Cement-doped graded broken stone drying shrinkage detector

A technology of grading crushed stones and detectors, applied in the direction of material inspection products, etc., to achieve the effects of reducing labor intensity, improving test accuracy, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

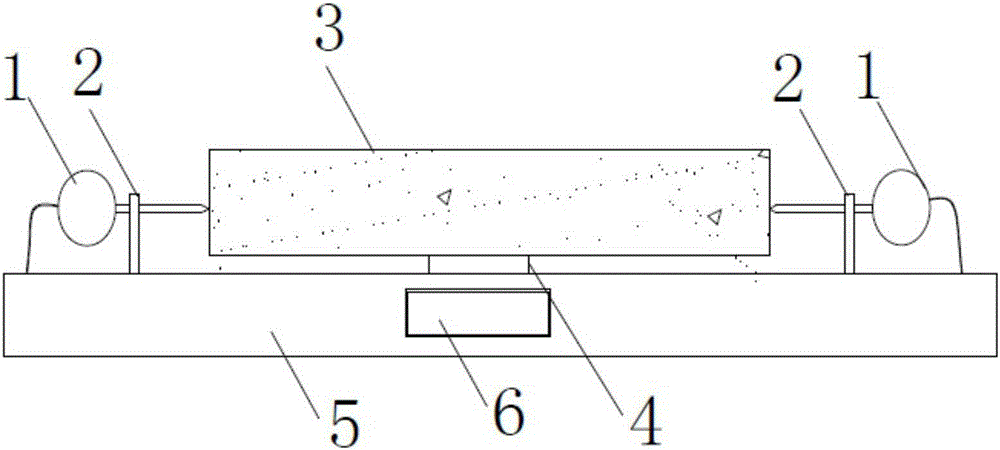

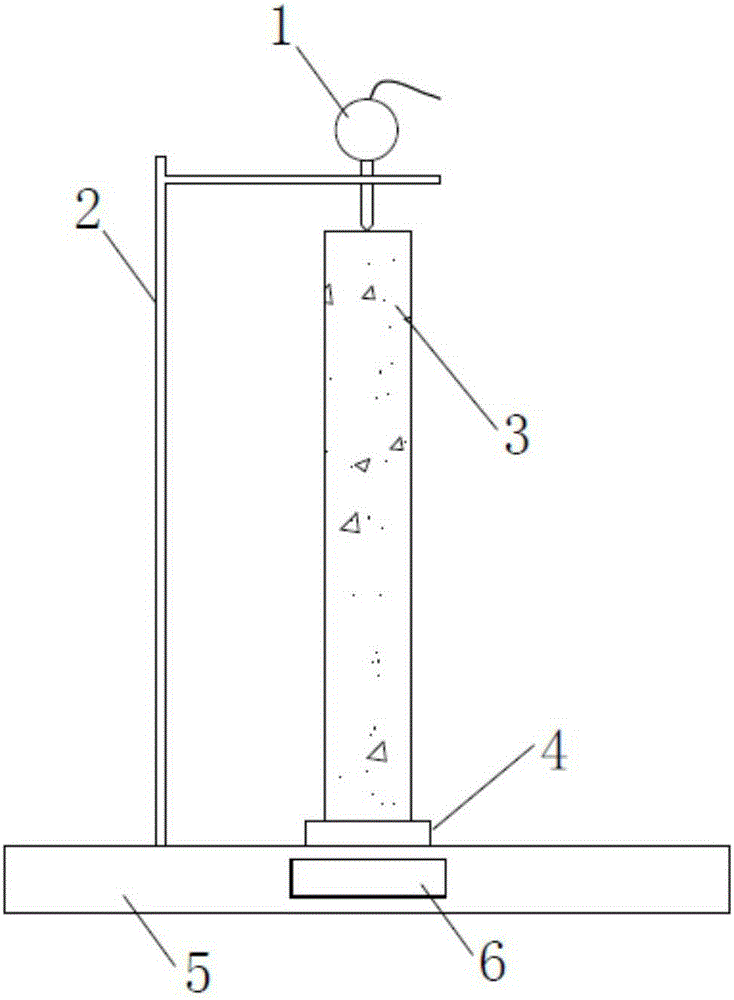

[0032] Specific examples, such as figure 1 , figure 2 Shown:

[0033] 1. Sample preparation: Prepare cement graded crushed stone specimens (such as 5% cement dosage). Maintain under constant temperature (such as 23°C ± 3°C) conditions.

[0034] 2. Assemble the cement-mixed graded crushed stone drying shrinkage detector.

[0035] 3. Place the cured sample above the load cell with the long side parallel to the horizontal direction. Adjust the dial indicator or displacement sensor so that it is closely attached to the test piece and has a certain amount of pre-compression.

[0036] 4. The data processing device collects test data in real time, automatically calculates the sample quality change, drying shrinkage change, and water loss rate, and automatically sounds or the signal light turns on when the sample shrinkage is judged to be basically stable. Display the test data in real time, and automatically draw the relationship curve between the water loss rate and the strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com