Ceramic slurry, ceramic porous oil guiding body and heating assembly for electronic cigarette

A technology of ceramic slurry and heating components, which is applied in the direction of ceramic products, smoker supplies, applications, etc., can solve the problems of affecting atomization efficiency, affecting service life, and easy to generate dust and residue, so as to increase atomization efficiency and reduce The effect of small production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

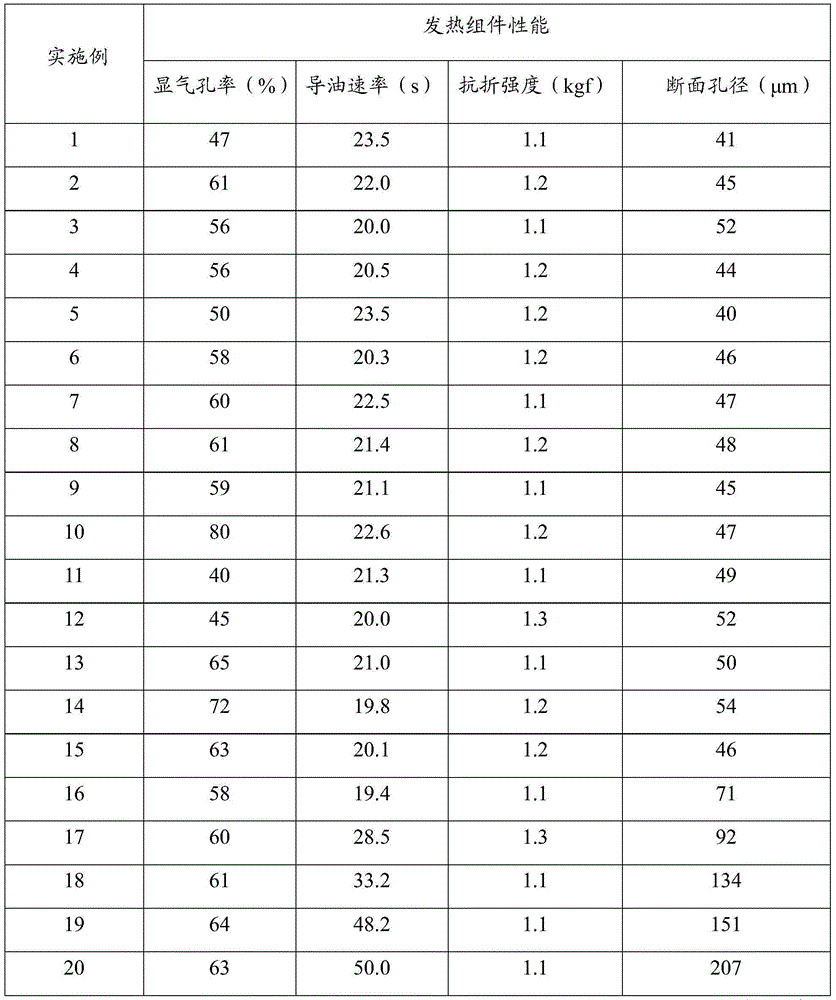

Embodiment 1

[0040] An embodiment of the ceramic slurry of the present invention, the ceramic slurry is prepared by the following method:

[0041] The skeleton material, soil material, pore-forming agent and additive are mixed to obtain a mixture, wherein the framework material is alumina, the soil material is kaolin, the pore-forming agent is graphite powder, and the additive is carboxymethyl cellulose , the framework material accounts for 45% of the total weight of the mixture, the soil material accounts for 10% of the total weight of the mixture, the pore-forming agent accounts for 30% of the total weight of the mixture, and the additive accounts for the 15% of the total weight of the mixture; the mixture was formulated with water into a suspension with a solid content of 40%, and then ball milled in a ball mill tank for 8 hours to obtain a uniformly mixed ceramic slurry.

[0042] An embodiment of the ceramic porous oil-guiding body of the present invention, the ceramic porous oil-guidi...

Embodiment 2

[0050] An embodiment of the ceramic slurry of the present invention, the ceramic slurry is prepared by the following method:

[0051] The framework material, soil material, pore-forming agent and additives are mixed to obtain a mixture, wherein the framework material is alumina, the soil material is kaolin, the pore-forming agent is polyethylene glycol, and the additive is glycerin. The framework material accounts for 50% of the total weight of the mixture, the soil material accounts for 10% of the total weight of the mixture, the pore-forming agent accounts for 35% of the total weight of the mixture, and the additive accounts for 10% of the total weight of the mixture. 5% by weight; the mixture was formulated with water into a suspension with a solid content of 45%, and a uniformly mixed ceramic slurry was obtained after ball milling in a ball mill jar for 7 hours.

[0052] An embodiment of the ceramic porous oil guide body of the present invention, the ceramic porous oil gui...

Embodiment 3

[0059] An embodiment of the ceramic slurry of the present invention, the ceramic slurry is prepared by the following method:

[0060] A mixture is obtained by mixing skeleton material, soil material, pore-forming agent and additives, wherein the skeleton material is alumina, the soil material is kaolin, the pore-forming agent is starch, the additive is 920 lubricant, and the The skeleton material accounts for 55% of the total weight of the mixture, the soil material accounts for 10% of the total weight of the mixture, the pore-forming agent accounts for 30% of the total weight of the mixture, and the additive accounts for 10% of the total weight of the mixture. 5% of 5%; the mixture was formulated with water into a suspension with a solid content of 50%, and a uniformly mixed ceramic slurry was obtained after ball milling in a ball mill jar for 10 hours.

[0061] An embodiment of the ceramic porous oil-guiding body of the present invention, the ceramic porous oil-guiding body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| processing temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com