Underwater switching device realizing light and heavy assembly load simulation integration of refueling machine of nuclear power plant

A loading and unloading machine, load simulation technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring and other directions, can solve the problem of inability to switch the load mode of light and heavy components, and achieve the effect of high strength and non-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

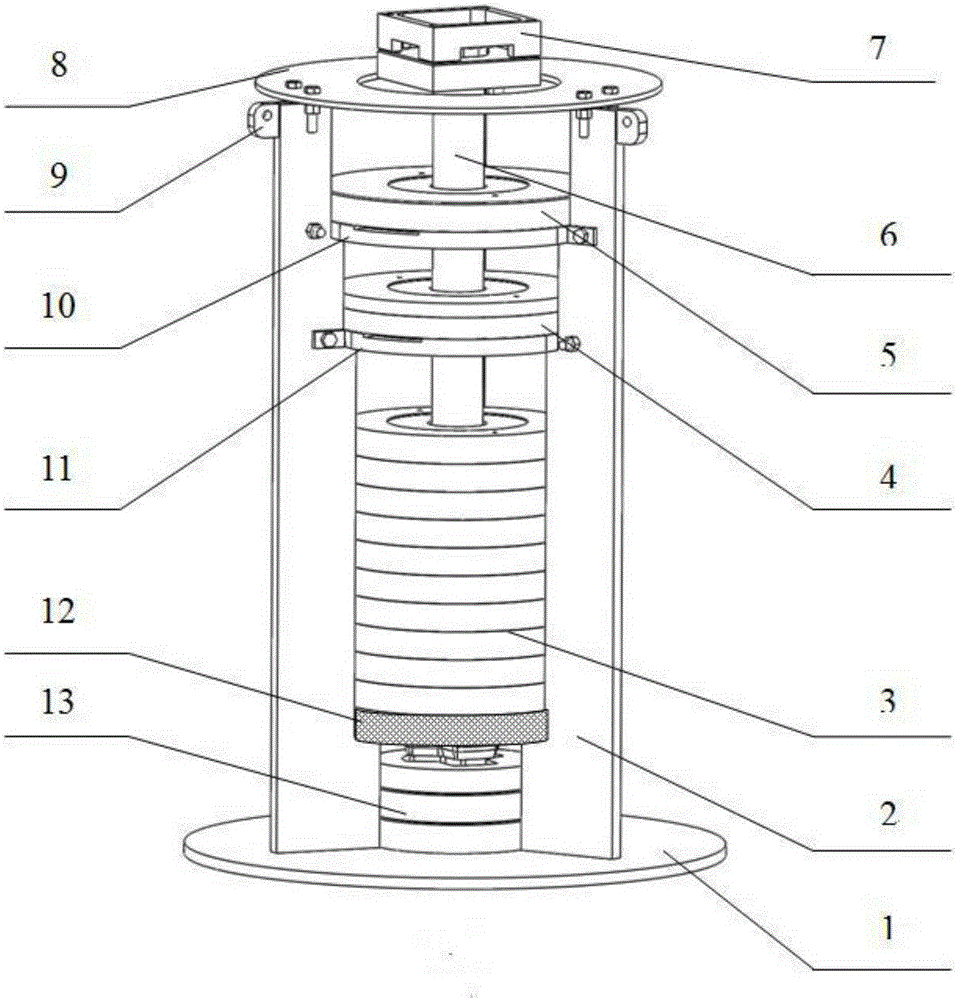

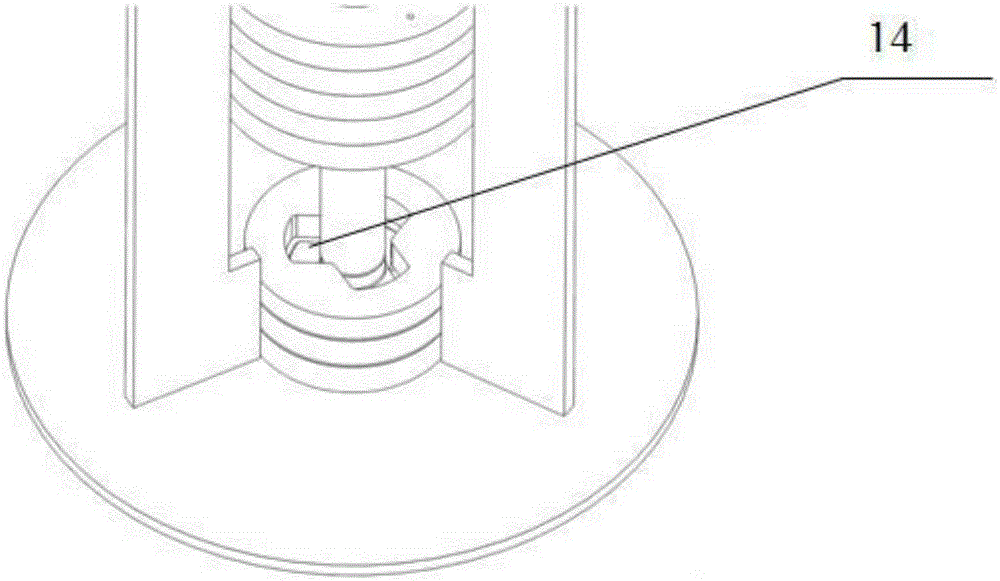

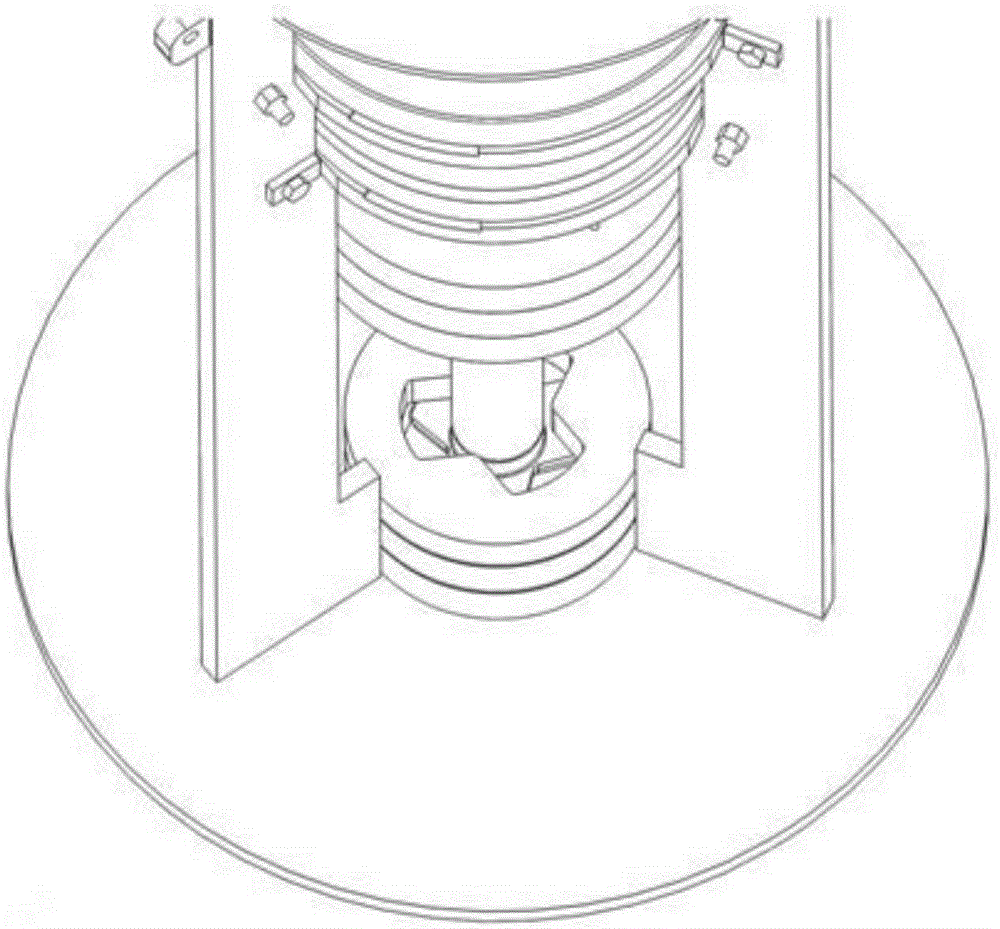

[0023] like figure 1 and figure 2 As shown, an underwater switching device integrating light and heavy component load simulation of a nuclear power plant loading and unloading machine, including a bottom plate 1, a support frame 2, a base weight module 3, an underload counterweight compensation module 4, an overload counterweight compensation module 5, a lifting Rod 6, grab module 7, top plate 8, lifting lug 9, overload counterweight compensation module support ring 10, underload counterweight compensation module support ring 11, base weight module support ring 12, heavy component compensation module 13 and lifting plate 14 .

[0024] The bottom plate 1 is a circular plate structure; the support frame 2 is a plate structure, a total of 3 pieces are evenly distributed at 120°, the lower end is welded to the bottom plate 1, and the inner side of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com