Stamping outer ring bearing detector

A stamping outer ring and detection machine technology, applied in sorting and other directions, can solve the problems of unfavorable product detection data analysis, high labor cost, large manual intervention, etc., to shorten the product detection cycle, facilitate disassembly and assembly, and improve maintenance speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

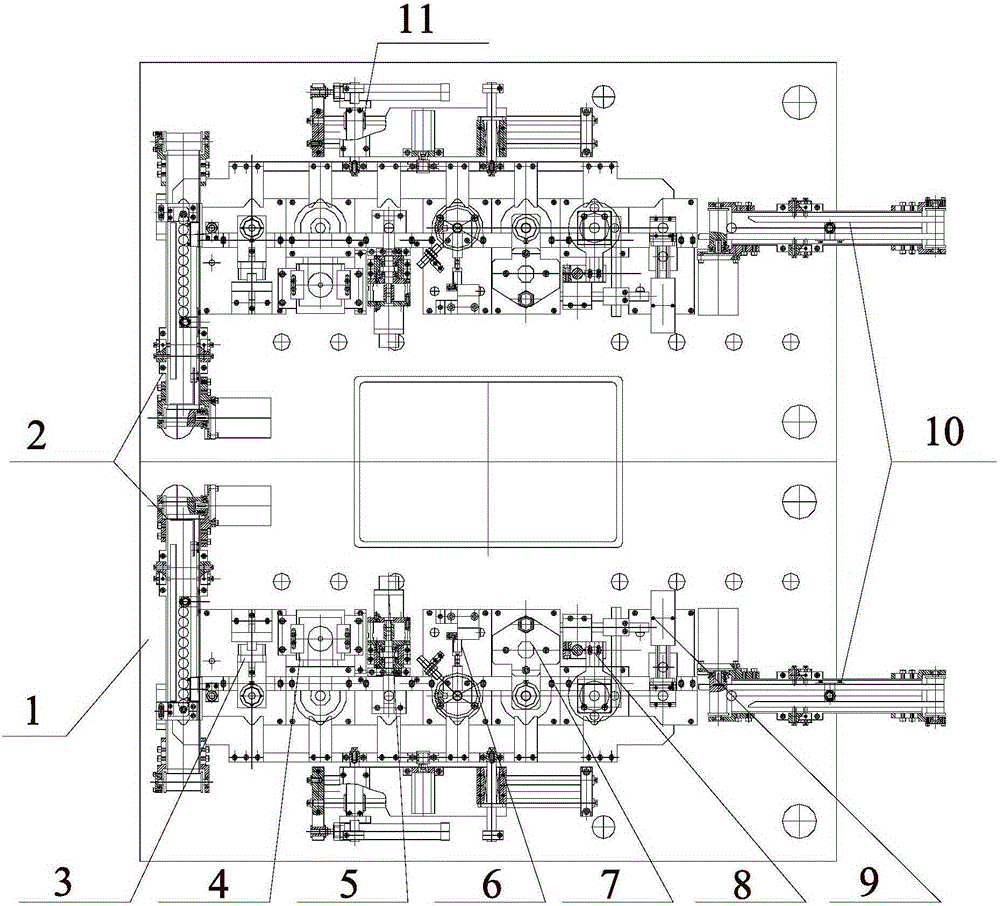

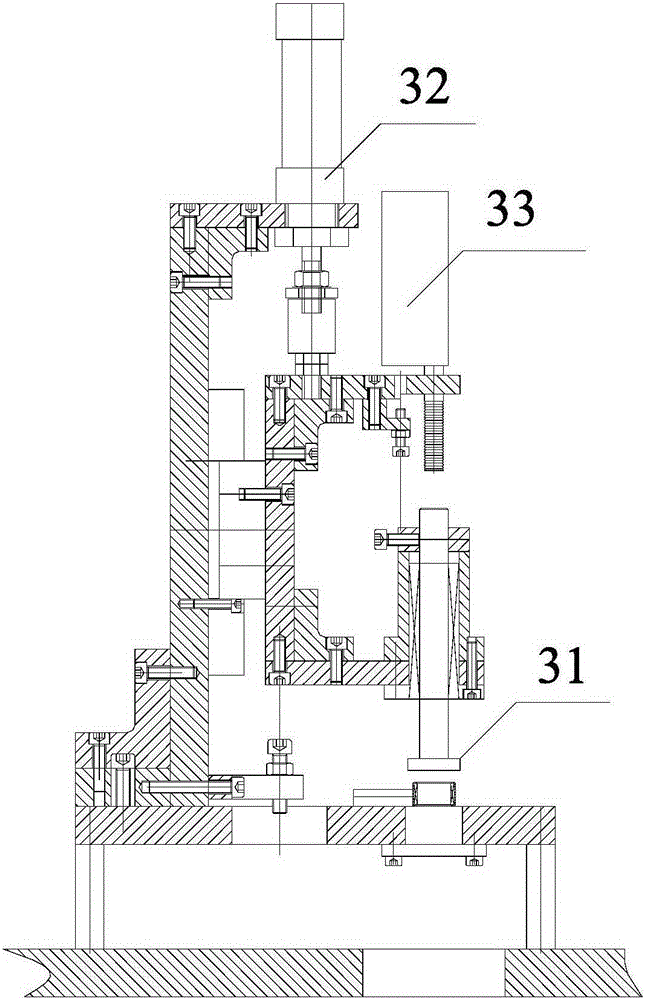

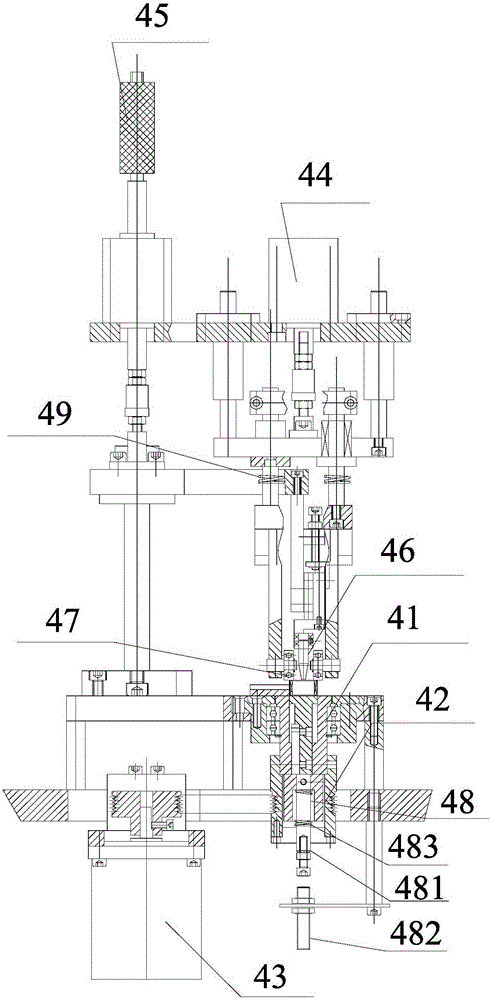

[0052] see figure 1 , which is an embodiment of the present invention, provides a stamped outer ring bearing inspection machine, which includes a bracket 1, and a feeding conveyor belt 2 for conveying bearings is arranged in turn on the frame 1 from left to right to detect the height of the bearing Height measurement station 3, eddy current inspection station 4 for bearing end face and R angle crack detection, turning station 5 for turning the bearing over, flexibility inspection station 6 for bearing flexibility...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com