A high dam and large reservoir ultra-deep water retaining and venting system and its operating method

A venting system and ultra-deep technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as inability to discharge, inability to maintain the opening and closing of water retaining gates, and difficulty in effectively ensuring system safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

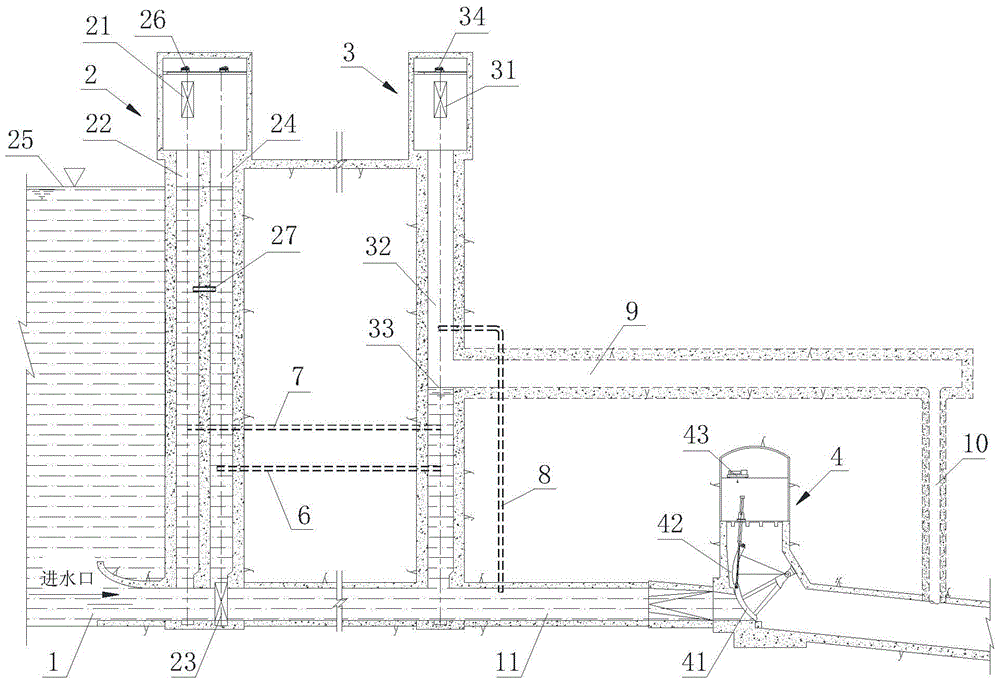

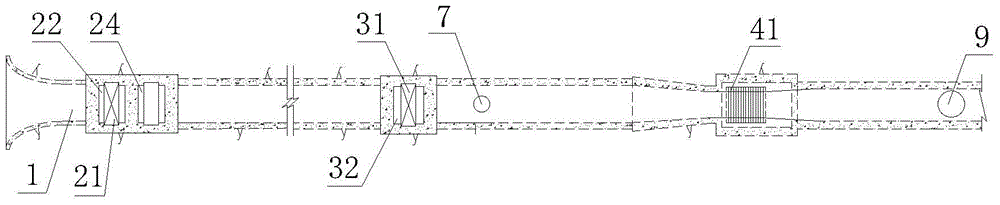

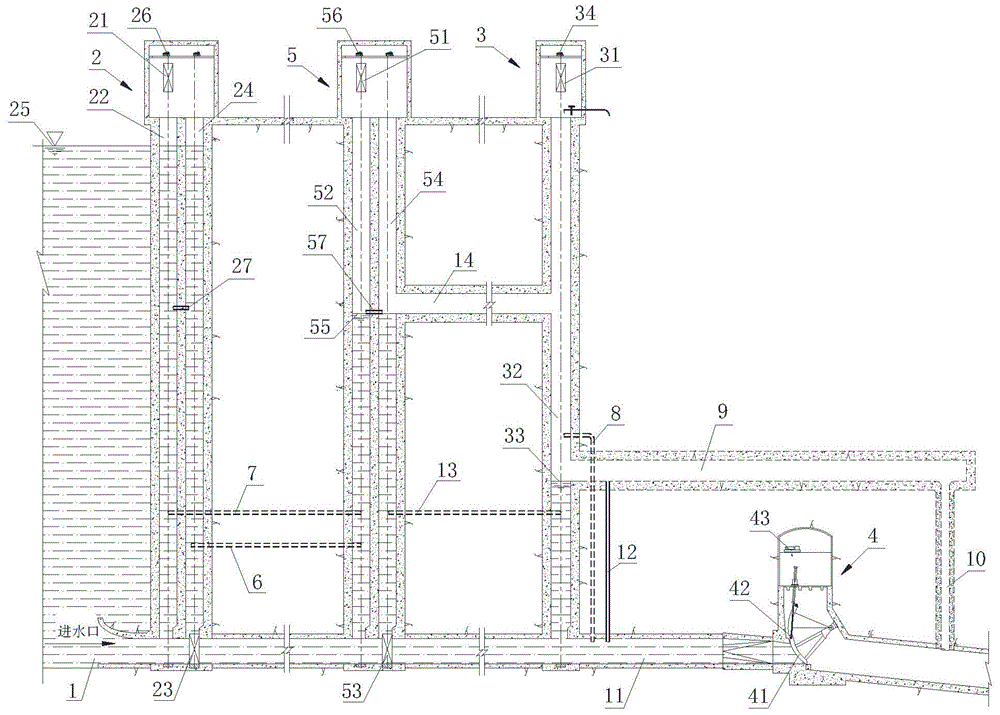

[0100] Such as Figure 1 to Figure 4 As shown, a high dam and large reservoir ultra-deep water retaining and venting system according to the present invention includes a first-stage gate system 2, a final-stage gate system 3, and a final-stage arc gate system 4 arranged in sequence on the tunnel 1. There is also a secondary gate system 5 between the first-level gate system 2 and the last-level gate system 3, and the first-level gate system 2 is connected to the downstream level through the first-level external communication pipe 6 and the first-level external maintenance communication pipe 7 respectively. The gate system is connected, the final gate system 3 is located at the final section 11 of the tunnel 1, and the secondary gate system 5 and the final gate system 3 are connected throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com