Battery pack active-passive mixed equalization architecture and method thereof

A technology of passive equalization and battery packs, which is applied in electric vehicles, battery circuit devices, secondary battery charging/discharging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Further illustrate the present invention below in conjunction with accompanying drawing and specific embodiment:

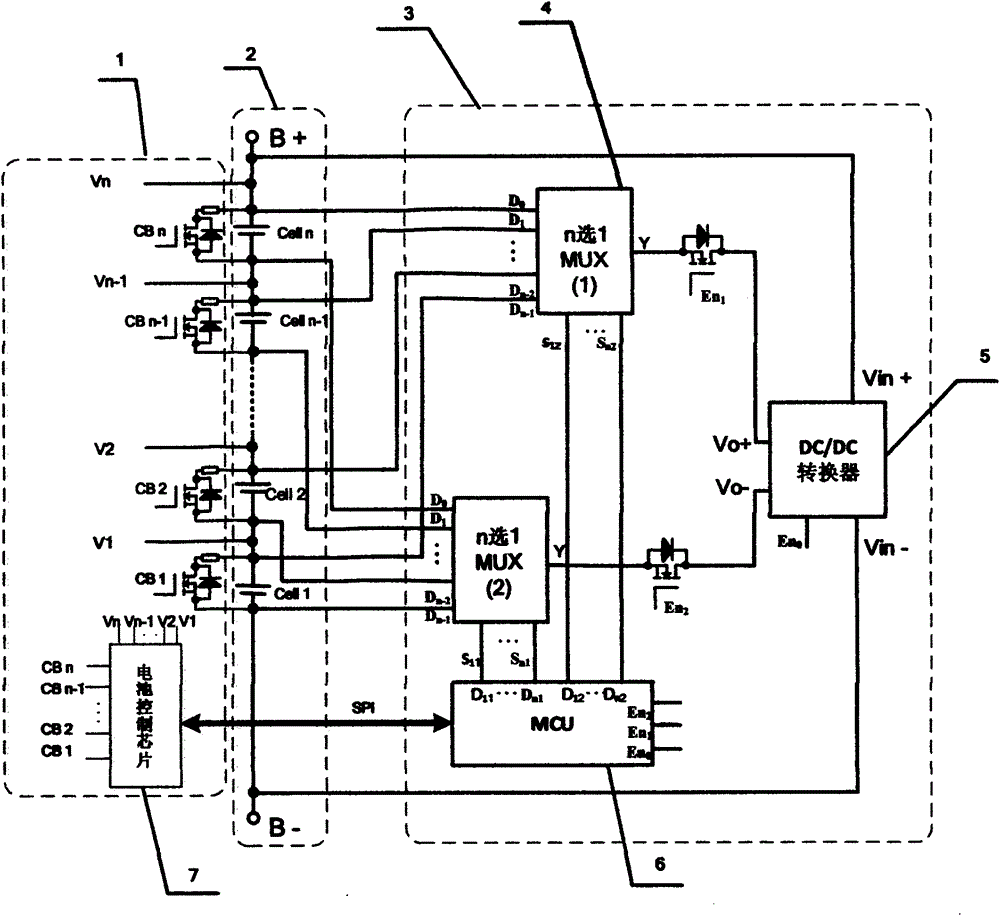

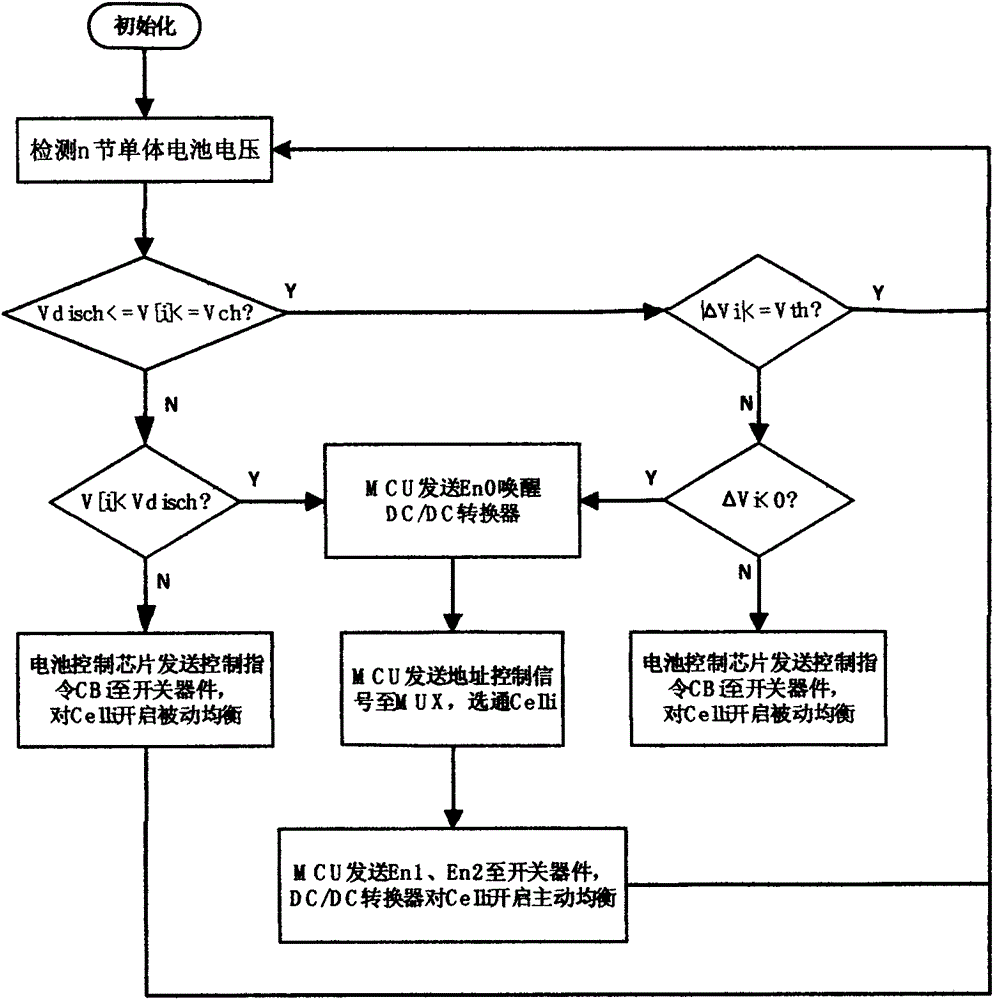

[0010] A battery pack active-passive hybrid equalization architecture and method thereof, characterized in that, a battery pack active-passive hybrid equalization architecture and method thereof, characterized in that it includes a passive equalization module (1), and the passive equalization module includes a battery control A chip (7), n switching devices and n power resistors (connected in parallel with n single cells respectively); includes an active equalization module (3), and the active equalization module includes two multiplexers (4), DC / DC converter (5), main control module MCU (6) and 2 switching devices. The lithium battery pack (2) is composed of n single cells connected in series. The battery control chip is connected to n switching devices respectively, and collects the voltage of n cells; the positive and negative terminals of the lithium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com