A Matrix Type Ammonia Injection Grille with Mixing Device

A technology of mixing device and ammonia spray grid, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of accelerated wear and corrosion, large flue gas resistance, long mixing distance, etc., so as to improve anti-blocking and wear resistance, reduce smoke resistance, reduce the effect of mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

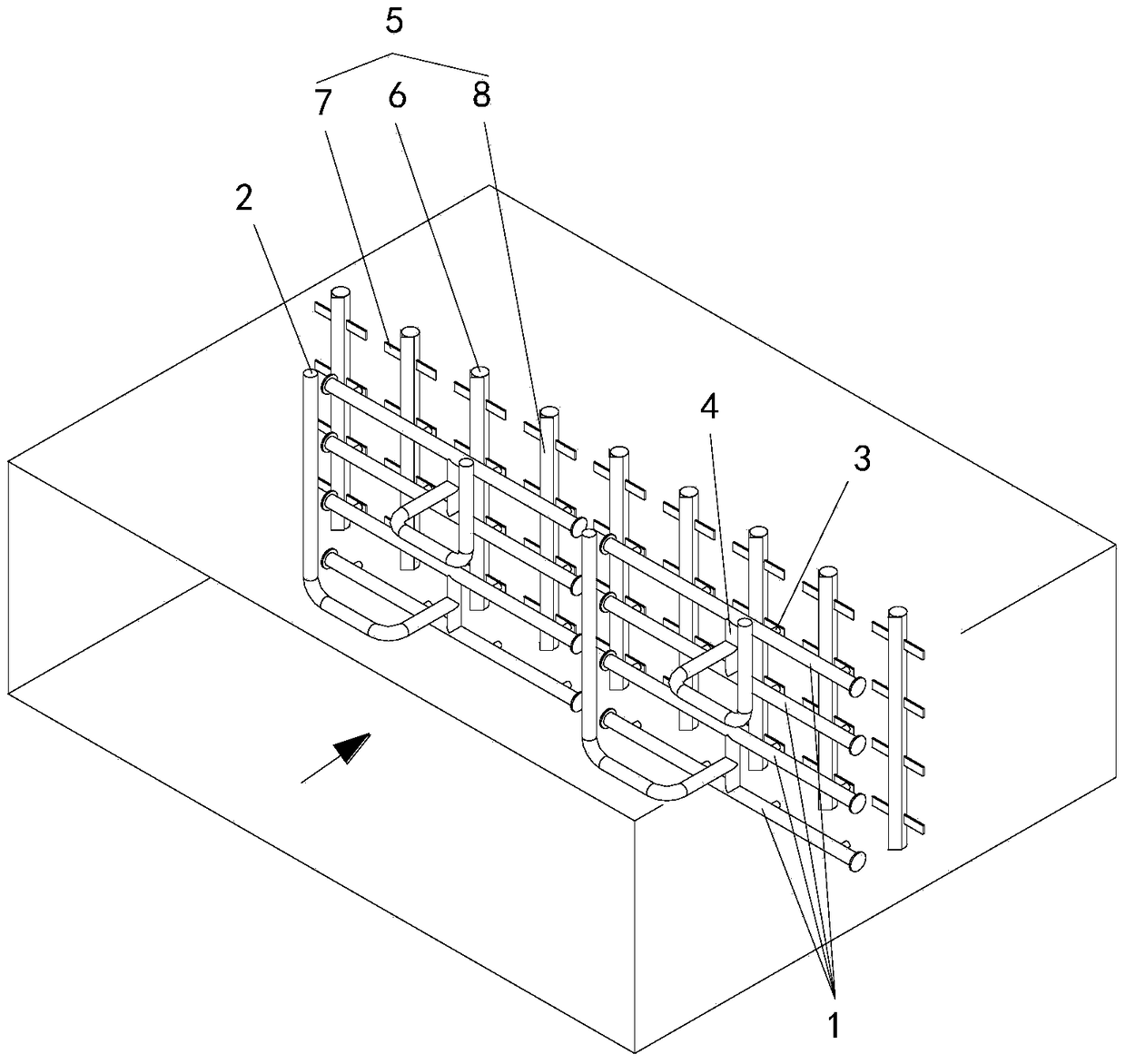

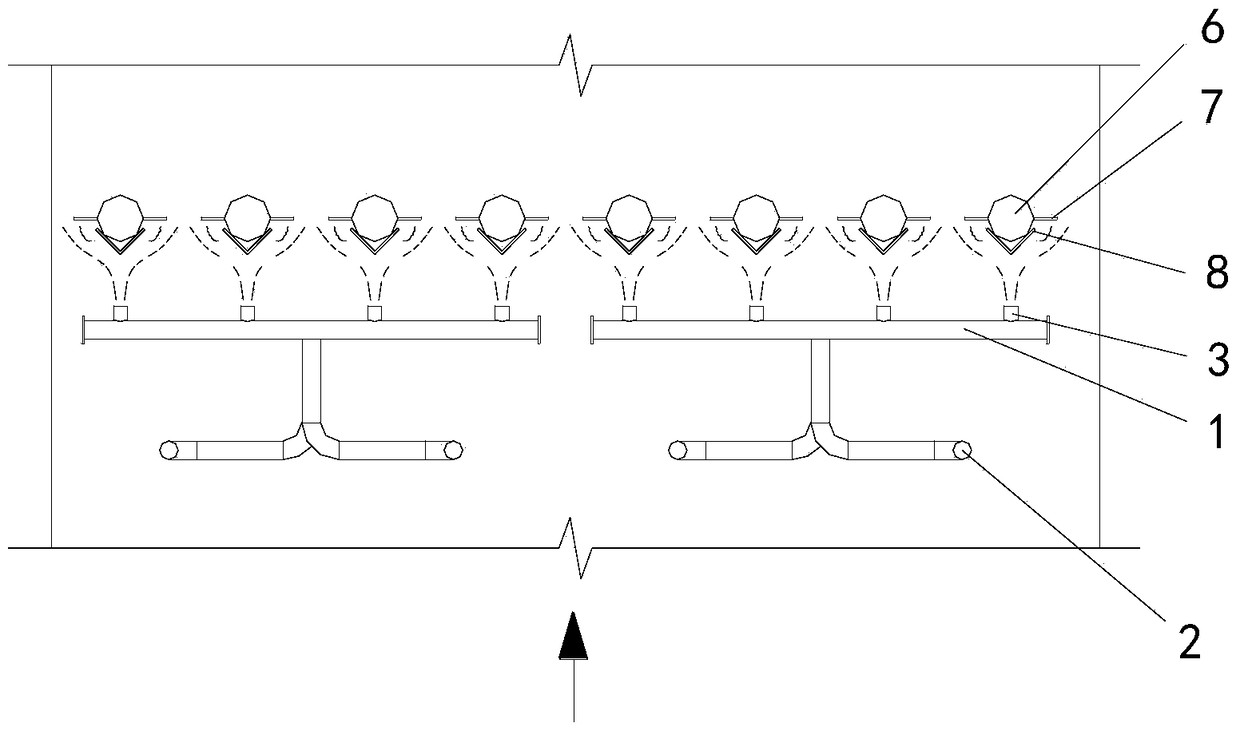

[0016] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, a matrix-type ammonia injection grid with a mixing device includes an air injection pipe 1, an air intake pipe 2 and a nozzle 3, the air injection pipes 1 are arranged at equal intervals and arranged in a matrix, and 1 to 10 air injection pipes 1 form an injection unit, the middle part of the air injection pipe 1 of each injection unit is connected together through the connecting pipe 4, and the connecting pipe 4 is provided with an air intake pipe 2; each air injection pipe 1 is provided with a nozzle 3; more than one mixing The device 5 and the mixing device 5 are respectively arranged opposite to each row of nozzles 3 .

[0017] The mixing device 5 includes a spoiler 6 and a spoiler 7, the spoiler 7 is fixed on the spoiler 6, the spoiler 7 is arranged in parallel with the jet tube 1, and each jet tube 1 corresponds to a spoiler 7. Each spoiler tube 6 is provided with an anti-wear deflector 8...

Embodiment 2

[0018] Embodiment 2 of the present invention: as figure 1 and figure 2 As shown, a matrix-type ammonia injection grid with a mixing device includes an air injection pipe 1, an air intake pipe 2 and a nozzle 3, the air injection pipes 1 are arranged at equal intervals and arranged in a matrix, and 1 to 10 air injection pipes 1 form an injection unit, the middle part of the jet pipe 1 of each jet unit is connected together by a connecting pipe 4, the connecting pipe 4 is provided with an air intake pipe 2; each jet pipe 1 is provided with a nozzle 3; more than one mixing The device 5 and the mixing device 5 are respectively arranged opposite to each row of nozzles 3 .

[0019] The mixing device 5 includes a spoiler 6 and a spoiler 7, the spoiler 7 is fixed on the spoiler 6, the spoiler 7 is arranged in parallel with the jet tube 1, and each jet tube 1 corresponds to a spoiler 7. Each spoiler tube 6 is provided with an anti-wear deflector 8 , and the cross-sectional shape of t...

Embodiment 3

[0020] Embodiment 3 of the present invention: as figure 1 and figure 2 As shown, a matrix-type ammonia injection grid with a mixing device includes an air injection pipe 1, an air intake pipe 2 and a nozzle 3, the air injection pipes 1 are arranged at equal intervals and arranged in a matrix, and 1 to 10 air injection pipes 1 form an injection unit, the middle part of the air injection pipe 1 of each injection unit is connected together through the connecting pipe 4, and the connecting pipe 4 is provided with an air intake pipe 2; each air injection pipe 1 is provided with a nozzle 3; more than one mixing The device 5 and the mixing device 5 are respectively arranged opposite to each row of nozzles 3 .

[0021] The mixing device 5 includes a spoiler 6 and a spoiler 7, the spoiler 7 is fixed on the spoiler 6, the spoiler 7 is arranged in parallel with the jet tube 1, and each jet tube 1 corresponds to a spoiler 7. Each spoiler tube 6 is provided with an anti-wear deflector 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com