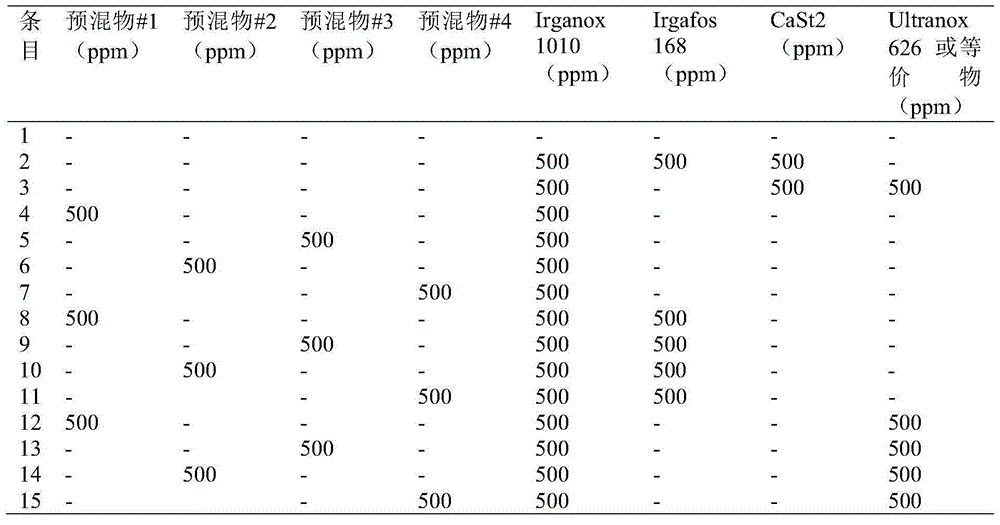

[0155] Table 1: Low Linear Density Polyethylene (LLDPE) Compositions

[0156]

[0157] Entry 1: No Additives

[0158] Item 2: Controls

[0159] 1076: Octadecyl 3,5-di-tert-butyl-4-hydroxyhydrocinnamate

[0160] TNPP: Tris(nonylphenyl)phosphite

[0161] Entry 1 of Table 1 is an unstabilized LLDPE resin containing about 20-30 ppm residual chlorine. For entries 2-8, stabilized mixtures obtained by tumble blending stabilizer additives into LLDPE in a Henschel mixer were processed for testing. Granulation was simulated by performing a zero channel run at 190°C with a nitrogen purge. Using KrausMaffeiBerstorffZE25Ax26D at 225°C without nitrogen purge The twin-screw extruder implements 5-pass extrusion and the melt flow rate (MFR) and yellowness index (YI) are measured after the first, third and fifth passes. Yellowness Index (YI) was determined on a HunterLab ColorQuest XE Colorimeter and Melt Flow Rate (MFR) was determined on a Tinius Olsen Extrusion Plastometer.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com