Integral ballast bed and tunnel bottom disease control method based on combined support and grouting formwork

A technology of disease control and integral ballast bed, which is applied to roads, tracks, ballast layers, etc., can solve the problems of difficulty in controlling the fluidity of slurry, affecting the support effect of inserted steel plates, and the lack of tightness of the steel plates, so as to improve the flow of slurry and The reinforcement effect is not easy to control, fast and efficient grouting to reinforce the diseased area, and the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

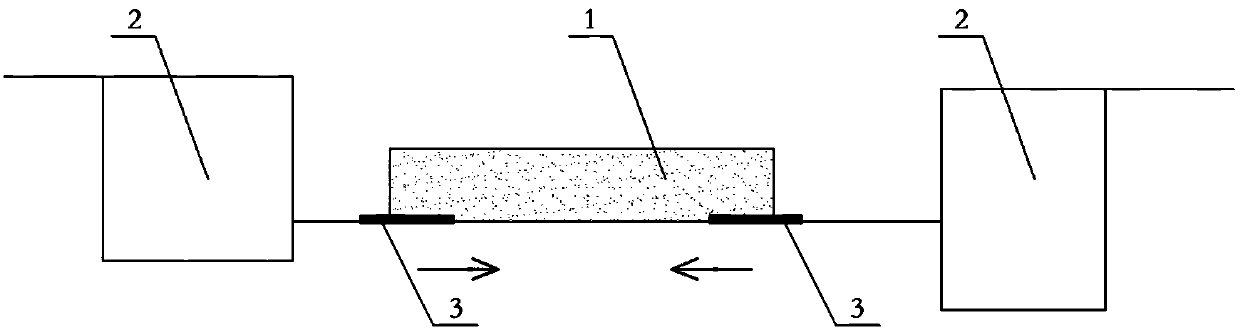

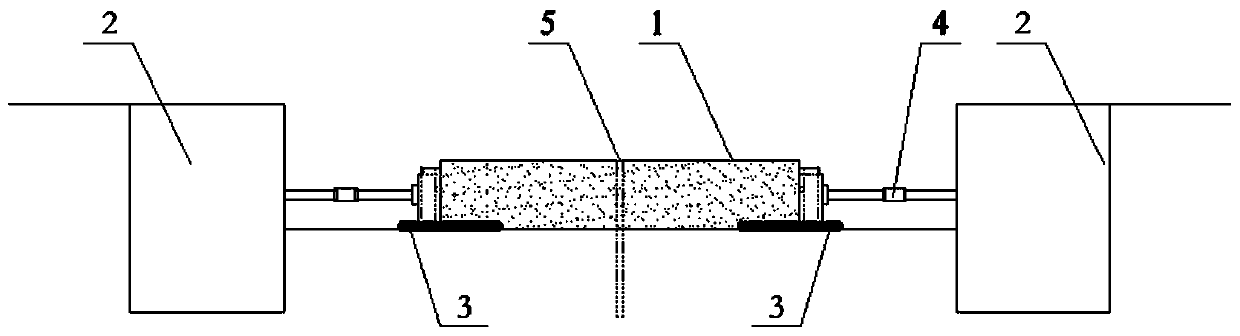

[0051] In the present invention, the ballast bed in the diseased section is firstly supported by the combined steel plate support 3, and then the grouting formwork 4 is installed on both sides of the ballast bed in the diseased section to control the disease of the ballast bed and the tunnel bottom.

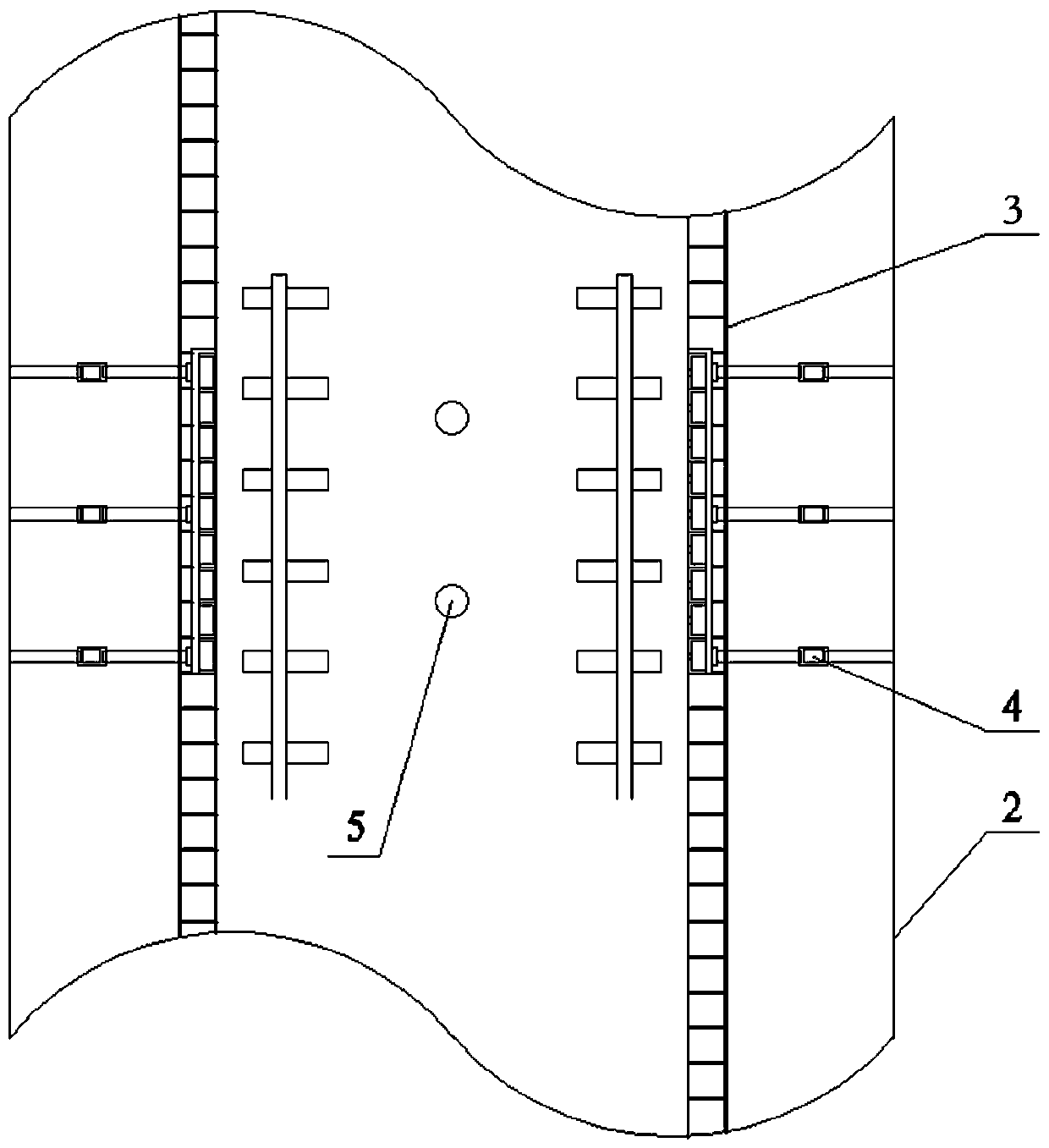

[0052] The structure of the combined steel plate support 3 is as follows Figure 4 , 5 As shown, it includes an upper layer steel plate 31 and a lower layer steel plate 32 with the same length connected. The upper layer steel plate 31 includes two small steel plates with the same shape and size. , The welding adopts groove welding, and the edges of the two small steel plates and the lower steel plate are aligned and welded. The upper surface of the upper steel plate 31 and the lower surface of the lower steel plate 32 are drilled with connected sawtooth grooves 33. The main function of the sawtooth grooves 33 is to realize the occlusion of the combined steel plate with the top, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com