Retort pouch of fried pork and processing technology of retort pouch

A technology of processing technology and conditioning package, which is applied in the field of small fried meat conditioning package and its processing technology, can solve the problems of high water content, affecting the appearance, and different degrees of thickening of the conditioning package, so as to increase the adsorption capacity and realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

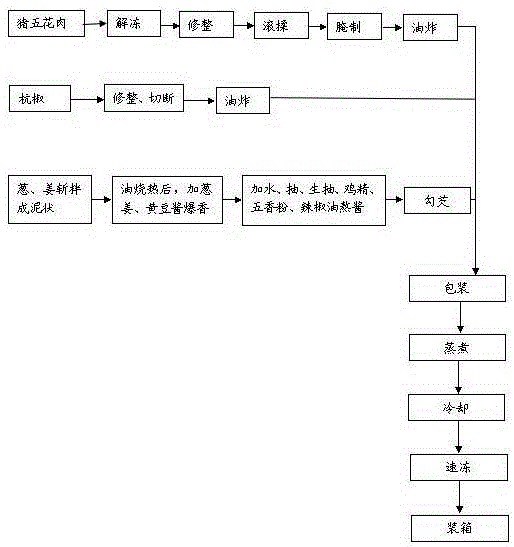

Method used

Image

Examples

Embodiment

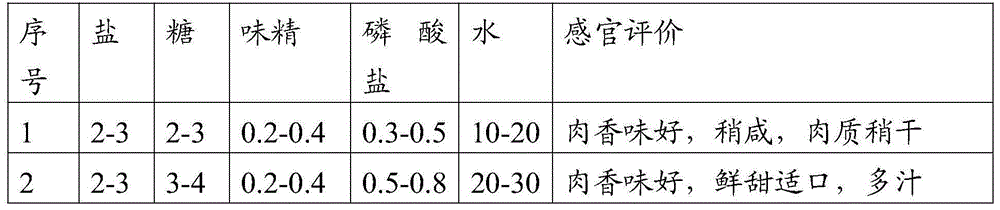

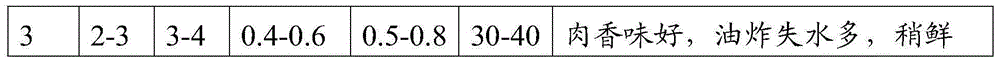

[0050] The conditioning package is prepared from the following raw materials and parts by weight: 100-120 parts of pork belly, 2-3 parts of salt, 3-4 parts of sugar, 0.2-0.4 parts of monosodium glutamate, 0.5-0.8 parts of sodium tripolyphosphate, water 90-130 parts, salad oil 100-120 parts, soybean paste 10-15 parts, soy sauce 5-7 parts, dark soy sauce 5-7 parts, chicken essence 2-3 parts, chili oil 5-8 parts, carrageenan 0.5- 0.8 parts, 4-6 parts of onion, 4-6 parts of ginger, 2-3 parts of five-spice powder, 6-8 parts of modified starch, 20-25 parts of pepper, and 20-25 parts of green pepper.

[0051] Preferably: 100 parts of pork belly, 2 parts of salt, 3 parts of sugar, 0.2 parts of monosodium glutamate, 0.5 parts of sodium tripolyphosphate, 90 parts of water, 100 parts of salad oil, 10 parts of soybean paste, 5 parts of light soy sauce, 5 parts of dark soy sauce, 2 parts of chicken essence, 5 parts of chili oil, 0.5 parts of carrageenan, 4 parts of onion, 4 parts of ginger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com