Cylinder welding process

A welding process and cylinder technology, which is applied in the welding process field of high-strength steel thick plates, can solve the problems of high labor intensity, difficulty in guaranteeing welding quality, labor and time-consuming, etc., and achieve the effect of saving welding materials and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

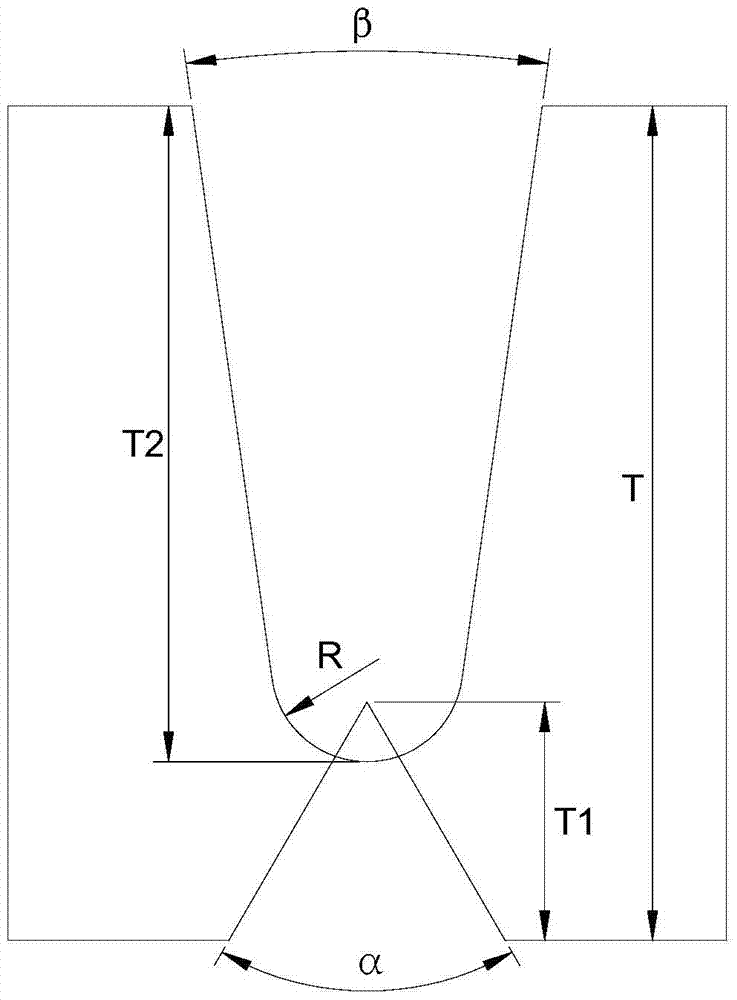

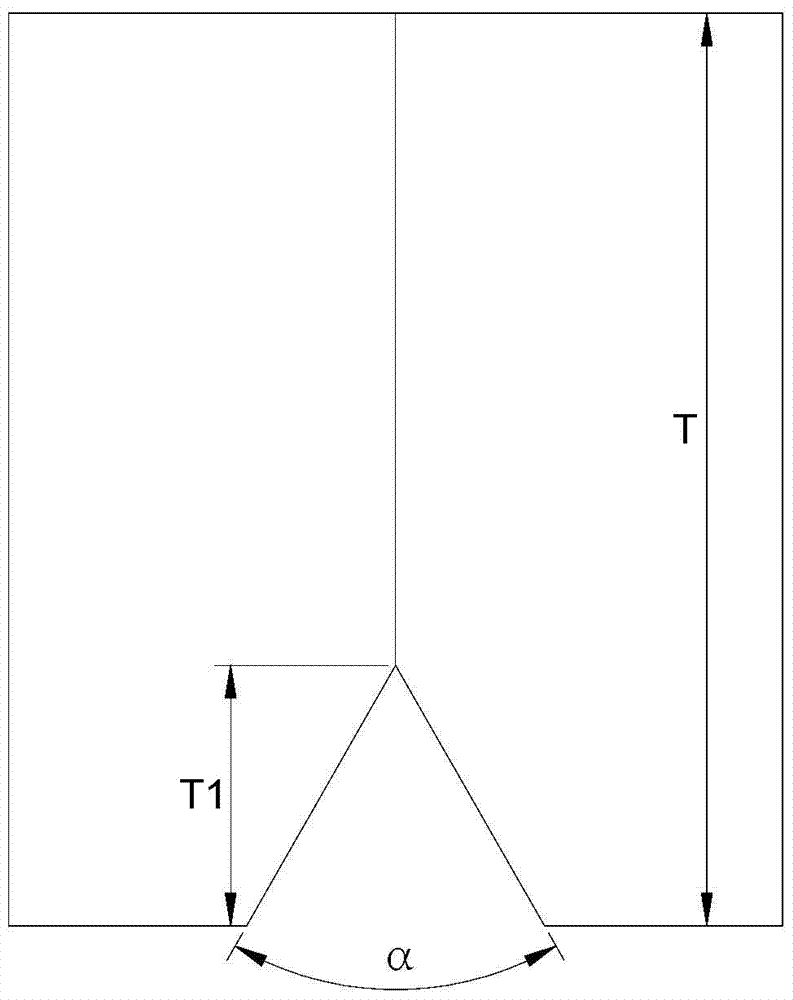

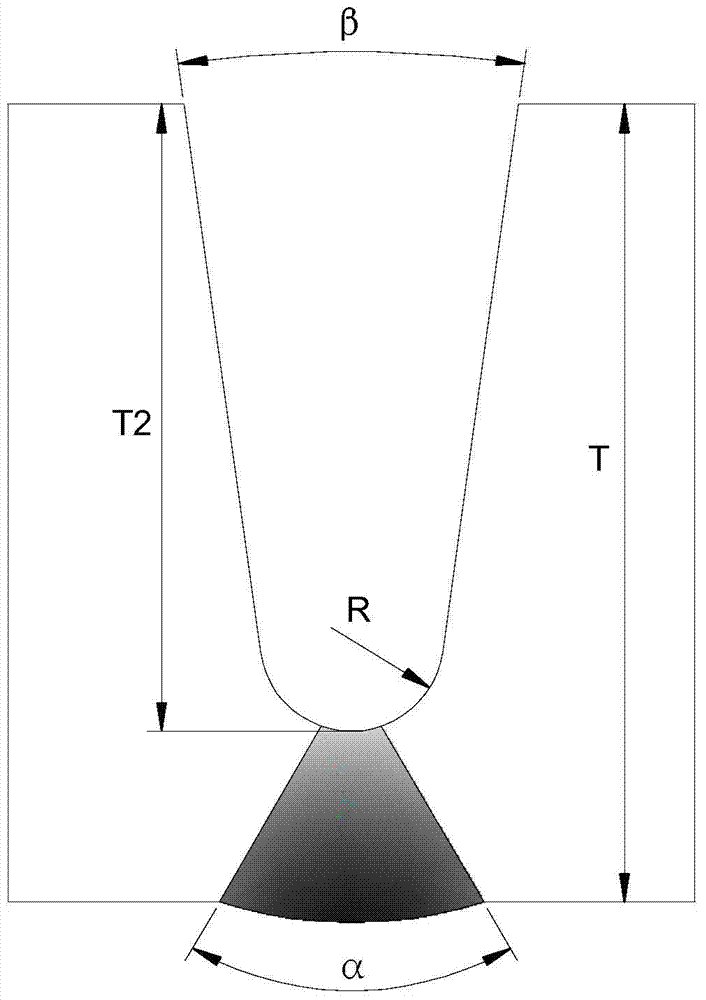

[0040] first reference figure 1 as shown, figure 1 A schematic diagram of a groove structure formed in a cylinder welding process according to an embodiment of the present invention is disclosed. Such as figure 1 As shown, the groove is a narrow gap U-shaped groove, and the groove can be roughly divided into two parts: the outer groove and the inner groove. external bevel figure 1 In the upward part of the middle opening, the outer bevel is a U-shaped bevel with a slightly inclined side wall and an open opening, and the root of the outer bevel is a rounded corner. internal groove figure 1 Inverted V-groove. After the internal groove and the external groove are all processed and formed, the root of the internal groove overlaps with the external groove, so the internal groove is not a complete inverted V shape, but an inverted V shape with the tip part missing. The inner groove meets the outer groove.

[0041] continue to refer figure 1 as shown, figure 1 The letters in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com