Fritted porcelain forming baking oven

A soft porcelain and car body technology, applied in drying, drying machine, solar thermal device and other directions, can solve the problems of affecting production efficiency, small baking volume, difficult to evenly distribute the temperature field of the baking car, etc. The effect of prolonging the residence time and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

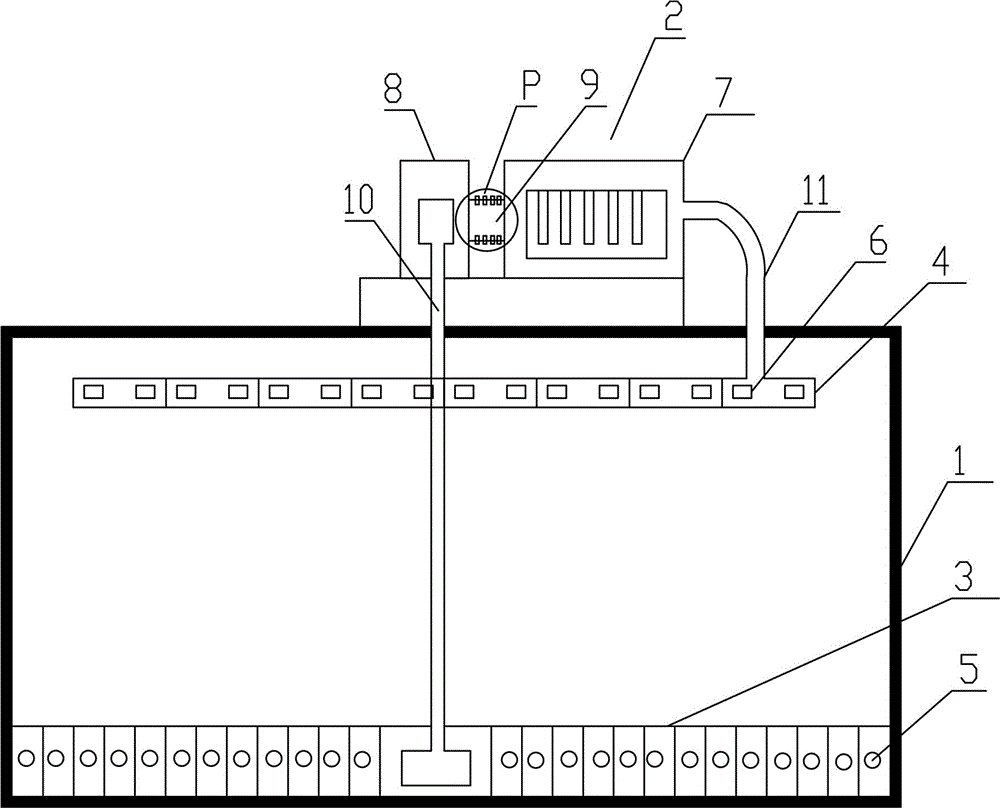

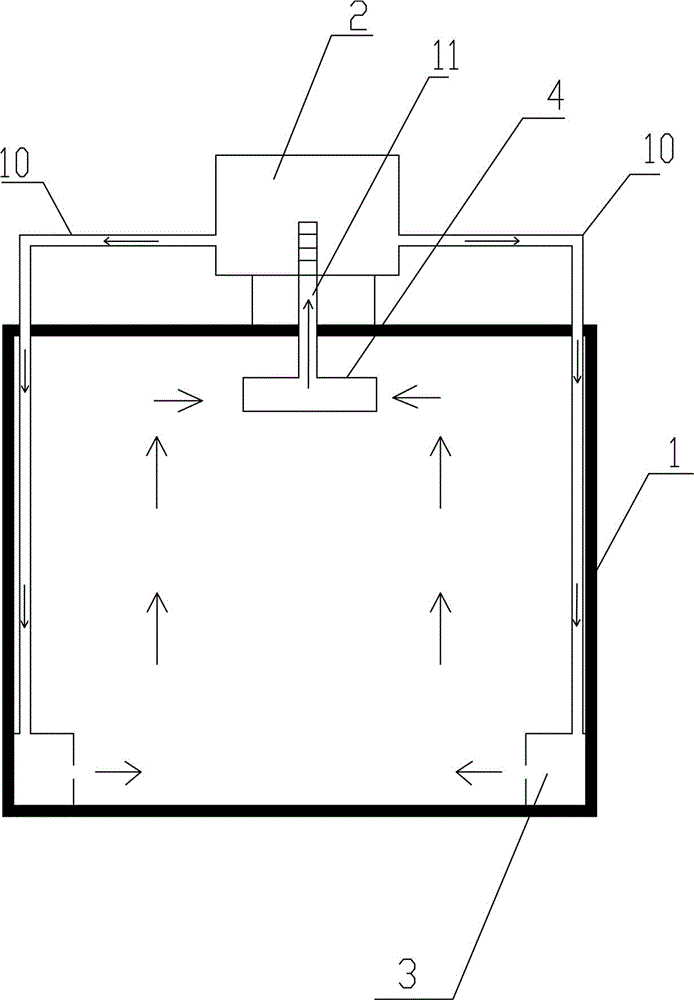

[0015] like figure 1 As shown, a soft porcelain molding baking box includes a box body 1 (15 meters long, 2.5 meters wide, and 2 meters high) made of heat-insulating materials, and a gas heating device 2 arranged on the outer top surface of the box body 1 1. Two heat dissipation chambers 3 arranged symmetrically on the inner bottom plate of the car body 1, and a recovery chamber 4 arranged in the middle of the inner top plate of the car body 1. The surface of the heat dissipation chamber 3 is provided with heat dissipation holes 5, and the surface of the recovery chamber 4 is provided with recovery holes 6;

[0016] The gas heating device 2 comprises a primary heating chamber 7, a heating wire arranged in the primary heating chamber 7 wall, an exhaust fan 8, and a secondary heating chamber 9, and the exhaust fan 8 communicates with the primary heating chamber 7 through the secondary heating chamber 9 to dissipate heat. The cavity 3 communicates with the exhaust fan 8 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com