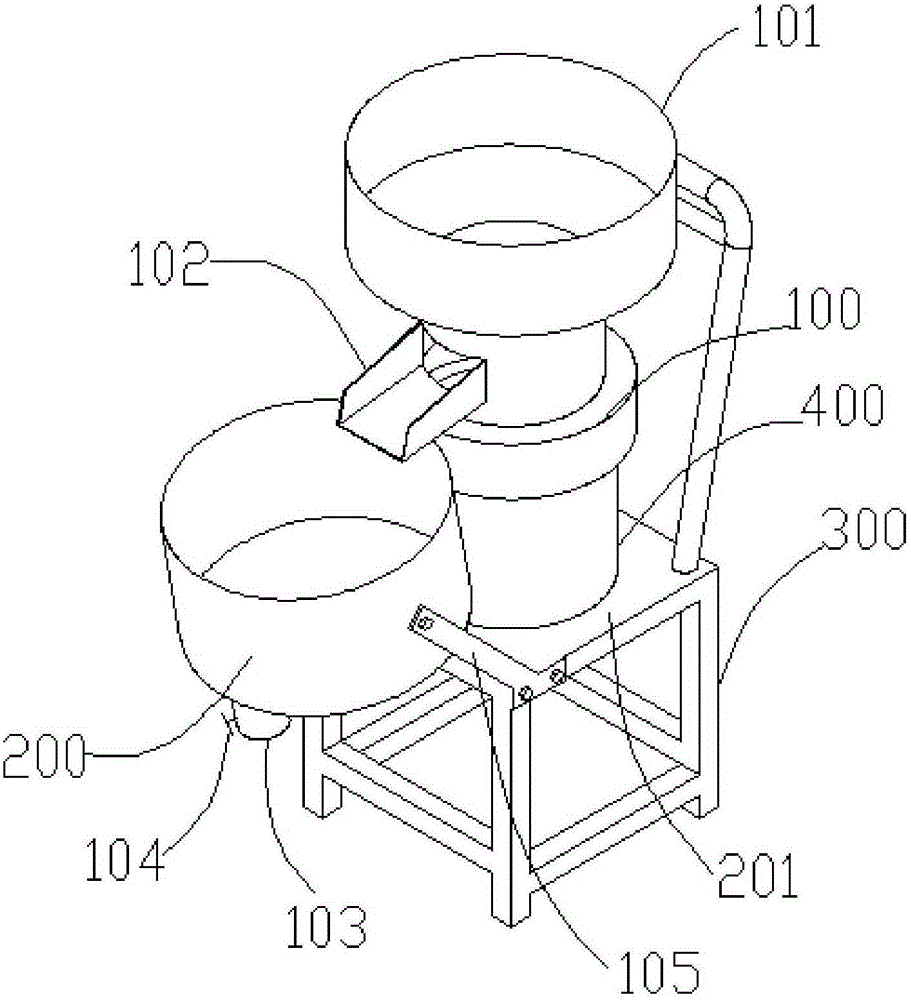

Automatic filter sieve device

An automatic filtration and sieve technology, applied in sieves, solid separation, grids, etc., can solve the problems of single sieve structure, inconvenient storage and collection of raw materials, etc., and achieve easy use, convenient processing and manufacturing, and simple and reasonable device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

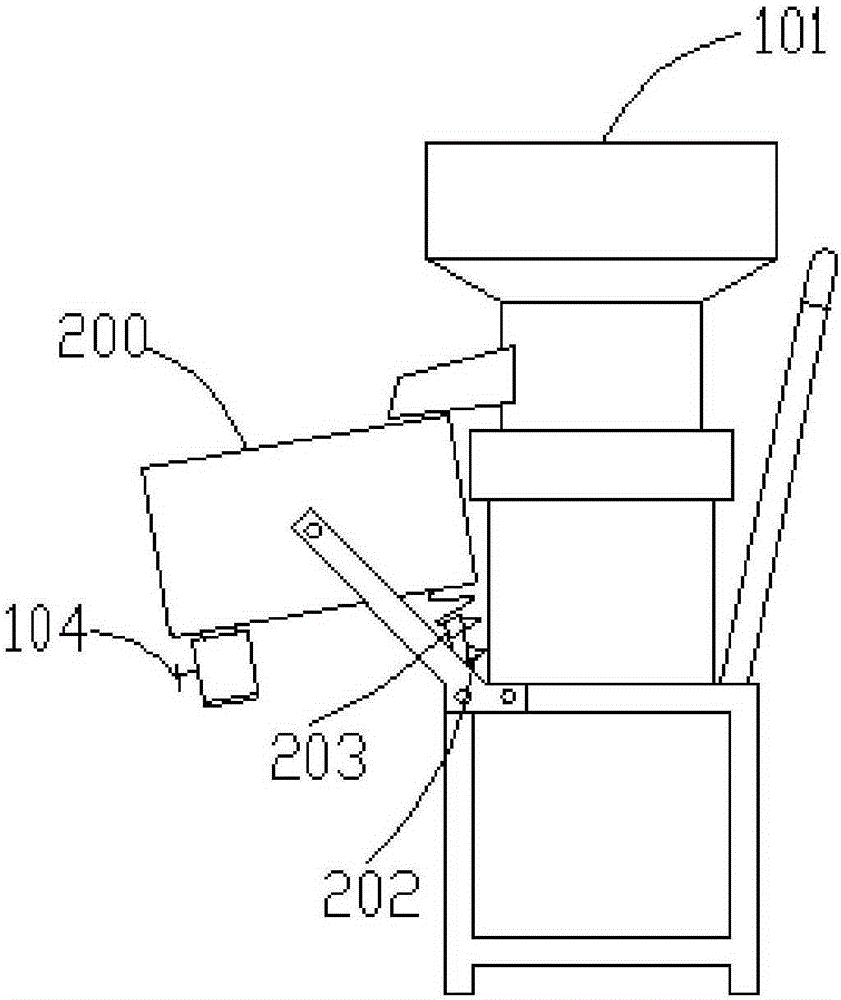

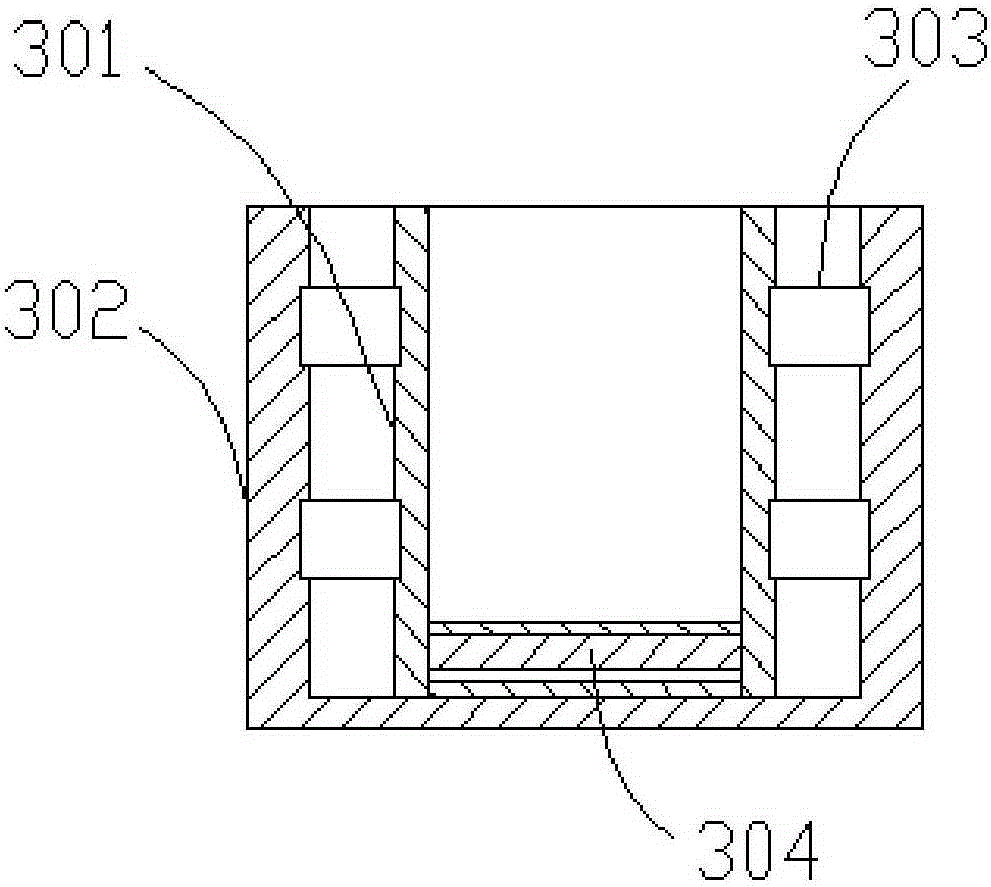

[0030] In the actual processing process, some raw materials need to be filtered to meet the use requirements. Vibrating filter screens are widely used in the prior art. Can be widely used in chemical industry, food industry and other industries, such as: paint, ink, starch, soybean milk, mud, etc. Then, in the prior art, after the raw materials to be filtered are filtered through the filter screen, a separate container needs to be used to store them, which is inconvenient to operate; the raw materials cannot be collected on demand, which is easy to cause waste of raw materials; at the same time, the redundant raw materials In the hopper directly stored in the filter screen, the service life of the hopper is shortened, which in turn shortens the service life of the filter screen and increases the use cost.

[0031] In view of this, the designer of the present invention has designed a kind of automatic filter screen device, and this device structure is simple and reasonable, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com