Auto-passing phase separation replaceable type ground magnetic sensor for electric locomotive

A ground magnetic sensor, automatic over-phase technology, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of improper installation of four screws, hidden dangers of safe operation of locomotives, and affecting the safe operation of trains, etc. Efficiency and skylight utilization, improving installation accuracy and safety and stability, and the effect of convenient and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

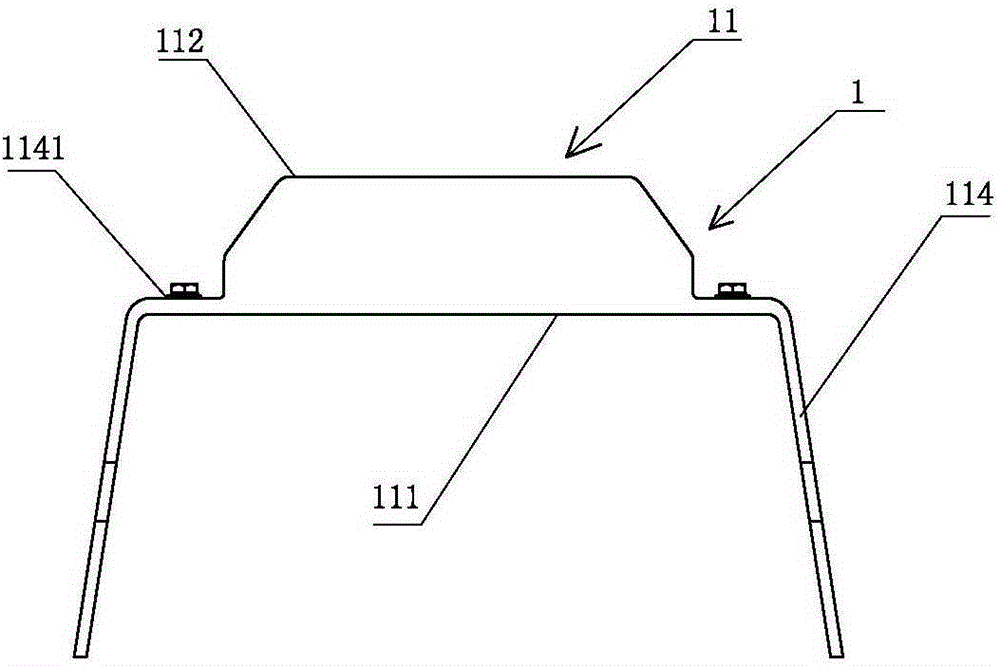

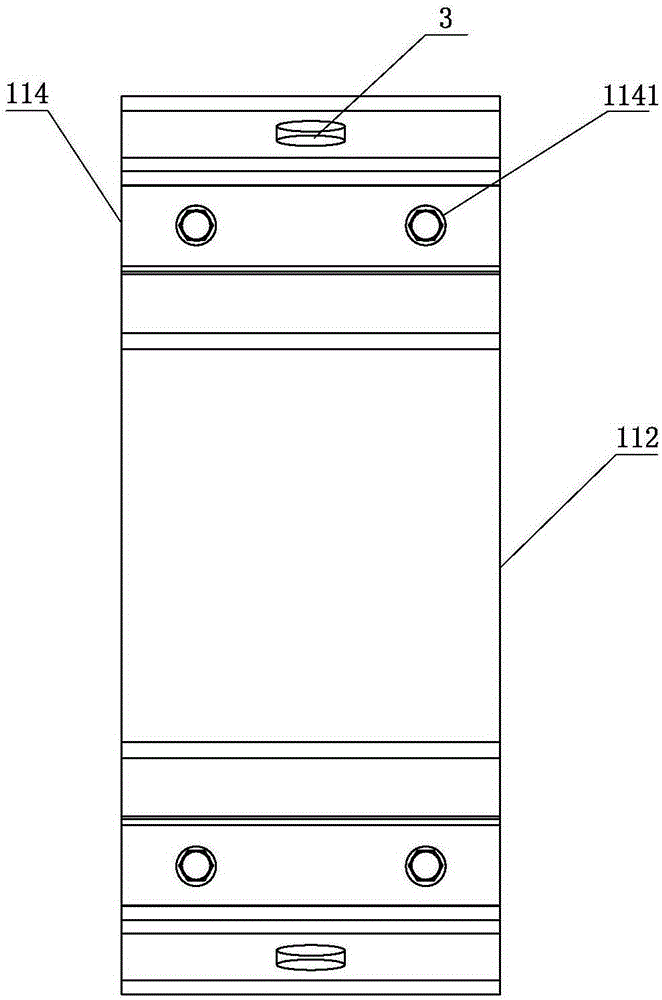

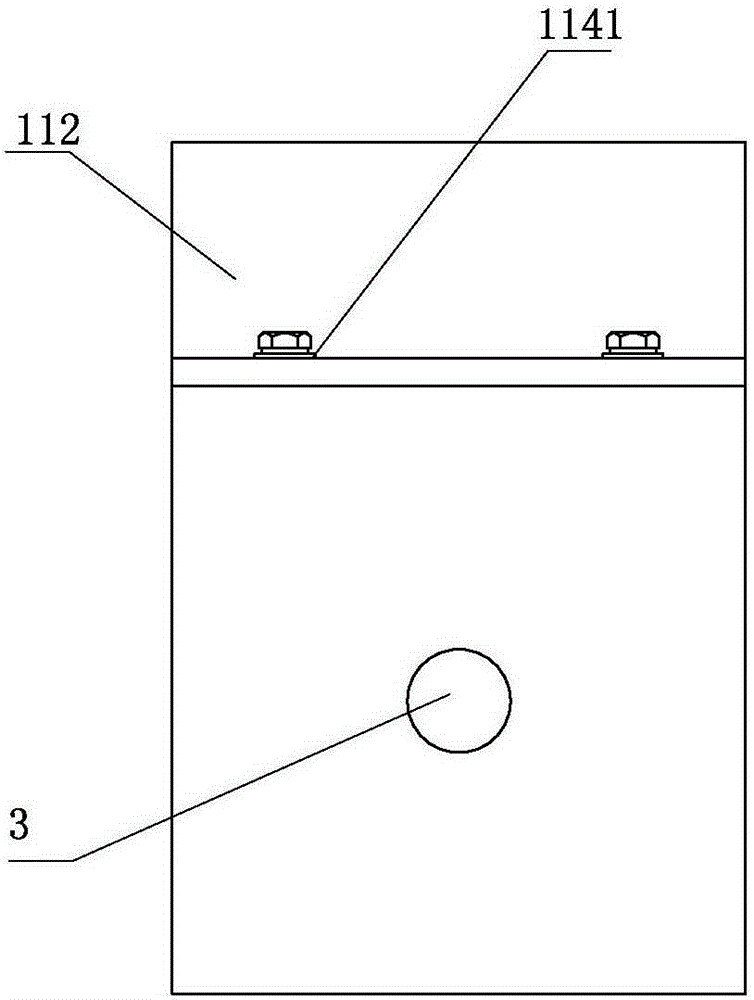

[0033] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, an electric locomotive automatic over-phase replaceable ground magnetic inductor, including a magnetic steel part 1, a special sleeper part, the magnetic steel part 1 includes a magnetic steel 11, The magnetic steel 11 comprises an iron base plate 111, and a stainless steel trapezoidal cover 112 is installed on the iron base plate 111; in the middle part of the base plate 111 in the trapezoidal cover 112, a magnet 113 is bonded thereon using magnetic special glue; On both sides of the base plate 111, bolts are respectively used to pass through the screw holes 1141 on the base plate 111, the cover 112, and the magnetic wing 114 to fix the three together;

[0034]The special sleeper part includes a sleeper 21, a magnetic steel support frame 22, and embedded parts for nuts; a trapezoidal groove is set on the sleeper 21, and the magnetic steel support frame 22 is welded by an iron bottom plate 221 and two stainless steel side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com