Method and corresponding device for coupling a shaft of an electric motor with a wheel shaft of an electrically powered or hybrid motor vehicle

A technology for hybrid vehicles and electric motors, applied in hybrid vehicles, engine-driven traction, electric vehicles, etc., can solve problems such as vibration, speed increase, and electric motor speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

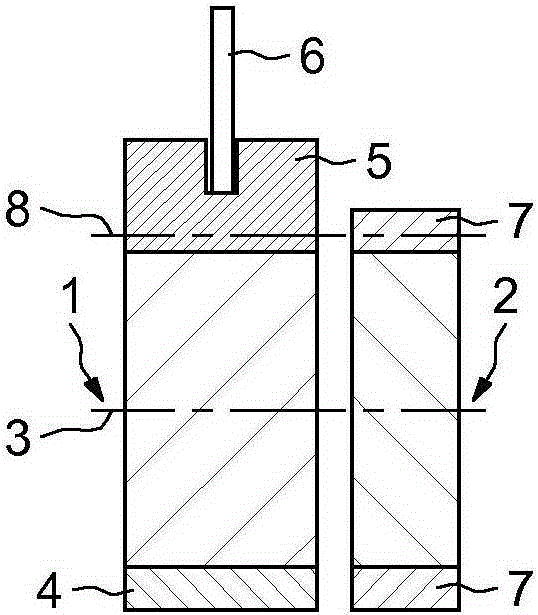

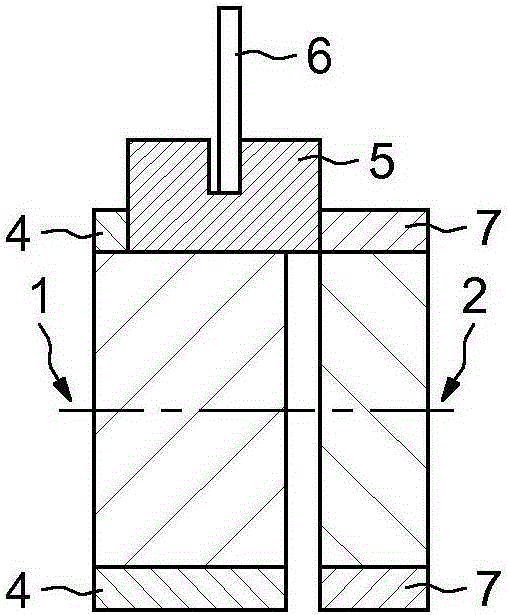

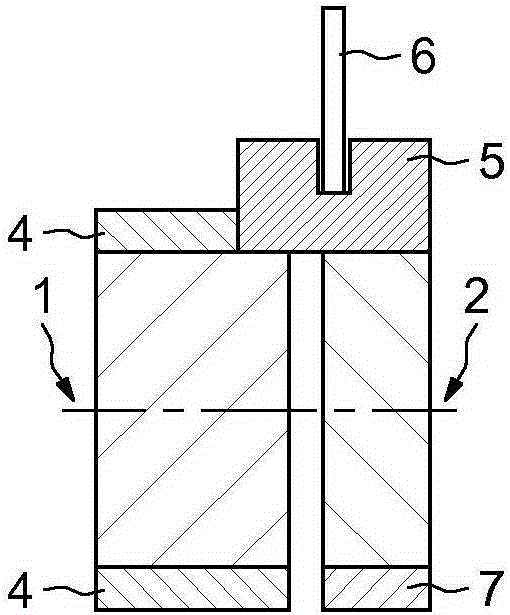

[0041] Figure 1a A first pinion 1 , for example connected to the shaft of an electric motor, and a second pinion 2 , for example connected to the shaft of a wheel, are shown. The first pinion 1 and the second pinion 2 are shown from the front, thus the axis of rotation 3 is shown with dashed lines. The pinion 1 comprises a set of teeth, one of which 4 is visible. A sliding gear 5 enabling shaft coupling is connected to the teeth of the pinion 1 . The sliding gear 5 can be moved in translation by the action of the fork 6 .

[0042] The second pinion is equipped with a plurality of teeth 7, and in Figure 1a In the case shown, these teeth can have a rotational movement only linked to the rotational movement of the wheel.

[0043] Figure 2ashows another view of pinions 1 and 2, which is the same as Figure 1a Corresponds to the sectional plan view with reference number 8 in . The sliding gear 5 comprises teeth 5 coupled with the teeth 4 of the pinion 1 . In this figure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com