A Rotor Axially Interleaved Bearingless Flux Switching Motor

A magnetic flux switching motor and bearingless technology, which is applied in the direction of synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of complex current control, non-current, three-phase current asymmetry, etc., and achieve the effect of solving complex calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

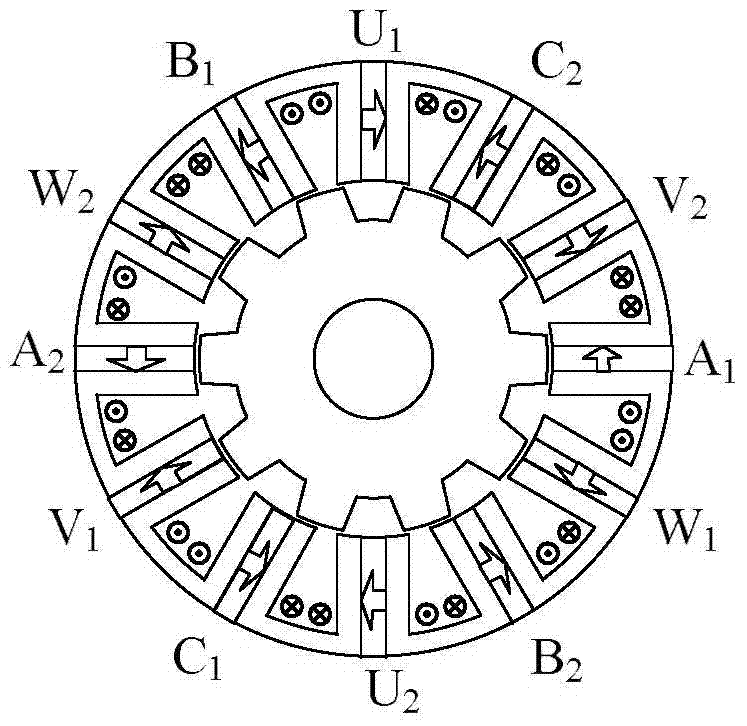

[0040] The invention discloses a rotor axial interlaced bearingless magnetic flux switching motor, which comprises a first stator, a second stator, a first rotor and a second rotor;

[0041] The first stator and the second stator have the same structure, are connected in the middle by superimposing non-magnetic material layers, and the teeth of the two stators are in the same position and their axes coincide;

[0042] The stator teeth of the first stator and the second stator are embedded with permanent magnets, which are magnetized along the circumferential direction, and the magnetization directions of the adjacent permanent magnets in the circumferential direction are opposite;

[0043] The magnetization directions of the permanent magnets in the two stator teeth at the same position of the first stator and the second stator are opposite;

[0044] The first stator and the second stator are provided with the same winding coil on the two stator teeth at the same position;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com