Liquid wax rotating device of wafer and waxing method

A technology of liquid wax and wafer, which is applied to the device and coating of the surface coating liquid, which can solve the problems of cumbersome processing process, product quality impact, poor uniformity, etc., to reduce production costs, eliminate local pits, good wax effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

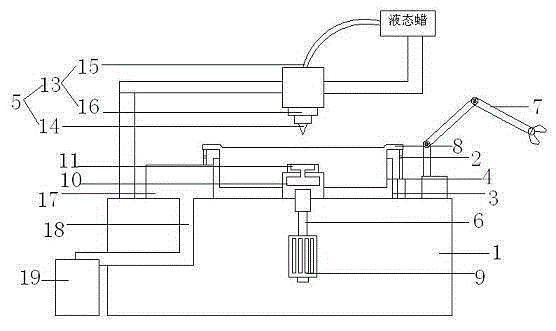

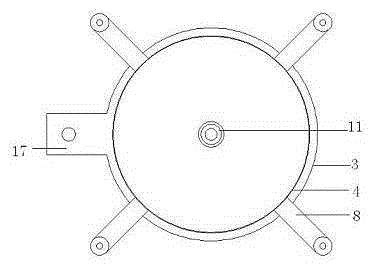

[0021] A liquid wax spinning device for a wafer is characterized in that it includes a workbench 1, a telescopic cylinder 2, an outer frame body 3, a baffle plate 4, a wax dropping device 5, a rotary adsorption mechanism 6 and a mechanical arm 7, and the workbench 1. It is installed horizontally. The outer frame body 3 is cylindrical and fixedly installed on the workbench 1. The baffle plate 4 is cylindrical. The baffle plate 4 and the outer frame body 3 fit together. The upper edge of the baffle plate 4 is There are four symmetrically arranged support rods 8, the two ends of the support rods 8 are fixedly connected with the upper end of the telescopic cylinder 2 and the baffle 4 respectively, and the telescopic cylinder 2 is fixedly arranged on the workbench 1, realizing the baffle 4 Free lift in the vertical direction;

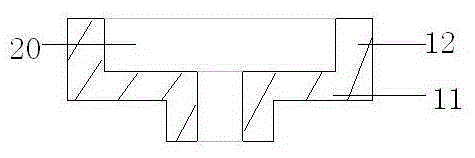

[0022] The rotary suction mechanism 6 includes a rotary motor 9, a vacuum generator 10 and a suction cup 11. The suction cup 11 is circular and includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com