Power supply device used for elevator brake coil

A brake coil and power supply device technology, applied in the field of elevators, can solve problems such as complex control, complex process, and large IGBT switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

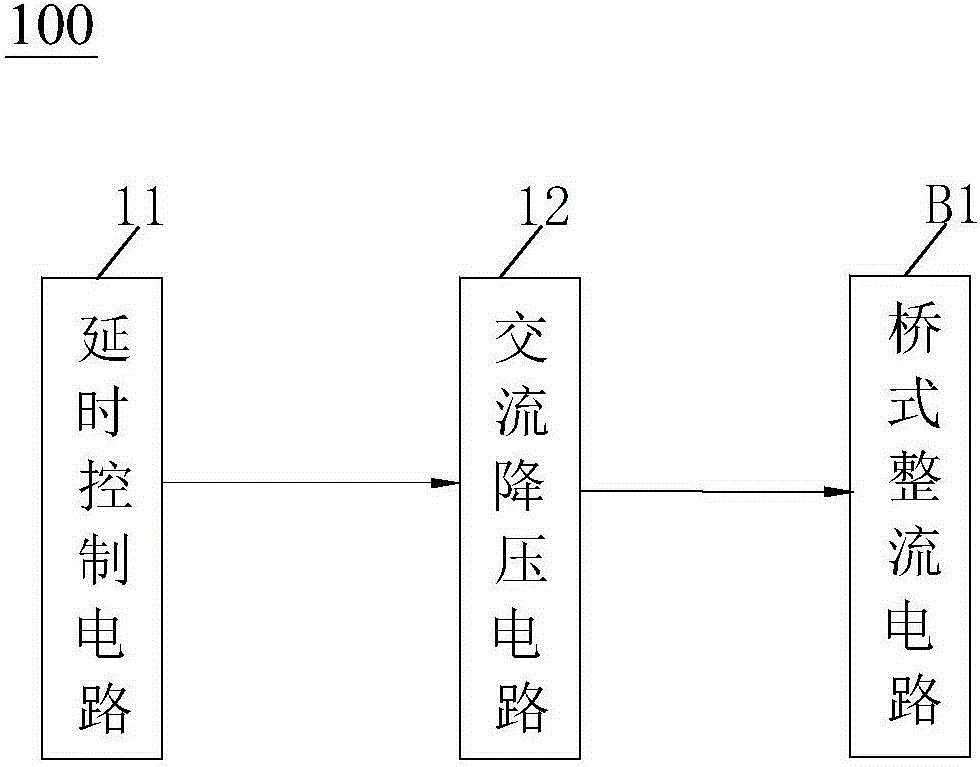

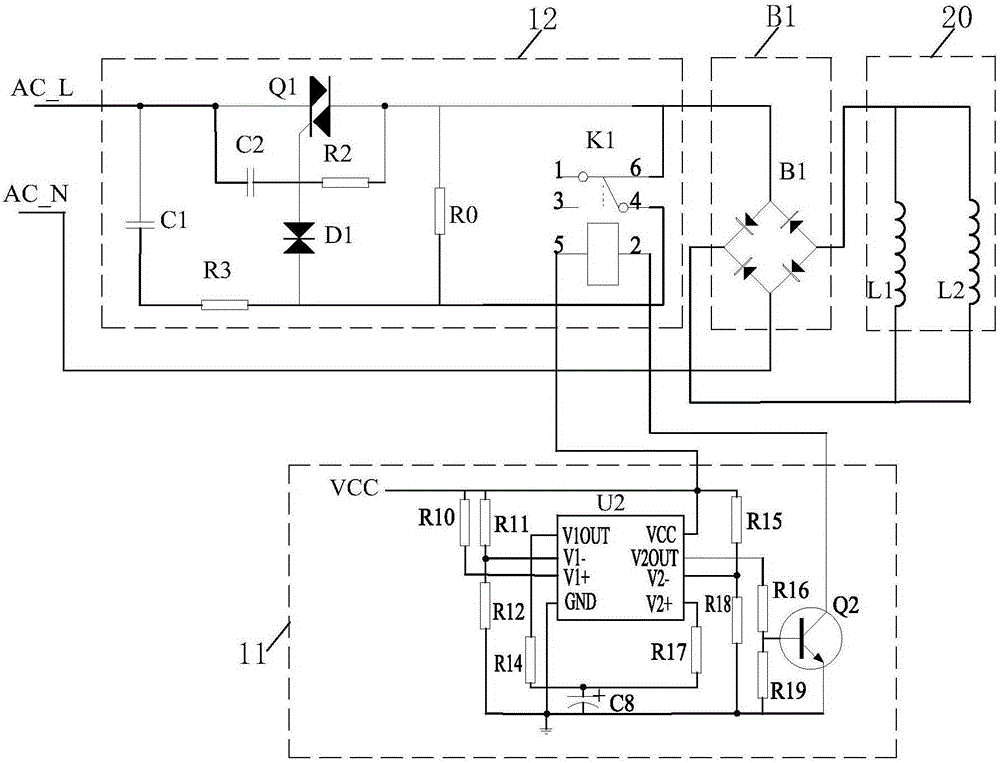

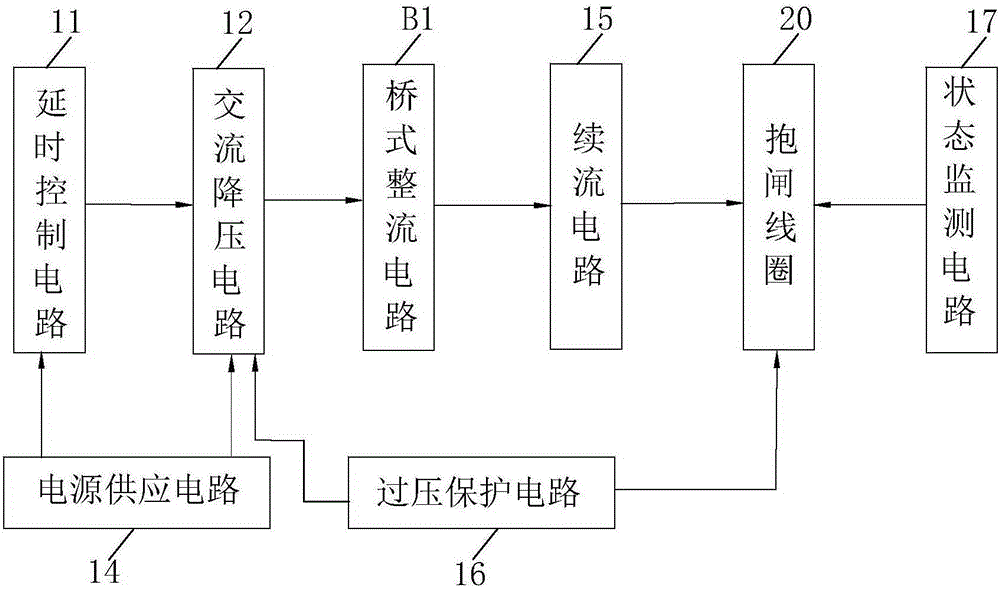

[0026] Please refer to figure 1 , the power supply device 100 used for elevator brake coils in the present invention includes a delay control circuit 11, an AC step-down circuit 12 and a bridge rectifier circuit B1, wherein the delay control circuit 11 is used to respectively Output the first control signal and the second control signal to the AC step-down circuit 12, the output terminal of the AC step-down circuit 12 is connected to the positive input terminal of the bridge rectifier circuit B1, and the negative input terminal of the bridge rectifier circuit B1 is connected to the mains The neutral line AC_N is connected, and the output end of the bridge rectifier circuit B1 is connected to the brake coil 20 . Specifically, such as figure 2 As shown, the brake coil 20 is represented by an inductance L1 and an inductan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com