Rotary drum type vegetable cutter

A vegetable cutting machine and drum technology, applied in metal processing, etc., can solve the problems of poor vegetable cutting uniformity, low production efficiency, heavy vegetable cutting tasks, etc., and achieve the effect of convenient use and maintenance, simple structure, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

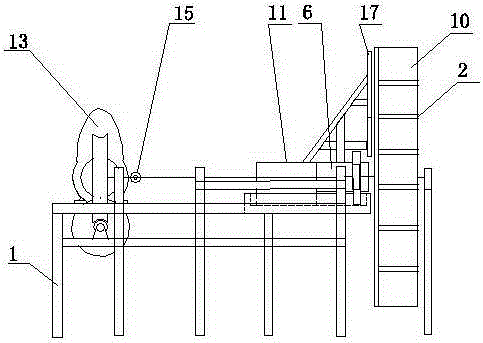

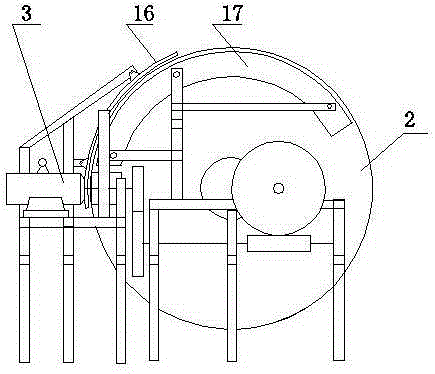

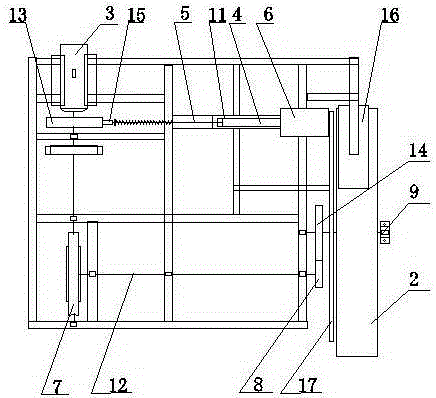

[0019] The drum type vegetable cutter includes a frame 1, a drum 2, a motor 3, a cutter head slider 4, a cutter head rod 5, a cutter 6, a reversing turbine 7 and an incomplete gear 8. One end of frame 1 is equipped with rotating cylinder 2 by mounting shaft 9. A plurality of dish receiving grooves 10 are arranged on the circumference of the drum 2 . The vegetable receiving groove 10 is a rectangular cavity, and the top and inner side of the vegetable receiving groove 10 are respectively open. The top side of the drum 2 is equipped with a circumferential guard plate 16 through the frame 1; the inner side of the upper end of the drum 2 is equipped with an end guard plate 17 through the frame 1. The circumferential guard plate 16 and the end face guard plate 17 are fitted and slidably connected with the drum 2 respectively.

[0020] The other end of the frame 1 is equipped with a motor 3, and the frame 1 between the motor 3 and the drum 2 is fixed with a mounting seat 11, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com