Emergency release device for cryogenic fluid handling arm

A technology of cryogenic fluid and detachment device, which is applied in the direction of gas/liquid distribution and storage, container discharge method, container filling method, etc. It can solve the problem that the sealing between the valve core and the valve body is difficult to ensure, the requirement of rapid separation cannot be met, and the quality cannot be guaranteed. and other issues to achieve the effect of ensuring sealing performance, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

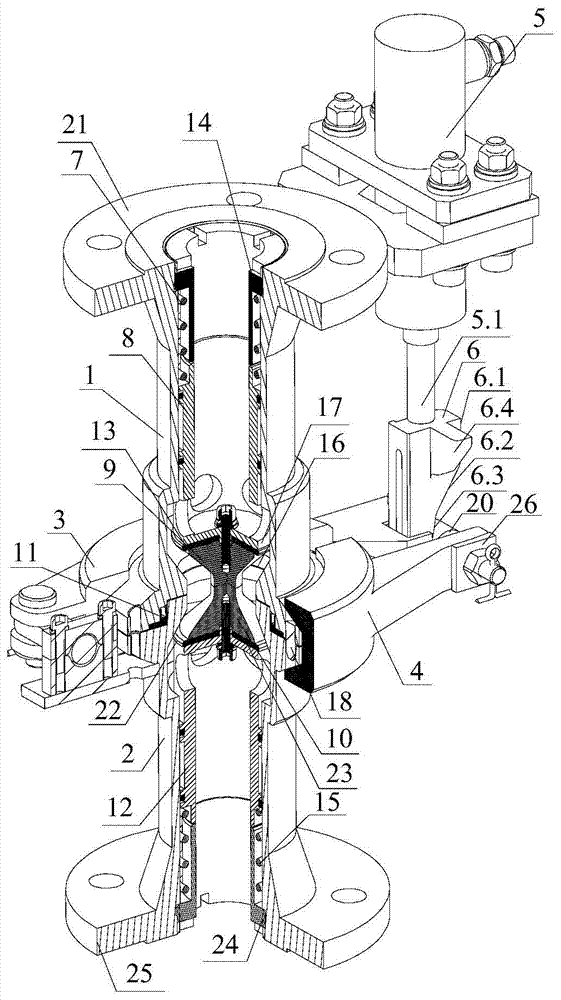

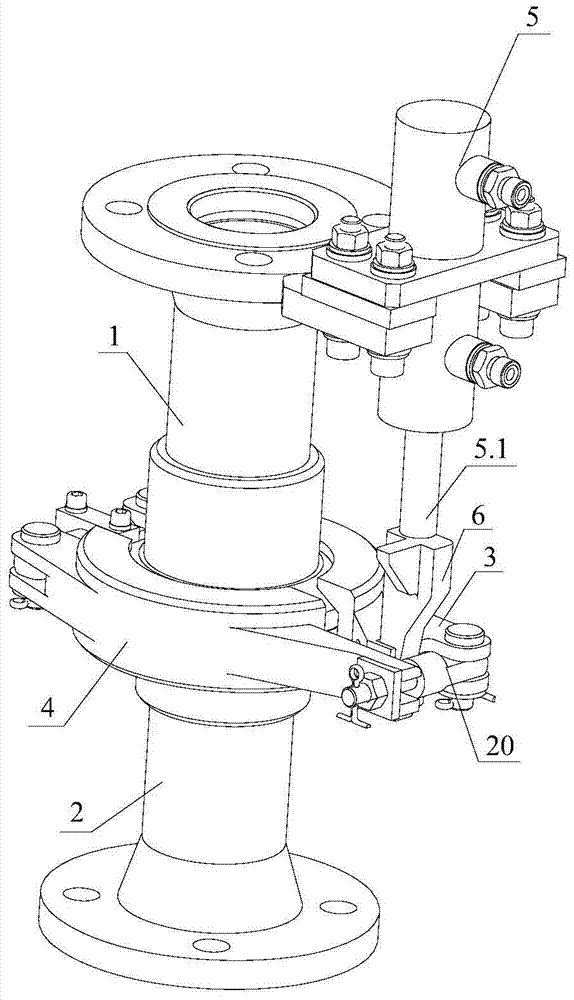

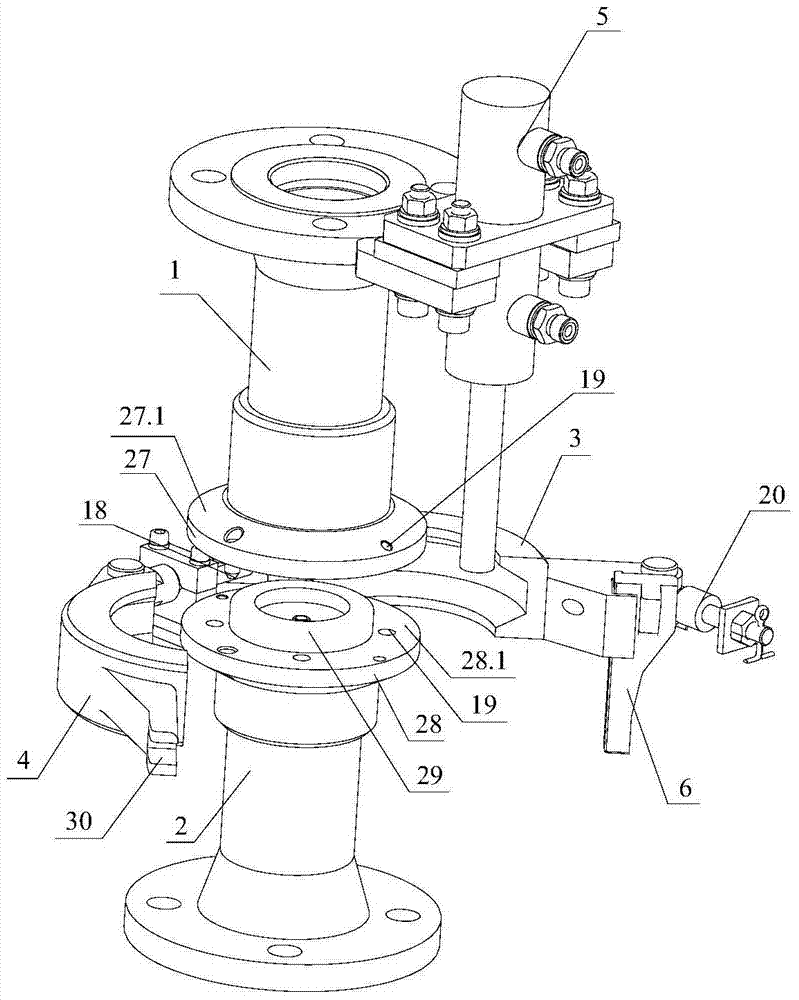

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] combine figure 1 , figure 2 The emergency release device for the cryogenic fluid loading and unloading arm shown includes the upper valve body 1 of the self-sealing valve, the upper valve core arranged in the upper valve body 1 of the self-sealing valve, the lower valve body 2 of the self-sealing valve, and the lower valve body 2 of the self-sealing valve. The lower valve core, the clamp assembly clamping the upper valve body 1 of the self-sealing valve and the lower valve body 2 of the self-sealing valve together, and the hydraulic cylinder 5 for driving the clamp assembly to separate.

[0027] The clip assembly includes a first clip 3, a second clip 4 rotatably connected to the first clip 3, a swing bar 20 and a push block 6, one end of the first clip 3 is connected to one end of the swing bar 20 through a rotating shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com