Multi-specification high stability pressure cutting system

A highly stable and multi-standard technology, applied in metal processing, etc., can solve problems such as insufficient uniformity and stability, unsatisfactory positioning effect, and synchronization constraints of oil cylinders, so as to reduce the cost of pressing and cutting, balance pressure, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and working process, but it is not a limitation to the protection scope of the present invention.

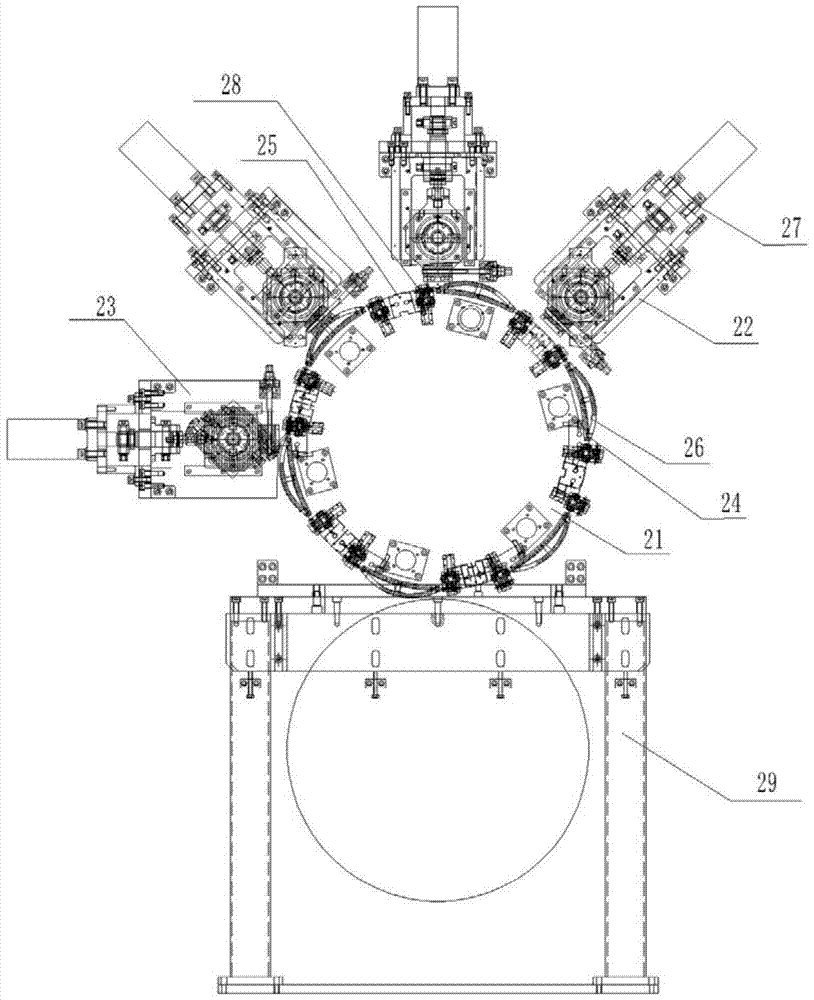

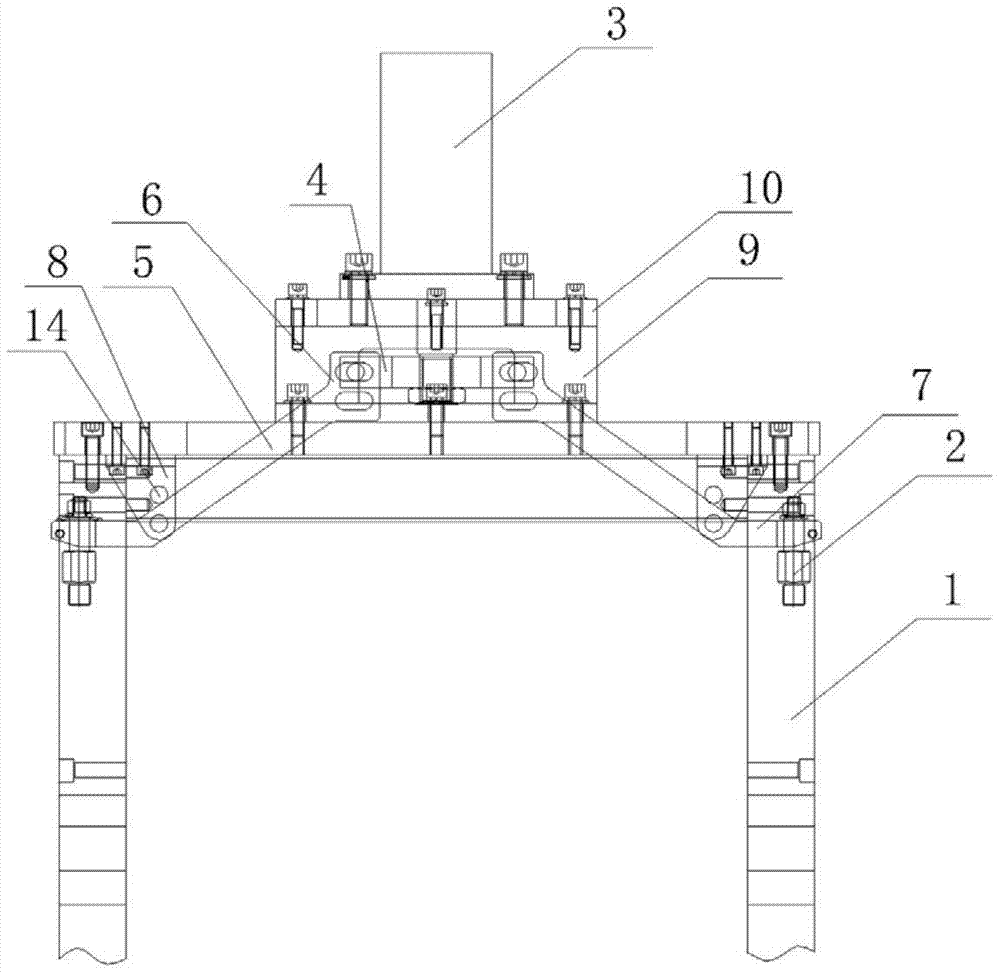

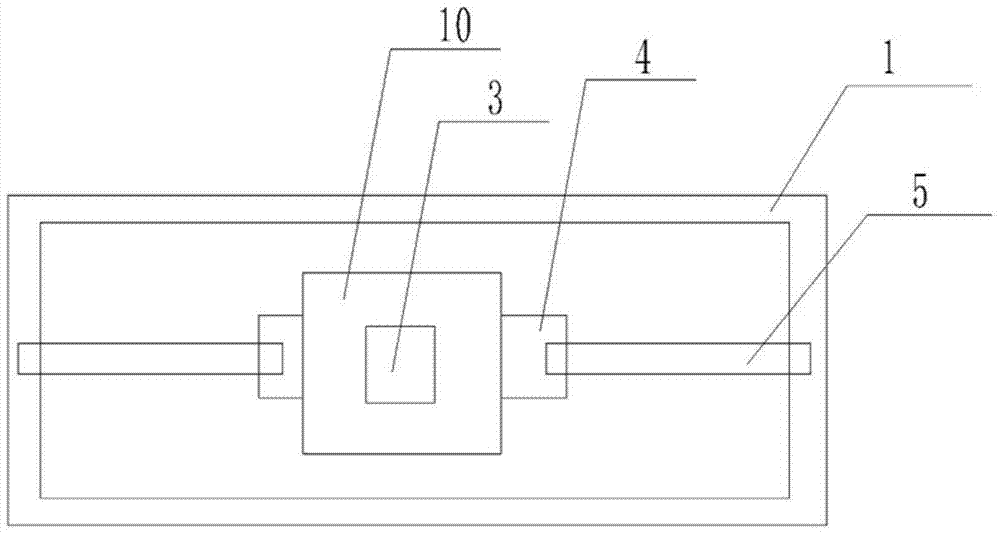

[0029] like Figure 1-5 As shown, a multi-standard high-stable pressure-cutting system includes a runner 21, a product output device 29, 6 pressing and cutting pads 25 and 6 positioning mechanisms evenly arranged on the running wheel 21, and matching pressing and cutting pads. The cutting device 23 and the pressing device 22 of the block 25, the top of the pressing device 22 is provided with a lever pressing mechanism 27, and the lever pressing mechanism 27 includes a support frame 1, a pressure member 2 arranged on the support frame 1 and a pressure member 2 arranged on the support frame 1. The hydraulic cylinder 3 on the pressure piece 2, the hydraulic cylinder 3 is placed upside down in the middle of the support frame 1, a lifting block 4 is fixed on the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com