Composite material buoyancy tank glued by wood-plastic foaming board, PIN core material and foaming board

A technology of wood-plastic foaming and foaming boards, applied in electronic equipment, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of high price, unfavorable popularization and promotion, etc., so as to prolong the service life and improve safety The service life, the effect of protecting the safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

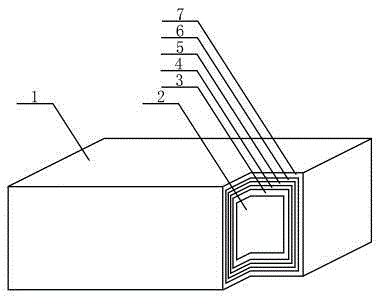

Embodiment 1

[0030] In fish ponds, reservoirs, lakes and other waters involving agriculture and fishery where the water depth exceeds 3 meters or is not suitable for piling construction, it is necessary to install a buoyancy box with a low cost and can provide a certain buoyancy to carry the weight of the floating photovoltaic power generation device on the water surface . Divide the PVC foam board according to the design drawings, glue the PVC foam board with waterproof glue to form a foam board buoyancy box, fill the inside of the foam board buoyancy box with EPS buoyancy foam, and use waterproof double-layer foam on the outside of the foam board buoyancy box The surface adhesive tape layer is glued to the PIN structure core material layer, and the waterproof glue is used to bond the glued PIN structure core material layer, wood-plastic foam board layer and glass fiber wrapping layer sequentially from the inside to the outside to form agriculture and fishery. Composite buoyancy tanks use...

Embodiment 2

[0032]In fish ponds, reservoirs, lakes and other waters involving agriculture and fishery where the water depth exceeds 3 meters or is not suitable for piling construction, it is necessary to install a buoyancy box with a low cost and can provide a certain buoyancy to carry the weight of the floating photovoltaic power generation device on the water surface . Divide the PP foam board according to the design drawings, bond and glue the PP foam board with waterproof glue to form a foam board buoyancy tank, fill the inside of the foam board buoyancy tank with EPS buoyancy foam, and use waterproof double-layer foam on the outside of the foam board buoyancy tank The surface adhesive tape layer is glued to the PIN structure core material layer, and the waterproof glue is used to bond the glued PIN structure core material layer, wood-plastic foam board layer and glass fiber wrapping layer sequentially from the inside to the outside to form agriculture and fishery. Composite buoyancy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com