Soil pulverizer

A soil crusher and bottom plate technology, which is applied to soil block crushers, agricultural machinery and implements, and grain processing, can solve problems such as increased production costs, unreasonable structures, time-consuming and labor-intensive, etc., to improve work efficiency, The effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

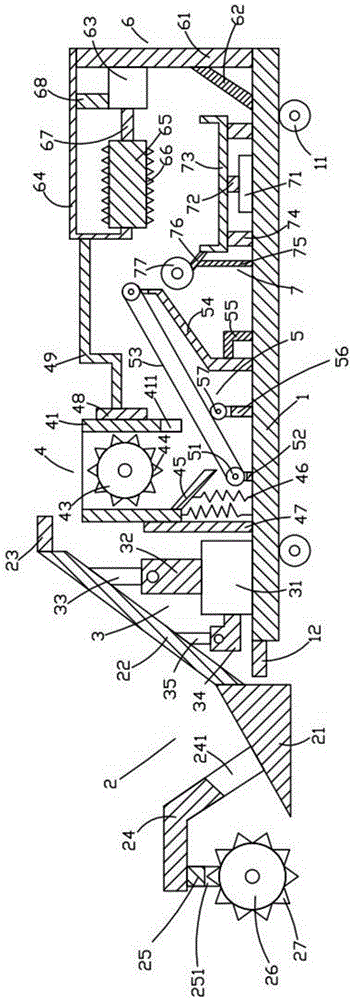

[0019] Such as figure 1 As shown, the earth crusher of the present invention includes a bottom plate 1, a hoeing device 2 located on the left side of the bottom plate 1, a first cylinder device 3 located above the bottom plate 1, and a pulverizer located on the right side of the first cylinder device 3. The device 4 , the conveyor belt device 5 located below the crushing device 4 , the motor device 6 located on the right side of the conveyor belt device 5 and the second cylinder device 7 located below the motor device 6 .

[0020] Such as figure 1 As shown, the bottom plate 1 is in the shape of a cuboid, and the bottom plate 1 is placed horizontally. The bottom plate 1 is provided with a roller 11 and a first positioning rod 12 on the left side of the roller 11 . There are two rollers 11 located on the left and right sides respectively, the rollers 11 are cylindrical, the rollers 11 are placed horizontally, and the rollers 11 are arranged on the lower surface of the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com