Vacuum cup/kettle mouth sealing machine

A welding junction, cup and pot technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of increased product cost, high product defect rate, low efficiency, etc., to achieve stable performance, good product quality, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

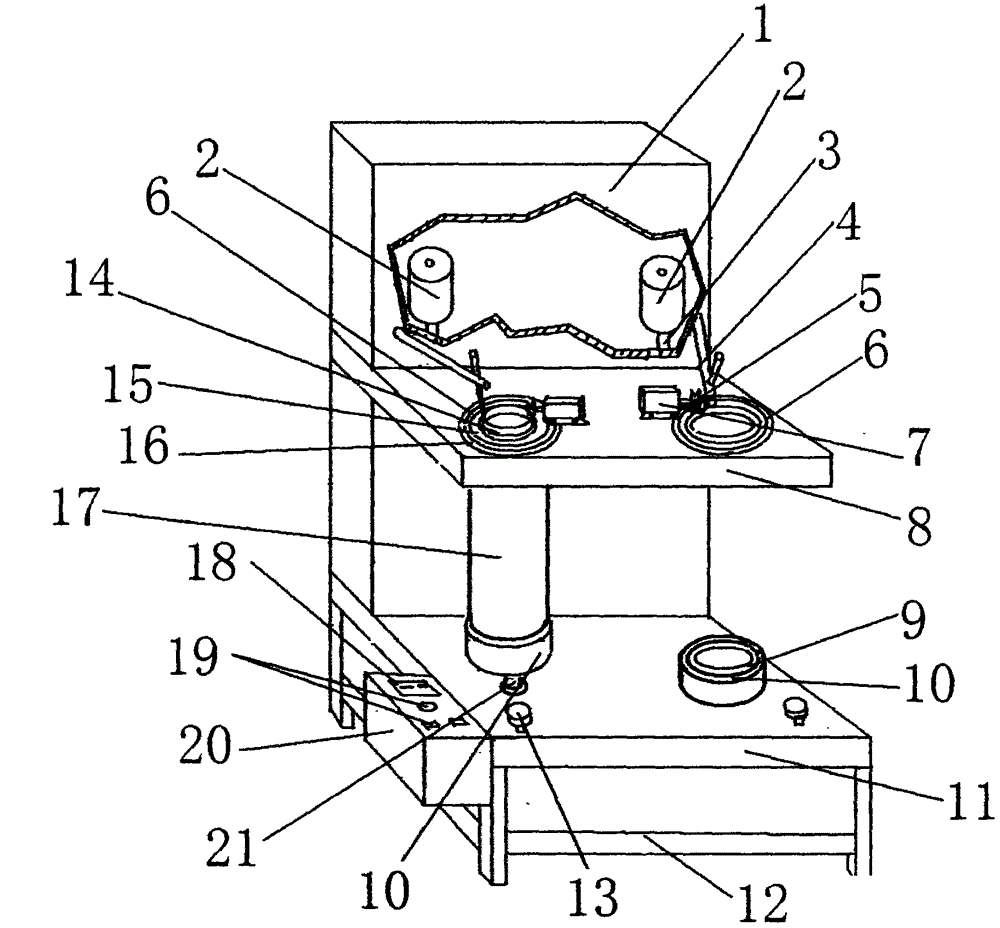

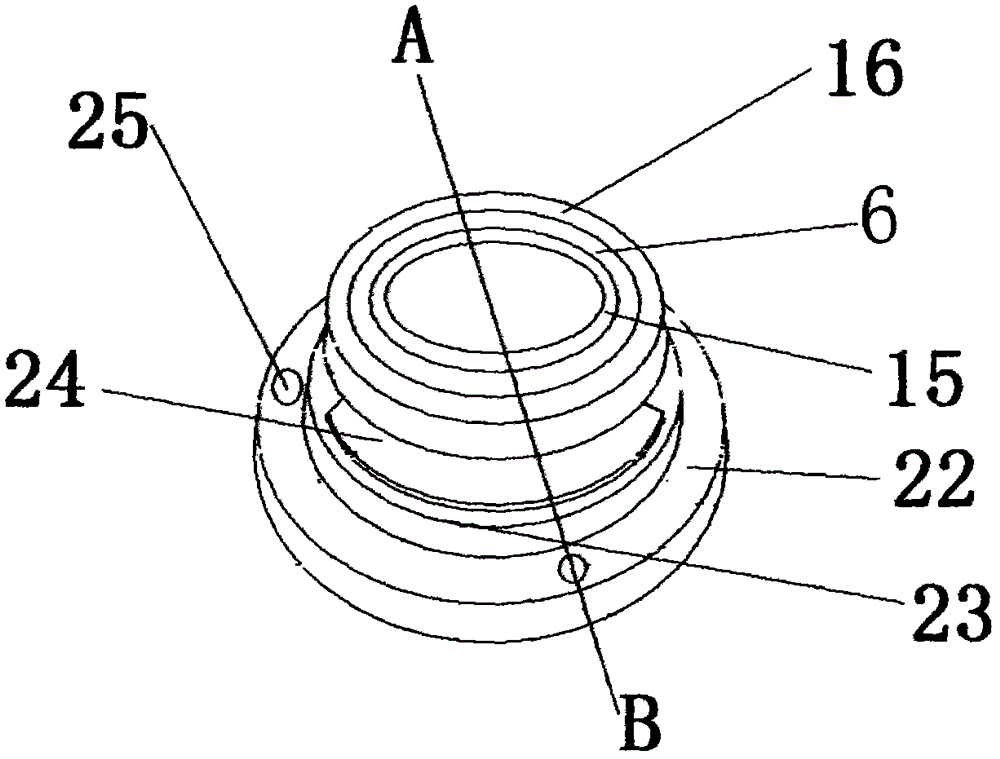

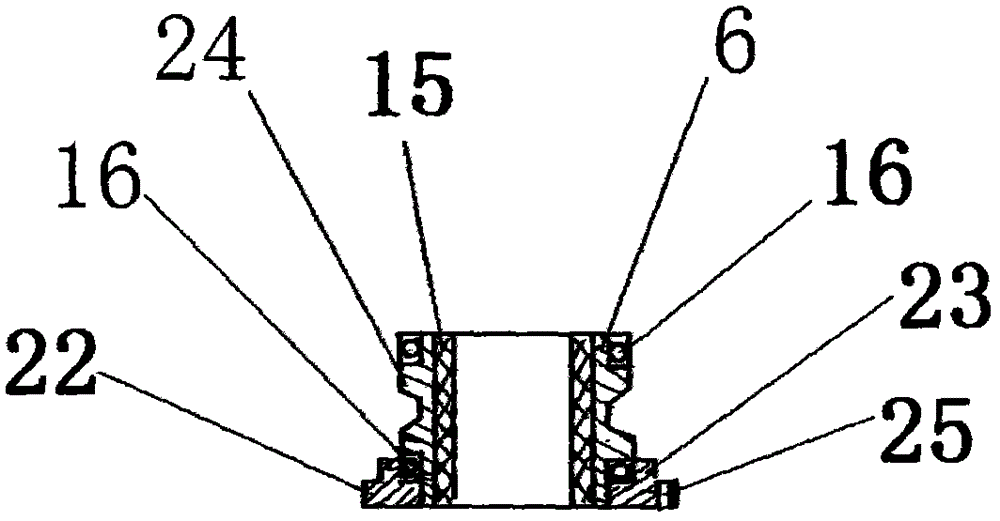

[0012] exist figure 1 Among them, the motor box 1 is made of angle iron and iron plate. In front of the motor box 1, there are an upper platform 8, a lower platform 11 and a fixed plate 12. On the upper platform 8, there are two roller fixing blocks 7, and the roller fixing blocks There is a bearing in 7, and a steel shaft 3 is arranged in the bearing, and a grooved roller 5 is arranged on the head of the steel shaft 3, and a cup edge 14 and a nylon model 15 are arranged on the bottom of the grooved roller 5, and the outside of the nylon model 15 There is a fixed ring 6, and there is a bearing 16 outside the fixed ring 6, and the bearing 16 is fixed on the upper plate 8, and the fixed ring 6 and the following fixed disk are conjoined, and the fixed disk is provided with screw holes and connected with a retaining ring. There is a bearing 16 in the retaining ring, a V-belt pulley is arranged on the retaining ring, two stepping motors 2 and two welding torches 4 for argon arc wel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap