A device and method for sheet metal soft mold thermoforming based on heterogeneous metal rubber

A metal rubber, heterogeneous technology, applied in the field of sheet metal soft mold thermoforming device, can solve the problems of complex sealing device, sensitive forming temperature, high cost, etc., achieve the goal of increasing forming limit, exerting plastic deformation ability and improving forming quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

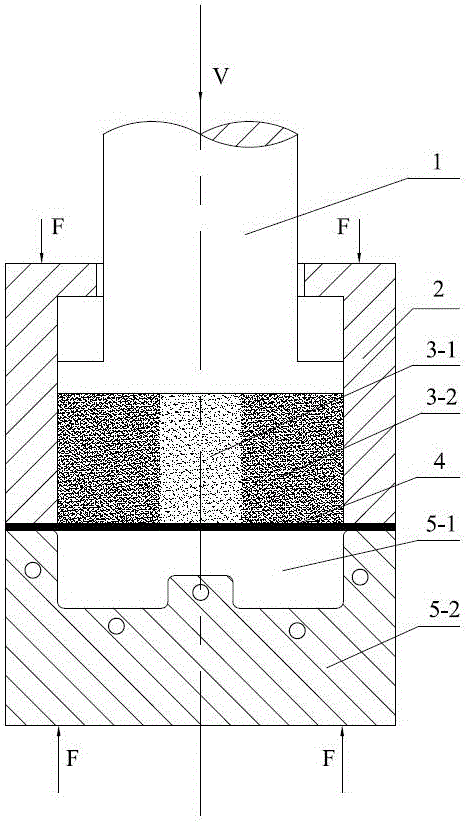

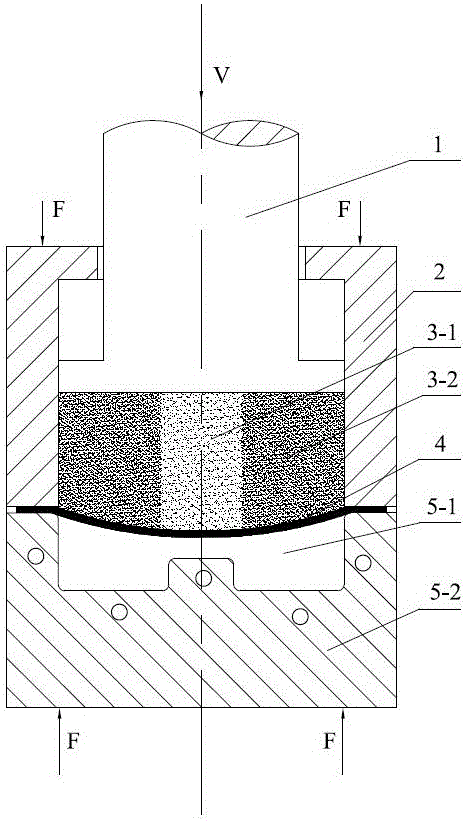

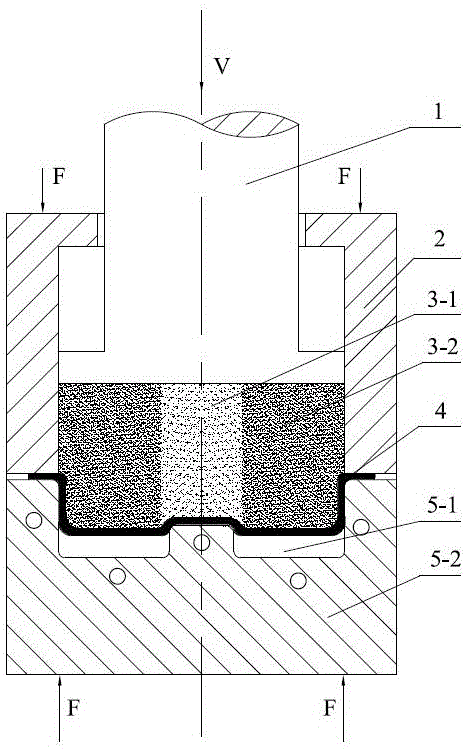

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises plunger 1, container frame 2, heterogeneous metal rubber, sheet material part 4 and have the die 5-2 of cooling pipeline, described die 5-2 with cooling pipeline The upper end surface of -2 is provided with a die cavity 5-1, the container frame 2 and the die 5-2 with a cooling pipeline are set up and down, the container frame 2 is set on the outside of the plunger 1, and the plunger 1 The head of the head is located in the inner cavity of the container frame 2, and the heterogeneous metal rubber is placed in the inner cavity formed by the lower surface of the plunger 1 and the inner wall of the container frame 2. The gap of the heterogeneous metal rubber used in the forming process depends on the plate The shape of the part 4 and the modulus of elasticity required for each stage of forming are determined.

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1~Figure 5 Describe this implementation mode, this implementation mode is realized through the following steps:

[0023] Step 1. Determine the number of wire turns per unit volume in each part of the heterogeneous metal rubber used according to the shape of the plate part 4 to be formed and the modulus of elasticity required for each stage of forming n ,

[0024] n =4(1-Π) / ( π 2 d np 2 d cp )

[0025] In the formula, Π——the porosity of the metal rubber body, d np - wire diameter, d cp - the pitch diameter of the spiral coil;

[0026] Step 2, heating the plate part 4 to be formed to the temperature required for forming;

[0027] Step 3, placing the plate part 4 to be formed between the lower surface of the container frame 2 and the upper surface of the die 5-2 with a cooling pipeline, and clamping the plate part 4 to be formed;

[0028] Step 4, pushing the plunger 1 to drive the heterogeneous metal rub...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 1~Figure 5 To describe this embodiment, in this embodiment, the variation range of the porosity of the heterogeneous metal rubber in step 1 is 0.2-0.8. Within this range, the heterogeneous metal rubber can sufficiently change the material properties including elastic modulus. Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com