Electric steamer

A technology of electric steamer and liner, which is applied in the field of electric steamer, can solve the problems of easy failure of sealant, easy peeling of sealant, unintuitive cooking work, etc., and achieves easy cleaning and replacement of parts, good airtightness and perspective , The effect of facilitating internal working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

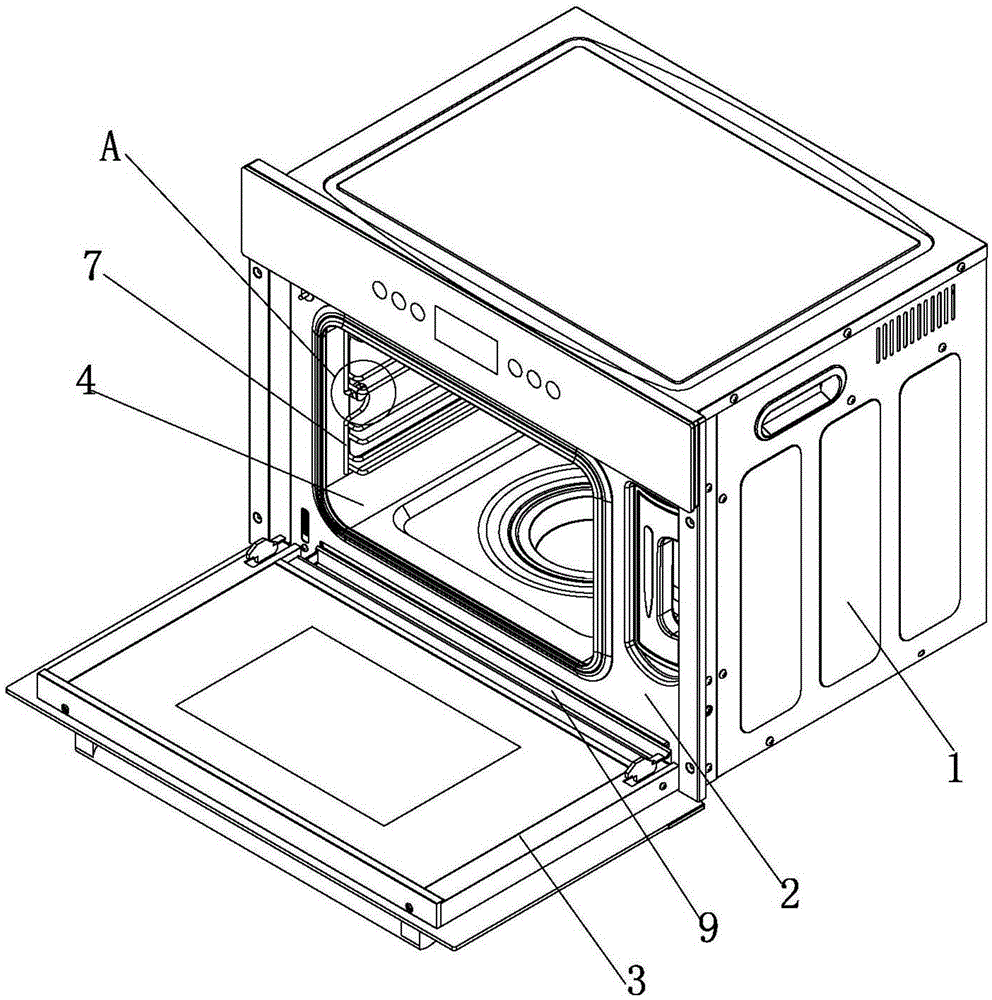

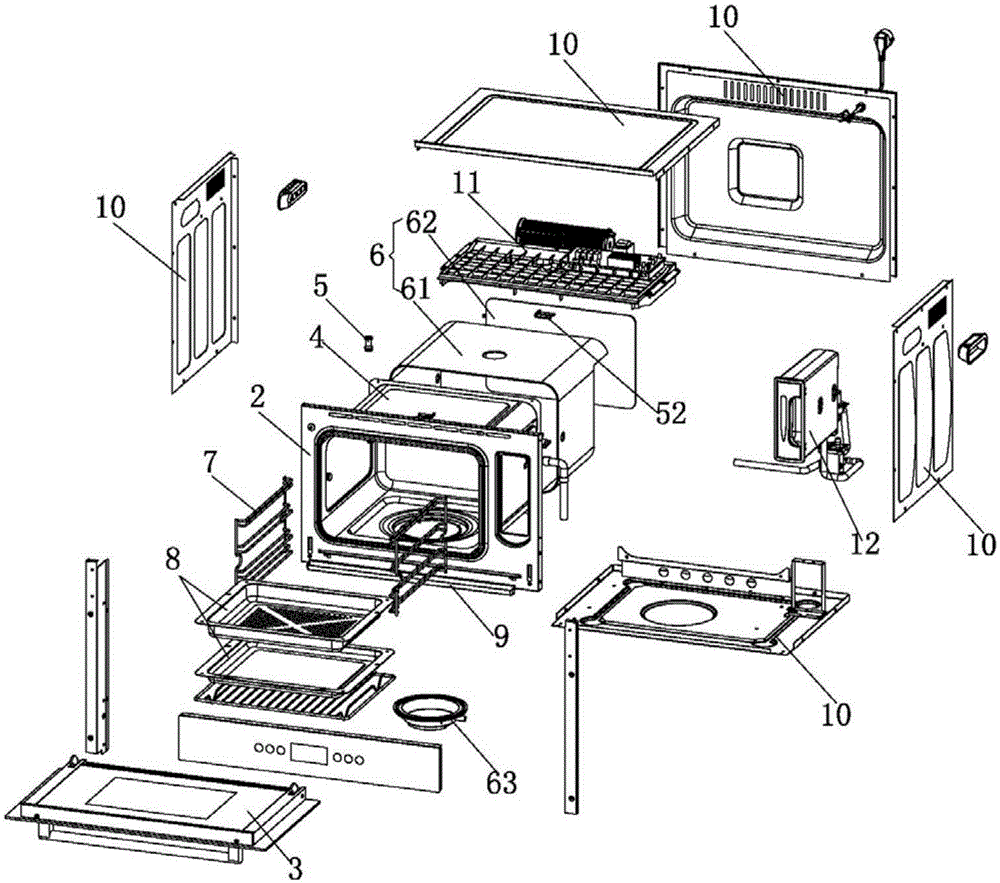

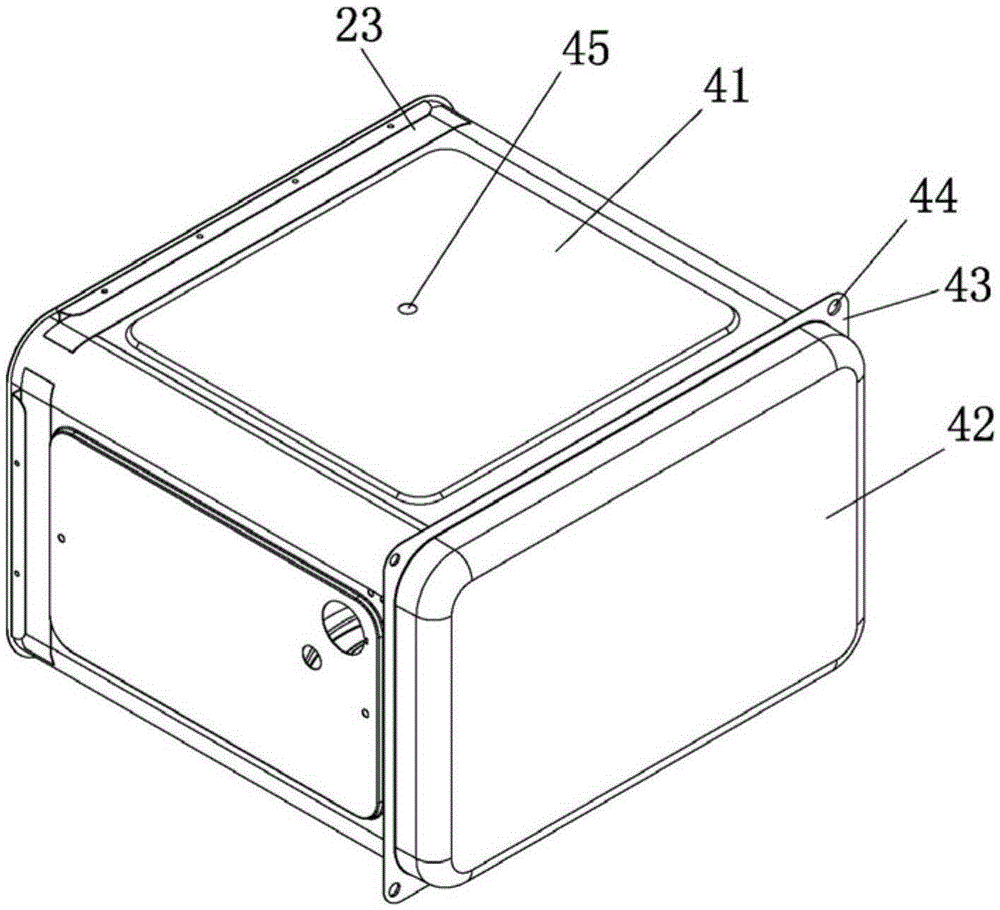

[0047] Please refer to the attached figure 1 to attach Figure 20 As shown, the present invention is an electric steamer, which consists of an electric steamer housing 1, a front panel 2, a sliding door 3, an inner tank 4, a pressure relief mechanism 5, a heating mechanism 6, a hanger 7, a tray 8 and a connecting rod. Several parts such as water box 9 form.

[0048] Wherein, the electric steamer casing 1 is assembled from several plates 10, and systems such as an exhaust system 11 and a water supply system 12 are also accommodated therein. Since the above-mentioned systems have nothing to do with the invention purpose of this creation, and are prior art , so it will not be repeated here.

[0049]The front panel 2 is installed on the front end of the electric steamer casing 1 . The sliding door 3 is pivotally connected to the electric steamer casing 1 through a pair of hinges 14, and its top end can be turned up and down. The liner 4 is installed in the casing 1 of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com