Machining cutter preventing orifice edge breakage

A technology for machining cutting tools and edge chipping, which is applied in the direction of manufacturing tools, metal processing equipment, drilling tool accessories, etc. It can solve the problems of low efficiency, many processes, and edge chipping of holes, so as to reduce costs, improve product quality, reduce The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

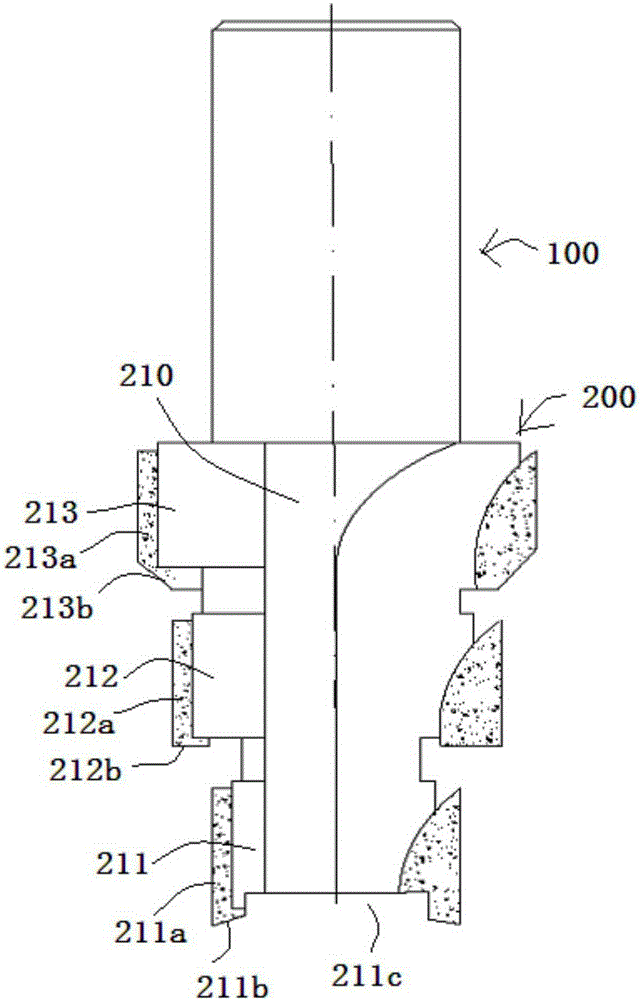

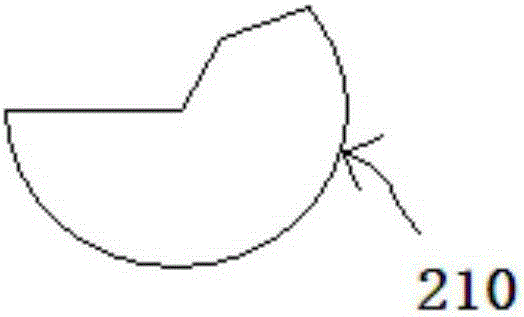

[0013] see figure 1 and figure 2 The shown processing tool for preventing hole chipping includes a cutter bar 100 and a cutter body 200 connected to the front end of the cutter bar. The cutter body 200 includes a cylinder 210 without a fan-shaped corner block, and a cylinder 210 without a fan-shaped corner block. That is, a fan-shaped corner block is dug out for the periphery of the cylinder, such as figure 2 shown. The cylinder 210 is sequentially provided with a first notch annular knife surface 211 , a second notch annular knife surface 212 and a third notch annular knife surface 213 whose outer diameter gradually increases from the front end to the rear end, and the first notch annular knife surface A first sharpening layer 211a, a second sharpening layer 212a and a third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com